A kind of micro/nano fiber sustained-release preparation for treating scar and preparation method thereof

A slow-release preparation and nanofiber technology, applied in the field of biomedicine, can solve the problems of ginsenoside Rg3 being difficult to disperse uniformly, difficult to achieve effective absorption of slow-release drugs, and limited solubility, so as to protect and inhibit drug molecule desorption, good Small molecule size effect, effect of improving dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Mix 100mg of ginsenoside Rg3 into 1g of trifluoroacetic acid, stir until slowly and fully dissolved to form a transparent solution; fully dissolve 1g of polylactic acid (PLLA) in 3g of methylene chloride to obtain a transparent and uniform solution; Slowly added dropwise into the stirred PLLA solution to obtain a transparent drug and polymer mixed electrospinning solution.

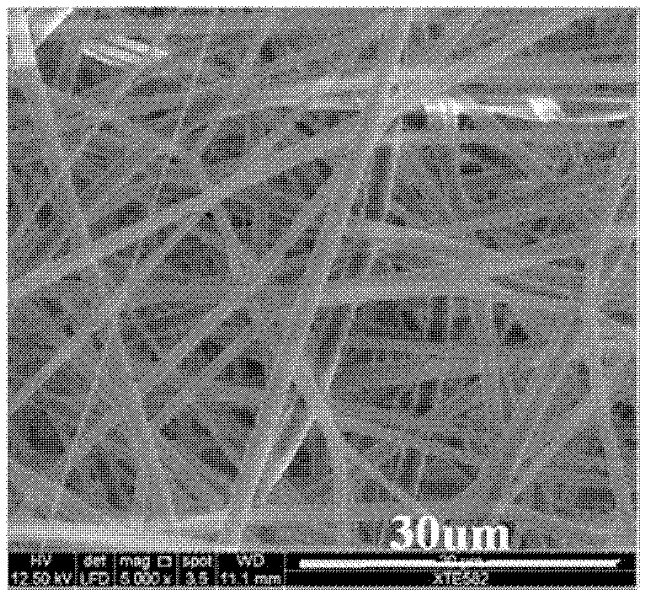

[0057] Set the voltage of electrospinning technical parameters to 10KV, the flow rate to 0.6ml / min, the distance from the needle to the collecting plate to 15cm, the temperature to 25°C and the relative humidity to 50%. The collected film-shaped fiber aggregate sustained-release preparation was vacuum-dried for 2 days to obtain a film-shaped fiber aggregate sustained-release preparation containing ginsenoside Rg3 drug. Obtain the scanning electron micrograph of film-shaped fiber aggregate slow-release preparation as figure 1 shown. Among them, the film-like fiber aggregate sustained-release prepar...

