Preparation method of amphoteric ion exchange membrane

A technology of zwitterion and exchange membrane, applied in the field of preparation of zwitterion exchange membrane, can solve the problems of high membrane cost and unsuitable for large-scale production, etc., and achieve the effect of good chemical resistance stability and cost reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

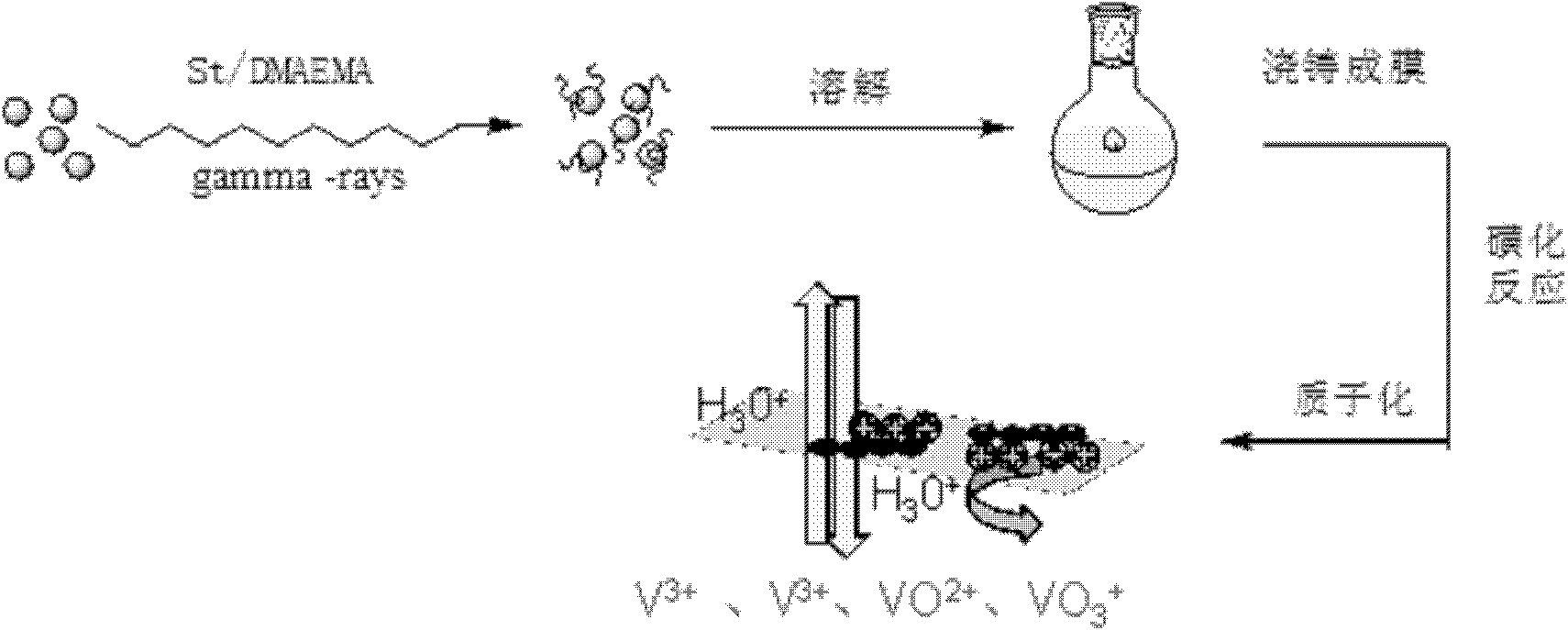

[0039] The polyvinylidene fluoride (PVDF) powder with a molecular weight of 430000 was immersed in a dichloromethane solution of 1mol / L styrene (St) and dimethylaminoethyl methacrylate (DMAEMA), and then used 60 Coγ-rays were irradiated at room temperature with an absorbed dose of 35 kGy, and the molar mass ratio of styrene (St) and dimethylaminoethyl methacrylate (DMAEMA) was 1:5. After the irradiation, the homopolymer and unreacted monomers were washed away with toluene and then dried for use.

[0040] Dissolve 2 g of the grafted powder in 100 mL of dimethylformamide solvent. The solution was heated and stirred in a 50°C water bath to obtain a transparent viscous solution. The viscous solution was poured on a flat and clean glass plate, dried at 60°C to form a film, and washed in deionized water. Subsequently, the membrane was immersed in a 0.2 mol / L chlorosulfonic acid dichloromethane solution for 12 hours to introduce a sulfonic acid group with a cation exchange function...

specific Embodiment 2

[0041] Immerse the polyvinylidene fluoride powder with a molecular weight of 430000 into the dichloromethane solution of 1mol / L styrene and dimethylaminoethyl methacrylate, and then use 60 Coγ-rays were irradiated at room temperature with an absorbed dose of 35 kGy, and the molar mass ratio of styrene and dimethylaminoethyl methacrylate was 1:5. After the irradiation, the homopolymer and unreacted monomers were washed away with toluene and then dried for use.

[0042] 2 g of the grafted powder was directly placed in a hot press, and hot pressed for 30 min under the conditions of 190° C. and 8 MPa to obtain a polymer membrane material. Subsequently, the membrane was immersed in a 0.2 mol / L chlorosulfonic acid dichloromethane solution for 12 hours to introduce a sulfonic acid group with a cation exchange function. Finally, the membrane was immersed in 1 mol / L hydrochloric acid aqueous solution for protonation reaction for 12 hours to obtain an amphoteric ion exchange membrane. ...

specific Embodiment 3

[0043] Put the polyvinylidene fluoride powder with a molecular weight of 430000 in the air, use 60 Coγ-rays were irradiated at room temperature with an absorbed dose of 15kGy and stored at -20°C. The irradiated powder was mixed with 1 mol / L monomer solution, and stirred and reacted in a water bath at 60°C for 6 hours, wherein the molar mass ratio of styrene and dimethylaminoethyl methacrylate was 1:5. After the reaction is completed, the homopolymer and unreacted monomers are washed away with toluene and then dried for use.

[0044] 2 g of the grafted powder was dissolved in 100 mL of dimethylformamide solvent, and 0.2 g of silica particles were added. The mixed solution was heated and stirred in a water bath at 50°C to make it uniform. The viscous mixed solution was poured on a flat and clean glass plate, dried at 60°C to form a film, and washed in deionized water. Subsequently, the membrane was immersed in a 0.2 mol / L chlorosulfonic acid dichloromethane solution for 12 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com