Method for preparing spherical activated carbon

A spherical activated carbon, carbon powder technology, applied in chemical instruments and methods, climate sustainability, sustainable manufacturing/processing, etc., can solve the problems of raw material waste, low water capacity, large pressure drop, etc., to reduce pollution, The effect of saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment one: The preparation method of spherical activated carbon includes coal powder and coal tar pitch powder, and the production process steps are as follows:

[0041] 1. Milling: Grinding the coal powder to a fineness of 200 mesh, with a passing rate of 95%, and grinding the coal tar pitch to a fineness of 325 mesh, with a passing rate of 98%;

[0042] 2. Mixing: Mix the prepared coal powder and coal tar pitch powder at a ratio of 100:20 for 8-12 minutes, then add 10-12% modified water and mix for 8-12 minutes;

[0043] The preparation method of modified water is: (1) Heating tap water to 40-50°C. ⑵While stirring, add 0.3~0.5% of alkylphenol polyoxyethylene ether or lignosulfonate to fully dissolve; ⑶While stirring, add 0.3~0.5% of polyanionic cellulose sodium and let it stand for 8 hours Make it dissolve, then stir to make it fully dissolved;

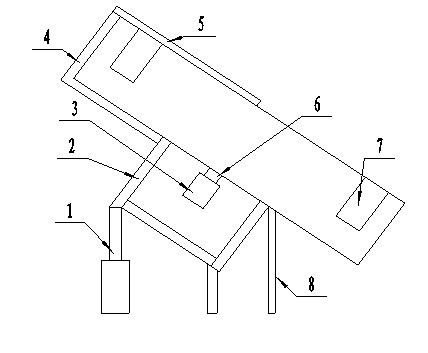

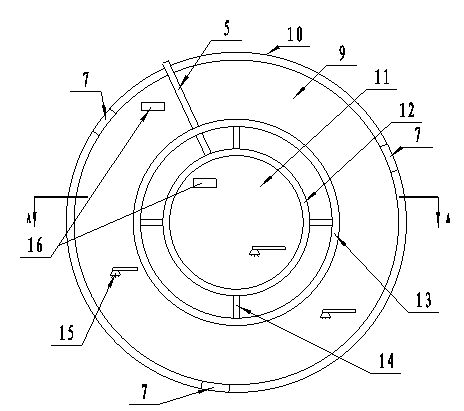

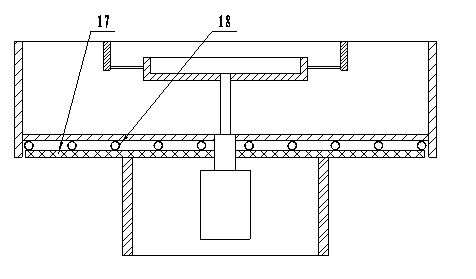

[0044]3. Ball making: After the dribbling machine is started and running normally, add the mixed raw materials int...

Embodiment 2

[0048] Embodiment two: The preparation method of spherical activated carbon includes coal powder and coal tar pitch powder, and the production process steps are as follows:

[0049] 1. Milling: Grinding the coal powder to a fineness of 325 mesh, with a pass rate of 90%, and grinding the coal tar pitch to a fineness of 625 mesh, with a pass rate of 90%.

[0050] 2, 3, 4, 5, 6 process conditions are the same as in Example 1.

Embodiment 3

[0051] Embodiment three: The preparation method of spherical activated carbon comprises charcoal powder and coal tar pitch powder, and the production process steps are as follows:

[0052] 1. Flour making: Grind charcoal to 200 meshes, with a passing rate of 95%, and grind coal tar pitch to 325 meshes, with a passing rate of 98%.

[0053] 2, 3, 4, 5, 6 process conditions are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com