Tourmaline integral honeycomb ceramic and preparation method thereof

A technology of honeycomb ceramics and tourmaline, which is applied in the field of tourmaline monolithic honeycomb ceramics, can solve problems such as complex process, low treatment efficiency, and small specific surface area, and achieve good treatment effect, good treatment effect, and high specific surface area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

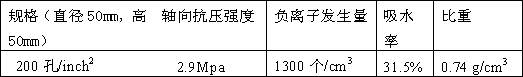

Image

Examples

Embodiment 1

[0028] Example 1, the tourmaline monolithic honeycomb ceramics is composed of lithium tourmaline, ball clay, frit, diatomaceous earth, sepiolite, and magnesia clay, and its raw material formula (percentage by weight): lithium tourmaline 32, ball clay 5, frit 30, diatomite 10, sepiolite 18, magnesia clay 5, add the carboxymethyl cellulose of above-mentioned raw material gross weight 12%, and the wax emulsion of 5%, 2 % stearic acid emulsion and 4% glycerin.

[0029] Prepared according to the following preparation method steps:

[0030] a. After accurately weighing lithium tourmaline, ball clay, frit, diatomaceous earth, sepiolite, magnesia clay, and carboxymethyl cellulose, add them in proportion to the media mill for mixing and crushing to form a mixture;

[0031] b. Put the mixed material into the kneader, add appropriate amount of water, wax emulsion, stearic acid emulsion and glycerin in proportion while stirring, and mix well for no less than 20 minutes to form mud;

[0...

Embodiment 2

[0045] Embodiment 2. The tourmaline monolithic honeycomb ceramics is composed of magnesium tourmaline, bentonite, finely ground lepidolite, frit, silica sol, medical stone, etc., and its raw material formula (weight percentage): magnesium electrical Stone 40, bentonite 4, finely ground lepidolite 7, frit 21, silica sol 3 (using SiO 2 dry basis), medical stone 25,

[0046] Add 4% hydroxypropyl methylcellulose, 4% tung oil, and 6% edible oil to the total weight of the above raw materials.

[0047] Add the charcoal powder of above-mentioned raw material gross weight 2% again.

[0048] Prepared according to the following preparation method steps:

[0049] a. After accurately weighing magnesium tourmaline, bentonite, medical stone, lepidolite, frit, hydroxypropyl methylcellulose, and charcoal powder, add them to a media mill in proportion to pulverize and mix to form a mixture;

[0050] b. Put the mixed material into the kneader, and add quantitative water, tung oil, and edible ...

Embodiment 3

[0062] Embodiment 3, described tourmaline monolithic honeycomb ceramic, is made up of magnesium tourmaline and ferrite, frit, bentonite and rectorite, dolomite, sepiolite and zeolite, and the formula (weight percentage) of its raw material: magnesium Tourmaline and Ferrite 36 (50% each), Bentonite 4, Rectorite 3, Dolomite 8, Frit 30, Sepiolite 15, Zeolite 4,

[0063] Add the carboxymethyl cellulose of above-mentioned raw material gross weight 8% and the glycerin of 7% and the tung oil of 7% again.

[0064] Then add the pulverized coal of above-mentioned raw material gross weight 3%.

[0065] Prepared according to the following preparation method steps:

[0066] a. Accurately weigh magnesium and ferrite tourmaline, frit powder, bentonite and rectorite, dolomite, sepiolite and zeolite, carboxymethyl cellulose and coal powder, and then add them to the media mill in proportion to pulverize and mix form a mixture;

[0067] b. Put the mixture into the kneader, add appropriate amo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com