Concentration and cold-precipitation separation method of sodium sulfate and ammonium sulfate from vanadium-precipitation mother liquor high-salt wastewater

A high-salt wastewater and separation method technology, applied in the direction of alkali metal sulfite/sulfate purification, ammonium sulfate, chemical instruments and methods, etc., can solve the problem that the return to production and utilization cannot meet the reuse requirements, and the wastewater cannot meet the requirements to waste water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

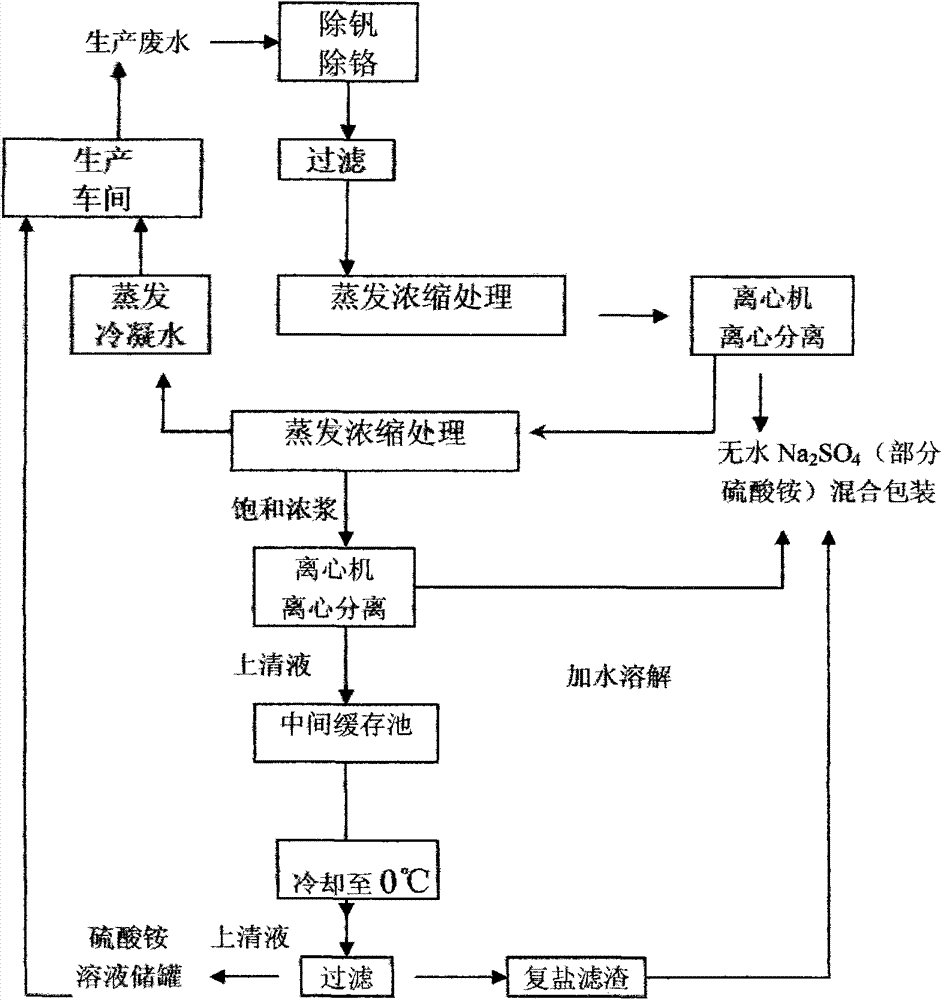

[0011] The process flow of the invention is attached figure 1 The basic process of the present invention is as follows:

[0012] After removing vanadium, chromium and filtering, the mother liquor of waste water enters the concentration evaporation system, and evaporates at 75℃ until ammonium sulfate is unsaturated and part of sodium sulfate is saturated. The saturated sodium sulfate slurry is discharged from the concentration system and enters the centrifuge for centrifugal separation. Partially pure anhydrous sodium sulfate crystals; the remaining liquid enters the next effect. Continue to evaporate at 65°C until the ammonium sulfate is close to saturation. Sodium sulfate crystallizes out again, and the anhydrous sodium sulfate is separated by centrifugation; after sodium sulfate is separated, the remaining concentrated slurry is The co-saturated solution of sodium sulfate and ammonium sulfate enters the intermediate buffer pool, where it is cooled and further frozen to 0℃~5℃, an...

