Metal diffusion barrier layer between flexible metal substrate and back electrode of solar battery and fabrication method thereof

A technology of solar cells and metal diffusion, applied in the direction of circuits, electrical components, climate sustainability, etc., can solve the problems of high cost, shedding manufacturing cost, cracking of the solar cell barrier layer, etc., to achieve high bonding force, low cost production, high The effect of efficient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

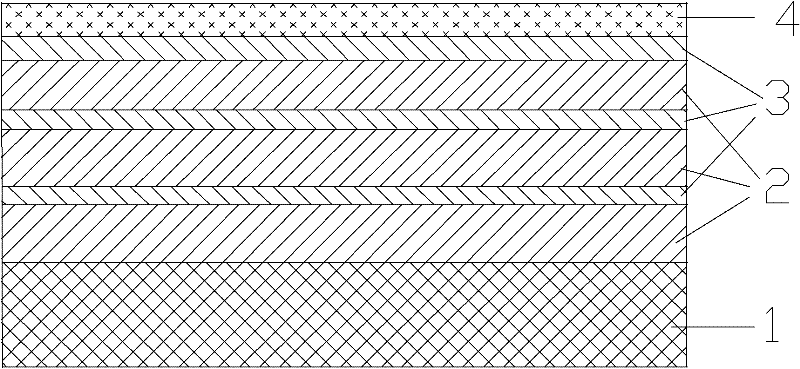

[0049] Use copper tape as the substrate

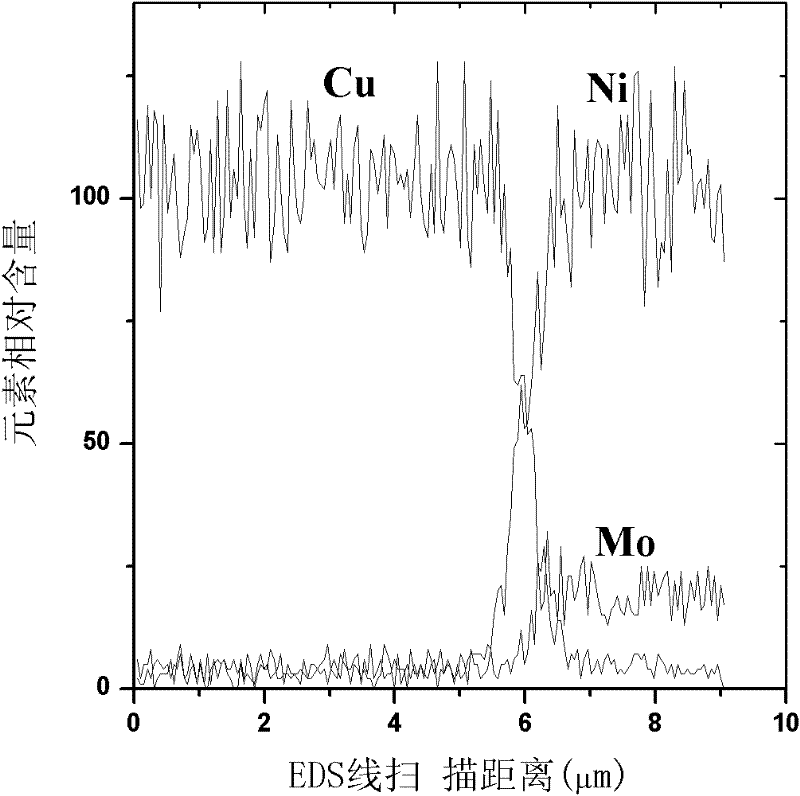

[0050] Put the copper strip on the continuous electroplating production line, and go through degreasing-activation-nickel plating-nickel-molybdenum alloy plating-nickel plating-nickel-molybdenum alloy plating-nickel plating-nickel-molybdenum alloy plating. Then, the plated strip is rapidly heat-treated in a protective atmosphere. The total thickness of the coating is 8 microns, the total number of layers is 16 layers, the thickness of each nickel coating is 0.8 microns, and the thickness of each nickel-molybdenum alloy coating is 0.2 microns.

[0051] Degreasing conditions:

[0052] Sodium hydroxide 30g / L, sodium carbonate 40g / L, sodium phosphate 30g / L, sodium silicate 8g / L, oil removal temperature: 80°C.

[0053] Activation conditions:

[0054] Sulfuric acid: 40g / L, activation temperature: room temperature.

[0055] Nickel plating conditions: Ultrasonic direct current electroplating

Embodiment 2

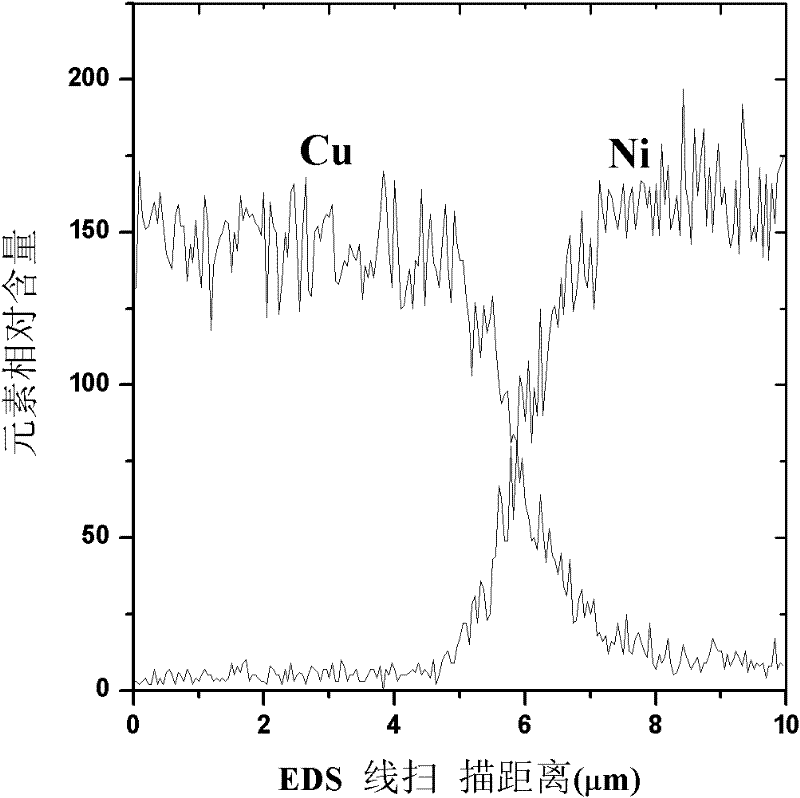

[0062] The stainless steel strip is selected as the substrate, and it undergoes pre-plating pretreatment—nickel plating—nickel-molybdenum alloy plating—nickel plating—nickel-molybdenum alloy plating—nickel plating—nickel-molybdenum alloy plating. Then, the plated strip is rapidly heat-treated in a protective atmosphere. The total thickness of the coating is 9 microns, the total number of layers is 12 layers, the thickness of each nickel coating is 1 micron, and the thickness of each nickel-molybdenum alloy coating is 0.5 micron.

[0063] Wherein the conditions of nickel plating, nickel-molybdenum alloy plating and the conditions of rapid heat treatment are the same as in Example 1.

[0064] Pre-plating pretreatment is conventional stainless steel pre-plating pretreatment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com