Long-range plasmon waveguide array synergy unit for solar cell

A technology of solar cells and waveguide arrays, applied to electrical components, circuits, light guides, etc., to achieve obvious synergistic effects, increase utilization, and improve absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

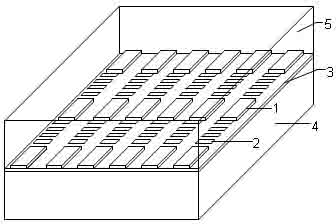

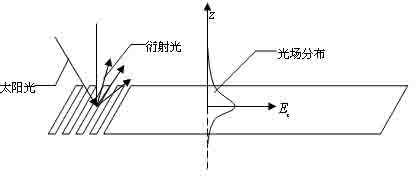

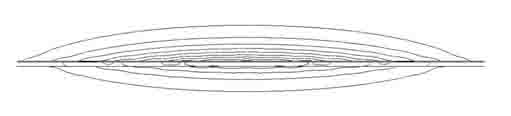

[0024] Example 1: Preparation of a long-range plasmonic waveguide array synergist unit. First, clean and polish the surface of the glass substrate to make the surface flatness at least less than 1 nm, and then use magnetron sputtering deposition, vacuum evaporation deposition, sol- A thin layer of indium tin oxide (ITO) is prepared on a glass substrate by one of the gel method, electrostatic spray-assisted vapor deposition method and high-current pulsed ion beam method, and the flatness is required to be not less than 2nm. The ITO glass is cleaned and dried again, and then a layer of positive photoresist ZPU450 is spin-coated on its surface, and a mask plate matching the metal waveguide array and diffraction grating structure is used for mask exposure. Then develop with a developer, and a photoresist pattern opposite to the structure of the metal waveguide array and the diffraction grating can appear on the surface of the ITO after development. Coating a layer of gold film on ...

Embodiment 2

[0025] Example 2: Preparation of photoanodes for dye-sensitized solar cells Utilize conventional preparation techniques such as sol-gel method, hydrothermal synthesis method, electrophoretic deposition method, magnetron sputtering method, etc. to prepare photoanodes required by the present invention (such as Figure 4 ). Firstly, the transparent conductive film 7 is prepared on the glass substrate 6, and the conductive material of the transparent conductive film is required to be indium tin oxide (ITO) with a thickness of 30-90 nm.

[0026]The semiconductor film is a porous nano film 8, the material is ZnO, and the diameter of the hole is 20-90nm. Then coat a layer of dye sensitizer 9 on the peninsula surface. The dye sensitizer is one of the bipyridine metal complex series, phthalocyanine series, porphyrin series, and pure organic dye series, and the bipyridine metal complex N719 is preferred.

Embodiment 3

[0027] Example 3: Preparation of solar cells Combining the above-mentioned long-range plasmonic waveguide array synergist unit with the photoanode of the dye-sensitized solar cell requires that the side of the photoanode with the dye sensitizer be combined with the side of the synergist unit with the electrolyte , the packaging is firm, and the preparation of the dye solar cell can be completed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com