Electrochemical device and inorganic/organic composite porous membrane

A porous and organic technology, which is applied in the preparation of inorganic/organic composite porous films, electrochemical devices and the field of inorganic/organic composite porous films, can solve the problem of insufficient electrolyte diaphragm, reduced lithium ion conductivity, electrolyte It takes a long time to disperse, etc., to achieve good electrolyte wetting and absorption capacity, excellent lithium ion conductivity, and improve the effect of poor thermal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] 1-1. Inorganic / organic composite porous film (Al 2 o 3 / PAA-PAAS) preparation

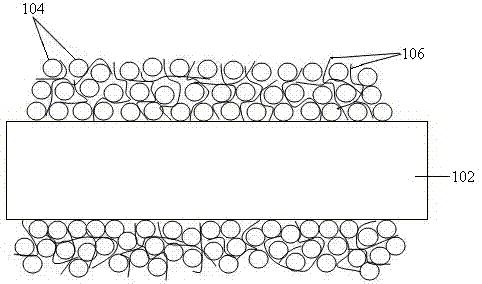

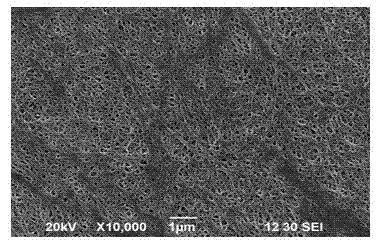

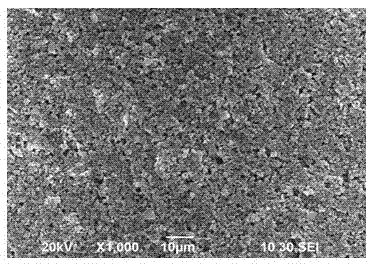

[0063] Add about 50wt% Al to deionized water 2 o 3 The powder was stirred for 1 hour, and then a PAA-PAAS (Polyacrylic acid-Sodium polyacrylate) aqueous solution (the content of PAA-PAAS in the aqueous solution was 25wt%) was added with a solid content of 5wt% and stirred for 1 hour, Grind in a ball mill for 1 hour, then add a CMC solution with a solid content of 0.5 wt% to the ground slurry, and continue stirring for 1 hour to prepare a slurry. Then use a reverse roll gravure coater to uniformly coat the prepared above slurry on a polyethylene microporous film (45% porosity) with a thickness of 20 μm, the coating thickness is 5 μm thick, repeat this step to obtain a thickness of 5 μm thick The total thickness of the other coating layer, that is, the composite porous film is 30 μm. The composite porous film was measured with a mercury porosimeter, and its porosity was 45%, which was bas...

Embodiment 2

[0069] 2-1. Inorganic / organic composite porous film (Al 2 o 3 / PAA-PAAS / CR) preparation

[0070] Add about 50wt% Al to deionized water 2 o 3 The powder was stirred for 1 h, and then an aqueous silane coupling agent (3-glycidyl ether propyltriethoxysilane) with a content of 5 wt % in terms of solid content and a water-based silane coupling agent (3-glycidyl ether propyl triethoxysilane) with a content of 3 wt % in terms of solid content was added, and After stirring for 1 hour, grind in a ball mill for 1 hour, add a CMC solution with a solid content of 1.0 wt % to the ground slurry, and continue stirring for 1 hour to obtain a slurry. The polypropylene microporous film needs to be pre-treated by corona or other surface treatment methods that can increase the surface tension of the film, and then use a precision slit extrusion coater to evenly coat the slurry prepared by the above method on a surface with a thickness of 20 μm On the polypropylene microporous film (porosity 4...

Embodiment 3

[0073] 3-1. Inorganic / organic composite porous film (SiO 2 / Al 2 o 3 / PAA-PAAS / CR) preparation

[0074] Add about 40wt% Al to the deionized water 2 o 3 powder and 10wt% SiO 2 The powder was stirred for 1 h, then a PAA-PAAS aqueous solution with a solid content of 5 wt % and a silane coupling agent (3-glycidyl ether propyl trimethoxysilane) with a solid content of 3 wt % was added, and stirred After 1 hour, grind in a ball mill for 1 hour, then add a CMC solution with a solid content and a content of 0.5 wt% to the ground slurry, and continue stirring for 1 hour to obtain a slurry. The polypropylene microporous film needs to be pre-treated by corona or other surface treatment methods that can increase the surface tension of the film, and then use the reverse roll gravure coater to coat the slurry prepared as above on the polypropylene film with a thickness of 20 μm. On the microporous film (porosity 45%), the coating thickness is 5 μm thick, and this step is repeated to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decomposition temperature | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com