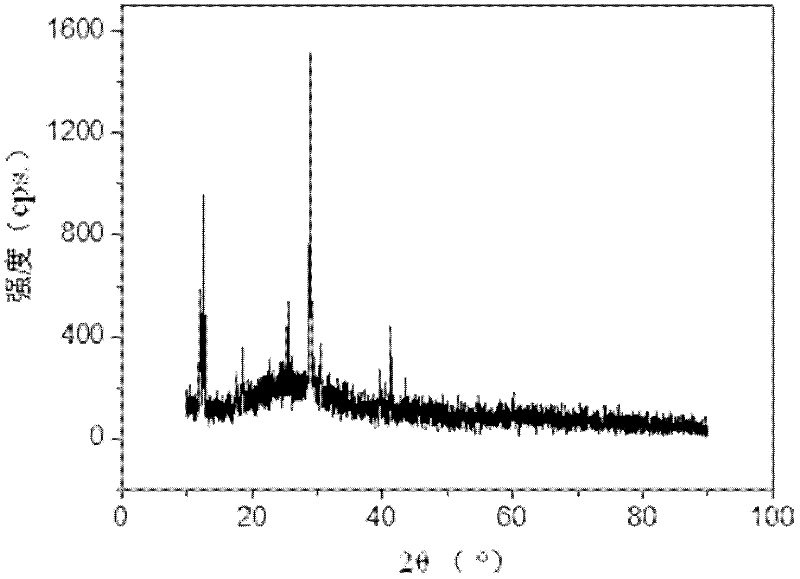

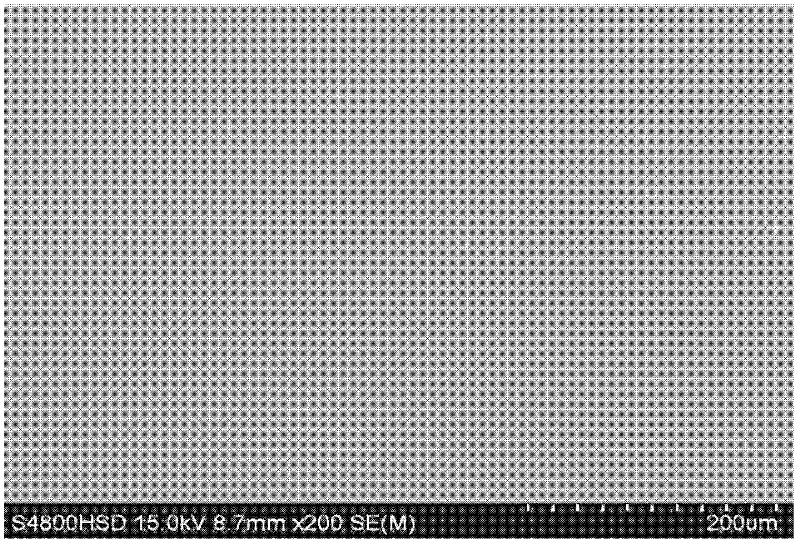

Self-assembly method for air-water interface vanadium oxide nano film

A nano-film and vanadium oxide technology, which is applied in the field of preparation of vanadium oxide nano-film, can solve the problems that the film is easy to crack, not easy to obtain, and the surface is not smooth, so as to achieve the effect of no crack, smooth surface and simple preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0008] Specific embodiment one: the self-assembly method of the air-water interface vanadium oxide nano-film of the present embodiment is carried out according to the following steps: one, be 1: 5~7 by the volume ratio of the ammoniacal liquor of 25% by water and mass fraction, water and The volume ratio of hydrogen peroxide is 1: 2~3 Weigh water, mass fraction is 25% ammoniacal liquor and hydrogen peroxide and mix uniformly, obtain alkaline lotion; The ratio is 1:3~4, weigh hydrogen peroxide and dilute sulfuric acid with a mass fraction of 15%~20%, and mix them evenly to obtain an acidic lotion; 3. Put the glass petri dish, glass slide and glass container in the first step to prepare ultrasonically oscillate in the alkaline lotion for 25min to 35min, then place it in the acidic lotion prepared in step 2 and oscillate ultrasonically for 25min to 35min, take it out, rinse it with distilled water, and set aside; 4. The concentration of sodium naphthalenesulfonate is 0.035mol / L~...

specific Embodiment approach 2

[0010] Specific embodiment two: the difference between this embodiment and specific embodiment one is that in step one, the volume ratio of water and mass fraction of 25% ammonia water is 1: 5.2~6.8, and the volume ratio of water and hydrogen peroxide is 1: 2.1~ 2.9 Weigh water, ammonia water and hydrogen peroxide with a mass fraction of 25% and mix them uniformly to obtain an alkaline washing solution. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0011] Specific embodiment three: the difference between this embodiment and specific embodiment one is that in step one, the volume ratio of water and mass fraction of 25% ammonia water is 1: 5.5, the volume ratio of water and hydrogen peroxide is 1: 2.5 to take water, Ammonia and hydrogen peroxide with a mass fraction of 25% are uniformly mixed to obtain an alkaline washing solution. Others are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com