Embodiment 2

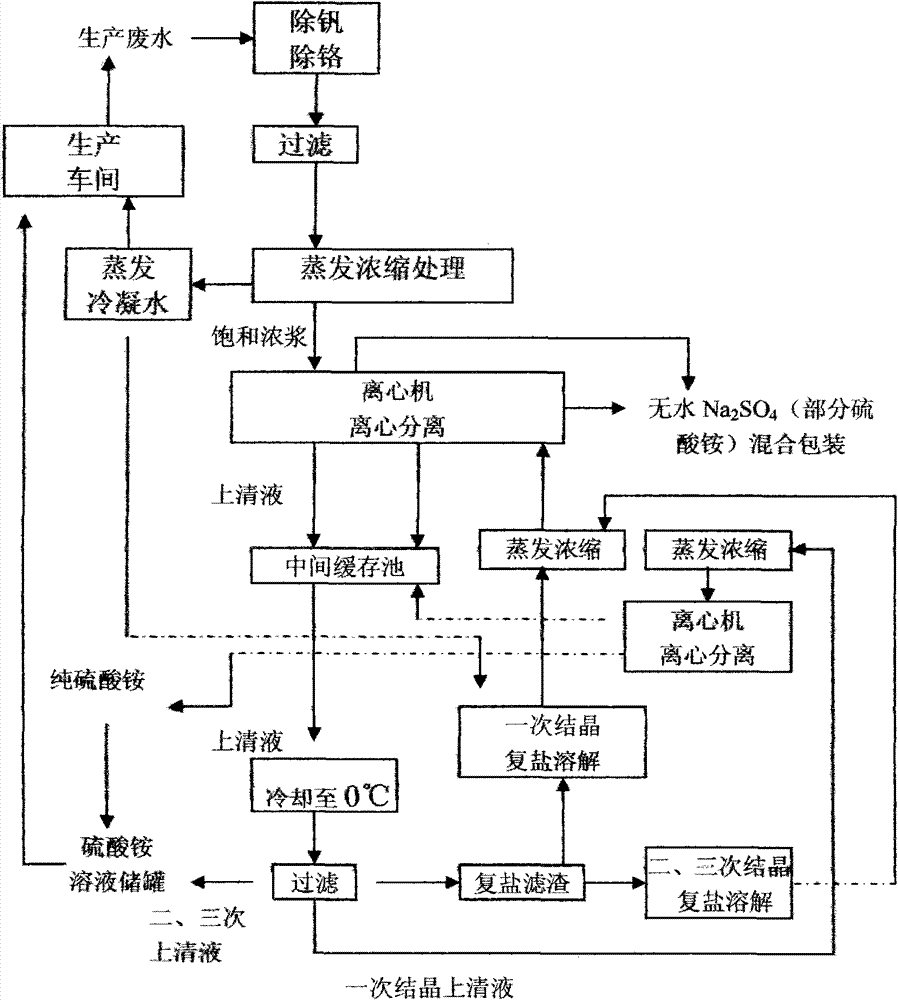

[0014] The process flow of the invention is attached figure 2 The basic process of the present invention is as follows:

[0015] 1. After vanadium and chromium removal, the vanadium precipitation wastewater with heavy metal content up to the standard is filtered, and the clarified supernatant enters the evaporation concentration system for concentration and evaporation;

[0016] 2. The evaporative concentration system is a multi-effect evaporation. According to the phase diagram data of sodium sulfate and ammonium sulfate (sodium chloride can be temporarily ignored due to its low content, but should be considered appropriately when the system is selected), the wastewater is first Evaporate at ℃ until the ammonium sulfate is unsaturated and part of the sodium sulfate is saturated, so that part of the sodium sulfate crystallizes out, centrifuged to obtain pure anhydrous sodium sulfate crystals; the remaining liquid enters the next effect, and the system materials continue to evapora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com