Dual-core-shell silicate luminescent material and preparation method thereof

A technology of luminescent materials and silicates, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of low luminous efficiency, uniform luminescence performance and stability that cannot meet actual needs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

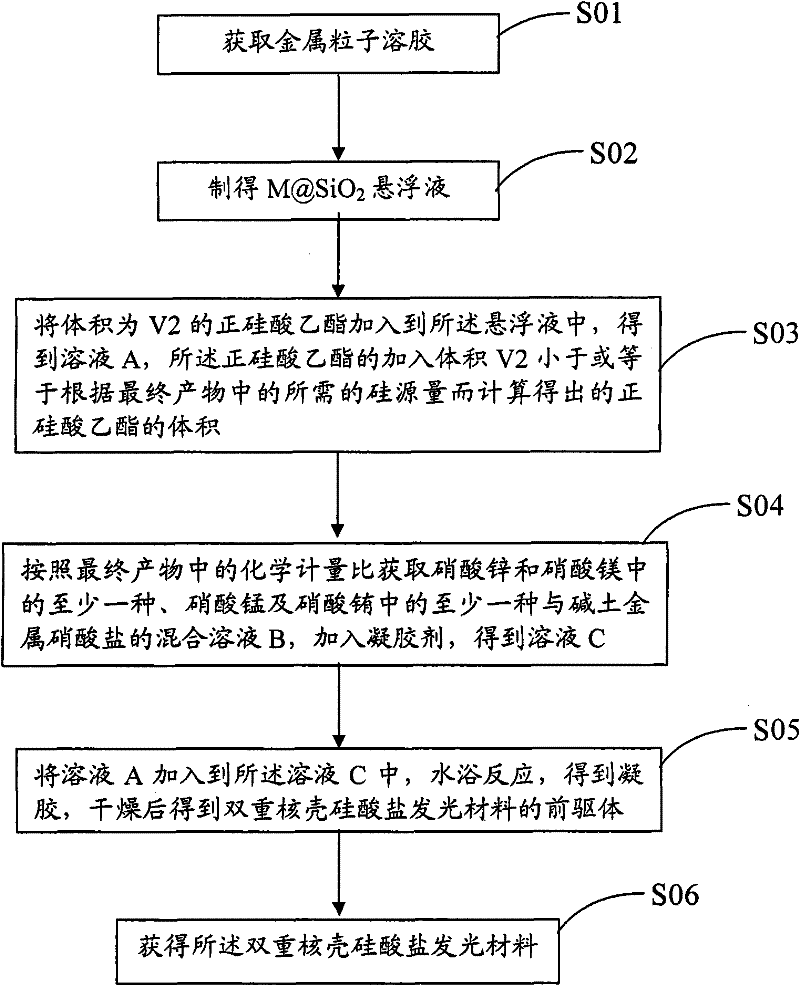

[0030] see figure 1 , illustrating the process flow of the preparation method of the double core-shell silicate luminescent material according to the embodiment of the present invention, including the following steps:

[0031] S01, obtaining metal particle sol;

[0032] S02, after diluting the metal particle sol, add an alcohol solvent and a weak alkaline solution, stir, add tetraethyl orthosilicate to react, and obtain a suspension of metal particles coated with silicon dioxide as the inner shell, that is, MSiO 2 suspension;

[0033] S03, adding tetraethyl orthosilicate with a volume of V2 to the suspension to obtain solution A, the added volume V2 of the orthosilicate is less than or equal to the required amount of silicon source in the final product Calculated volume of tetraethyl orthosilicate;

[0034] S04, obtain a mixed solution B of at least one of zinc nitrate and magnesium nitrate, at least one of manganese nitrate and europium nitrate and alkaline earth metal nit...

