Foliage conditioner prepared from straw and household kitchen biomass carbonization byproducts and application thereof

A technology of biomass charcoal and conditioner, applied in the directions of plant growth regulator, application, biocide, etc., to achieve the effect of enhancing resistance, alleviating tomato continuous cropping obstacles, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

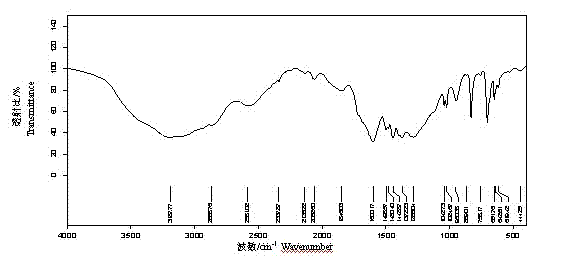

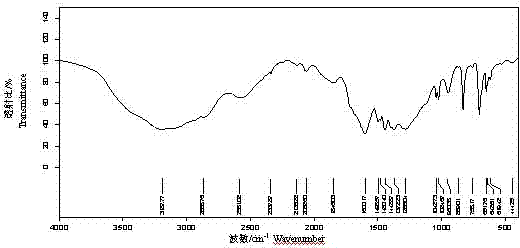

Image

Examples

Embodiment 1

[0039] A foliar conditioner utilizing carbonization by-products of straw and remaining living room biomass, characterized in that the foliar conditioner is prepared as follows:

[0040] A. The straw and living cabinet residual biomass are dried to make m (water) < 10%, and then the obtained dry matter is ground to make the particle size < 3mm. The raw materials are put into pyrolysis equipment, and the carbonization temperature is 400~500 ℃ for anaerobic pyrolysis. After 2 hours of pyrolysis, it is separated by a separation device, and the collected liquid is filtered after static precipitation to obtain a stock solution of wood vinegar;

[0041] B. After standing for 1 week, filter through a microporous membrane to obtain a refined wood vinegar mixture. The pH of the refined wood vinegar mixture is 9.37, and the total organic carbon TOC content is 3.87 g·L-1.

Embodiment 2

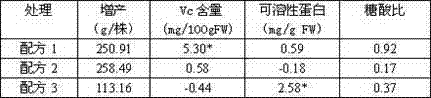

[0043] 1. Formula of straw and wood vinegar foliage conditioner:

[0044] Recipe 1: 3.33g of refined mixture of straw and wood vinegar, mixed with 1kg of water, directly diluted.

[0045] Formula 2: urea 1.36g, potassium dihydrogen phosphate 0.34g, ammonium molybdate 0.034g, zinc sulfate 0.068g, copper sulfate 0.068g, boric acid 0.034g, magnesium sulfate 0.136g, ferrous sulfate 0.204g, manganese sulfate 0.034g, Calcium chloride 0.34g, EDTA 0.2728g, water 1kg; when preparing, first dissolve each component with the minimum amount of water according to the above proportions to obtain the aqueous solution of each component, then mix the EDTA aqueous solution with the ferrous sulfate aqueous solution, Then the aqueous solutions of other components were slowly added to the mixed solution of EDTA and ferrous sulfate, stirred while adding, and finally the obtained mixed solution was constant volume.

[0046] Formula 3: 3.33g refined mixture of straw and wood vineg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com