Method for compounding double-layer plating films on plastic surface by fully dry method

A double-layer composite and all-dry technology, which is applied in chemical instruments and methods, metal material coating technology, coatings, etc., can solve the problems of lack of metal texture, large amount of metal consumption, high water and energy consumption, etc. Achieve the effect of hard and smooth surface, less metal consumption, and improved gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

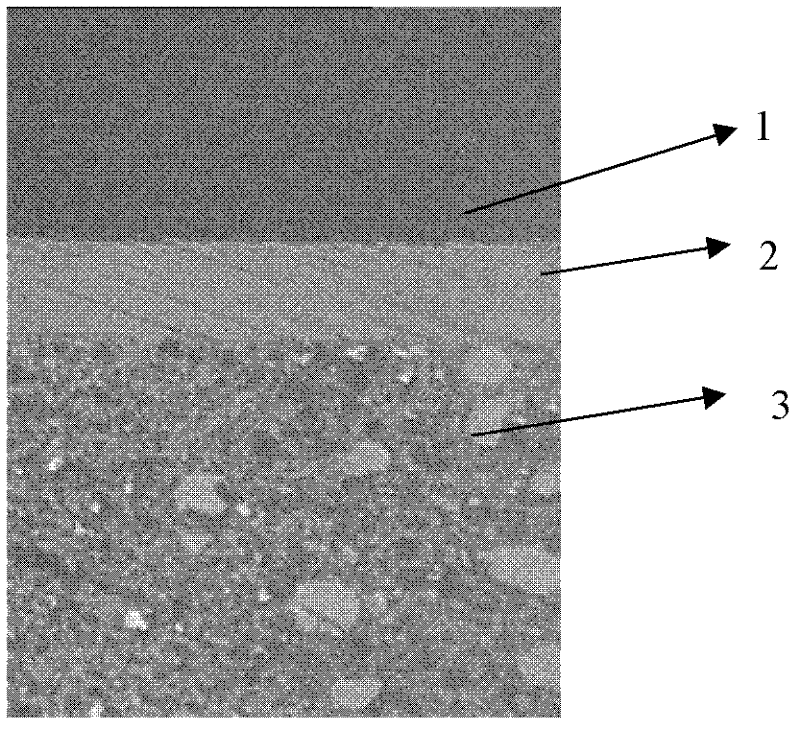

Image

Examples

Embodiment 1

[0027] Embodiment 1 A kind of ABS material hexavalent chrome light chrome faucet

[0028] 1) The ABS masterbatch with silvery white treatment is injected into the blank, wiped with a dry cloth, then flame cleaned and activated, and then electrostatically dedusted. The flame treatment time is 4s.

[0029] 2) Spray a layer of 20 μm thick UV-curable coating on the workpiece after cleaning. Heating and leveling with infrared light (60℃×8min), and then cured by ultraviolet light (1000J / m 2 ×40s).

[0030] 3) Transfer the blanks sprayed with UV-curable coatings into a PVD (Physical Vapor Deposition) furnace for plasma gas activation (conditions: ion source current 0.3A, bias voltage 100V, furnace vacuum pressure 0.2Pa, working air flow of Ar 2 and O 2 Mixed air flow, mixing ratio 50SCCM: 50SCCM, activation time 5min); then a layer of metal film Cr with a thickness of 0.1 μm is deposited on the paint surface (arc coating conditions: chromium target current 80A, bias voltage 70V, 3...

Embodiment 2

[0040] Embodiment 2 A kind of nylon material plated imitation gold handle

[0041] 1) The PA masterbatch with golden treatment is injected into the blank, wiped with a dry cloth, then flame cleaned and activated, and then electrostatically removed. The flame treatment time is 12s.

[0042]2) Spray a layer of 30μm thick thermosetting coating, use leveling temperature (60℃×15min), and then cure (80℃×25min).

[0043] 3) Transfer the coated blank into a PVD (Physical Vapor Deposition) furnace for plasma gas activation (conditions: ion source current 0.3A, bias voltage 100V, furnace vacuum pressure 0.2Pa, working gas flow of Ar 2 and O 2 Mixed air flow, mixing ratio 70SCCM: 30SCCM, activation time 5min); then a layer of metal film Zr with a thickness of 0.1 μm is coated on the paint surface (arc coating conditions: zirconium target current 120A, bias voltage 70V, 50SCCM Ar 2 , vacuum pressure 0.2Pa, coating time 2min), and then a layer of 0.3um zirconium nitride film (arc coating...

Embodiment 3

[0052] Embodiment 3 A kind of BMC material stainless steel color refrigerator handle

[0053] 1) Injection-molded BMC pellets with stainless steel color treatment, wiped with a dry cloth, then flame cleaned and activated, and then electrostatically dedusted. The flame treatment time was 15s.

[0054] 2) The workpiece is preheated to 120 degrees, spray a layer of 50μm thick heat-cured coating, the heat-cured coating is preheated at a temperature of (130°C×5min), then leveled (150°C×5min), and then cured (170°C×20min) ).

[0055] 3) Transfer the coated blank into a PVD (Physical Vapor Deposition) furnace for plasma gas activation (conditions: ion source current 0.3A, bias voltage 120V, furnace vacuum pressure 0.2Pa, working gas flow of Ar 2 and O 2 Mixed air flow, mixing ratio 50SCCM: 100SCCM, activation time 5min); then coat a layer of metal film Zr with a thickness of 0.1μm on the paint surface (arc coating conditions: zirconium target current 120A, bias voltage 70V, 50SCCM ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pencil hardness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Pencil hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com