Embodiment 1

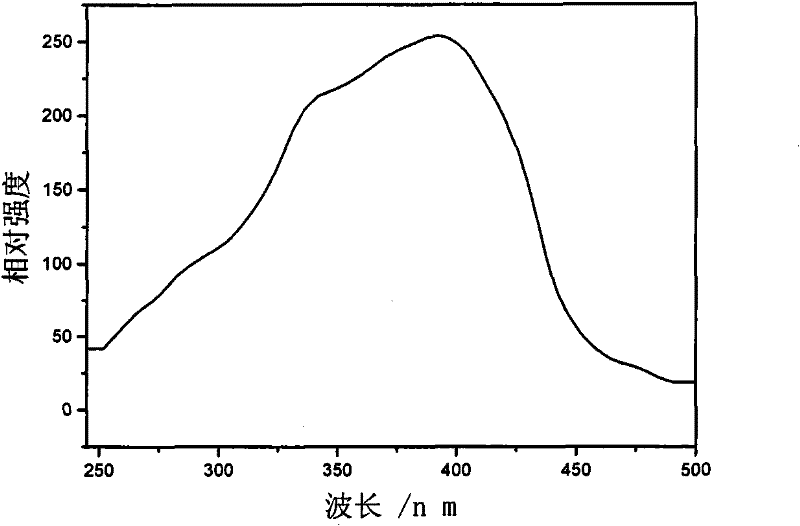

[0054] The preparation of Pt nanoparticle sol: take by weighing 5.18mg chloroplatinic acid (H 2 PtCl 6 ·6H 2 O) be dissolved in the deionized water of 17mL; After chloroplatinic acid dissolves completely, take by weighing 8.0mg sodium citrate and 12.0mg sodium dodecylsulfonate, and dissolve in the chloroplatinic acid aqueous solution under the environment of magnetic stirring , to obtain chloroplatinic acid solution; weigh 0.38mg sodium borohydride and dissolve it in 10mL deionized water to obtain 10mL concentration of 1×10 -3 mol / L sodium borohydride aqueous solution, while preparing 10mL concentration of 1×10 -2 mol / L hydrazine hydrate solution; in the environment of magnetic stirring, first drop 0.4mL sodium borohydride aqueous solution into the chloroplatinic acid solution, stir for 5min, and then add dropwise 2.6mL 1×10 -2 mol / L hydrazine hydrate solution, and then continue to react for 40min to obtain 20mL Pt content of 5×10 -4 mol / L Pt nanoparticle sol; then measure...

Embodiment 2

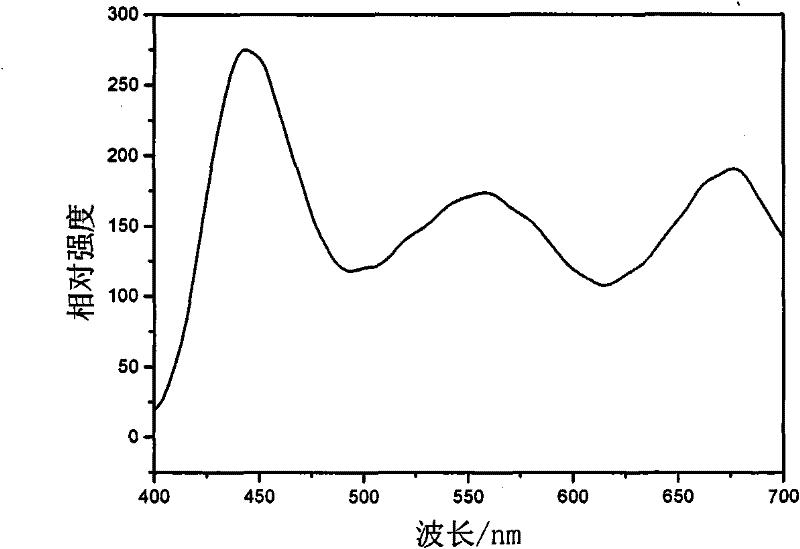

[0058] Preparation of Au nanoparticle sol: Weigh 4.12 mg of chloroauric acid (AuCl 3 ·HCl·4H 2 O) be dissolved in the deionized water of 8.4mL; After chloroauric acid is completely dissolved, take by weighing 14mg sodium citrate monohydrate and 6mg cetyltrimethylammonium bromide, and dissolve to chlorine under the environment of magnetic stirring Auric acid aqueous solution was obtained to obtain a chloroauric acid solution; 1.9 mg of sodium borohydride and 17.6 mg of ascorbic acid were weighed and dissolved in 10 mL of deionized water respectively to obtain a concentration of 10 mL of 5×10 -3 mol / L sodium borohydride aqueous solution and 10mL concentration is 1×10 -2 mol / L ascorbic acid aqueous solution; in the environment of magnetic stirring, first add 0.04mL sodium borohydride aqueous solution to the chloroauric acid solution, stir and react for 5 minutes, then add 1.56mL1×10 -2 mol / L ascorbic acid aqueous solution, and then continue to react for 30min to obtain 10mL Au ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com