Embodiment 2

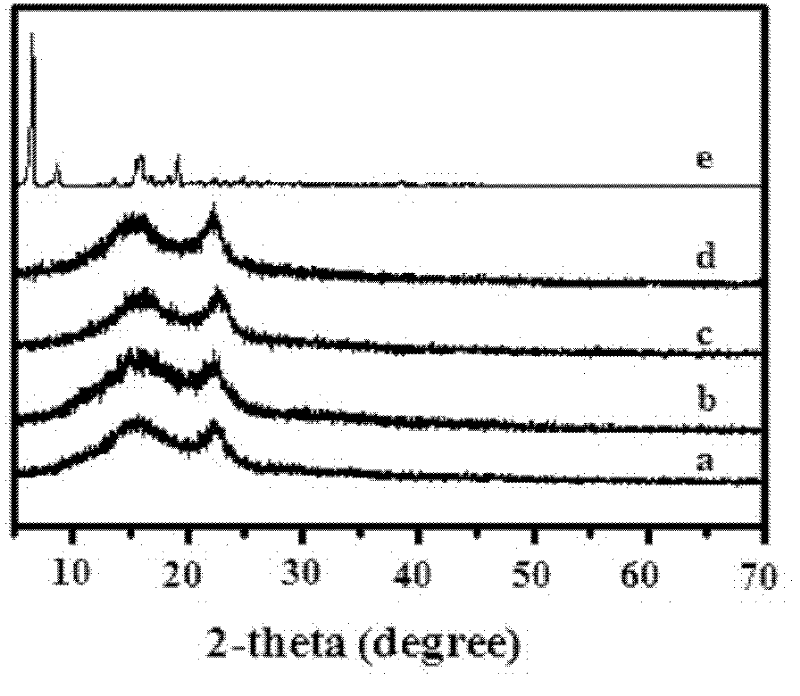

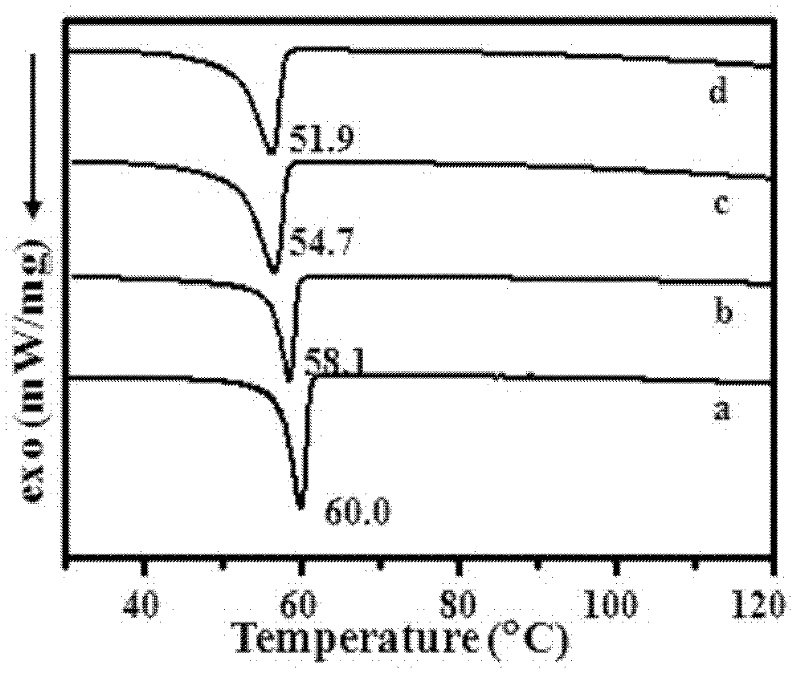

[0059]Add a certain amount of 20mg, 60mg, and 100mg of ginsenoside Rg3 into 1g of hexafluoroisopropanol, stir until slowly and fully dissolved to form a transparent solution; fully dissolve 1g of polylactic acid (PLLA) in 3g of chloroform, respectively, Obtain a transparent and uniform solution; then slowly add three kinds of ginsenoside Rg3 solutions to the stirred three PLLA solutions respectively to obtain a transparent drug and polymer mixed electrospinning solution, according to the mass ratio of ginsenoside Rg3 and PLLA , the contents of ginsenoside Rg3 were prepared to be 2%, 6% and 10% of the polymer content respectively. By adjusting the technical parameters of electrospinning and using a flat plate as a collector, two-dimensional micro / nano fiber membranes are collected, and the collected fibers are vacuum-dried for 2 days at room temperature to obtain controllable release of ginsenoside Rg3. 6% and 10% biodegradable micro / nanofiber membrane formulations.

[0060] A...

Embodiment 3

[0064] This example is the same as Example 1, the only difference is that polyethylene glycol with a molecular weight of 2000 is added to each gram of PLLA solution, and the polyethylene glycol is 50 mg of the mass ratio of PLLA to obtain a controllable release of ginsenoside Rg3 drug The biodegradable polymer PLLA micro / nanofiber membrane preparation was continuously spun and collected by multiple grams of PLLA fibers, using a flat plate as a collector, and a fiber membrane with a thickness of 1 mm was collected.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com