A kind of oral pegylated insulin pH-sensitive nanoparticles and preparation method thereof

A technology of PEGylation and polyethylene glycol butyraldehyde is applied in pharmaceutical formulations, medical preparations without active ingredients, and medical preparations containing active ingredients. Poor drug absorption ability, no pH sensitivity and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) Phacoemulsification to prepare W / O colostrum of PEGylated insulin, pH-sensitive polymer and carrier material: Weigh 40 mg of starch and dissolve it in 40 mL of deionized water to obtain a starch solution with a mass fraction of 0.1%. PEGylated insulin was dissolved in 0.5 mL of the above starch solution to form an internal aqueous phase; 1 mL of acetone and 4 mL of methylene chloride were mixed, and 50 mg of hydroxypropylmethylcellulose phthalate (abbreviation: HP55) was added to it Dissolve with 50mg polylactide (abbreviation: PLGA) to form an oil phase; mix 0.5mL internal water phase with 5mL oil phase, and ultrasonically emulsify at 40W for 0.5min to obtain W / O colostrum;

[0036] (2) Ultrasonic dispersion of W / O colostrum in the stabilizer solution to form W / O / W double emulsion: Weigh 100mg of polyvinyl alcohol (abbreviation: PVA), dissolve it in 10mL of deionized water, and form a PVA mass fraction of 1% The external water phase; mix 10mL of the external water ...

Embodiment 2

[0041] (1) Phacoemulsification to prepare W / O colostrum of PEGylated insulin, pH-sensitive polymer and carrier material: Weigh 200 mg of glycerol and add it into 40 mL of deionized water to obtain a glycerol solution with a mass fraction of 0.5%. PEGylated insulin was dissolved in 0.5mL of the above glycerin solution to form an internal water phase; 1mL of acetone and 4mL of dichloromethane were mixed, and 100mg of HP55 and 100mg of polylactic acid (PLA) were added to dissolve to form an oil phase; 0.5 Mix mL internal water phase and 5 mL oil phase, and ultrasonically emulsify at 40W for 4min to obtain W / O colostrum;

[0042] (2) Ultrasonic dispersion of W / O colostrum in stabilizer solution to form W / O / W double emulsion: Weigh 600mg of PVA and dissolve it in 20mL of deionized water to form an external aqueous phase with a mass fraction of PVA of 3%; Mix the external water phase with 5.5mL of W / O colostrum obtained in step (1), and ultrasonically emulsify at 60W for 2min to obt...

Embodiment 3

[0047] (1) Prepare W / O colostrum of PEGylated insulin, pH-sensitive polymer and carrier material by ultrasonic emulsification: Weigh 0.1 g of starch and dissolve it in 40 mL of deionized water to obtain a starch solution with a mass fraction of 0.25%. 10 mg of pegylated insulin was dissolved in 0.5 mL of the above starch solution to form an internal water phase; 1 mL of acetone and 4 mL of methylene chloride were mixed, and 100 mg of HP55 and 50 mg of PLGA were added to dissolve to form an oil phase; 0.5 mL of the internal water phase Mix with 5mL oil phase, 50W ultrasonic emulsification for 4min, get W / O colostrum;

[0048] (2) Ultrasonic dispersion of W / O colostrum in stabilizer solution to form W / O / W double emulsion: Weigh 0.8g of PVA and dissolve it in 40mL of deionized water to form an external aqueous phase with a mass fraction of PVA of 2%; Mix 40mL of the external water phase with 5.5mL of the W / O colostrum obtained in step (1), and ultrasonically emulsify at 50W for 4...

PUM

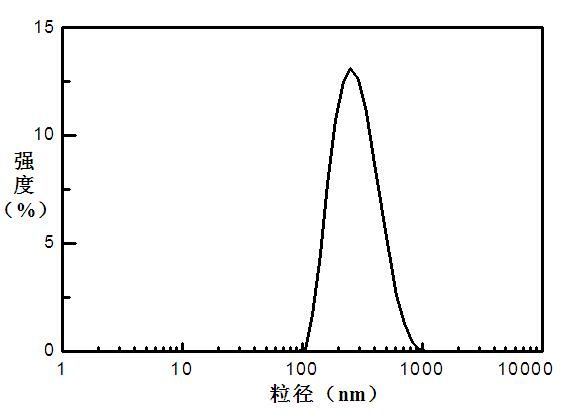

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com