Blumea riparia tablet and preparation process thereof

A cinnamon cinnamon tablet and a preparation process technology, which is applied in the direction of non-active ingredient medical preparations, medical preparations containing active ingredients, plant raw materials, etc., can solve the problem of low extraction rate of cinnamon cinnamon, long heating time, Problems such as large investment in equipment, to achieve the effect of improving bioavailability, simple preparation process, and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

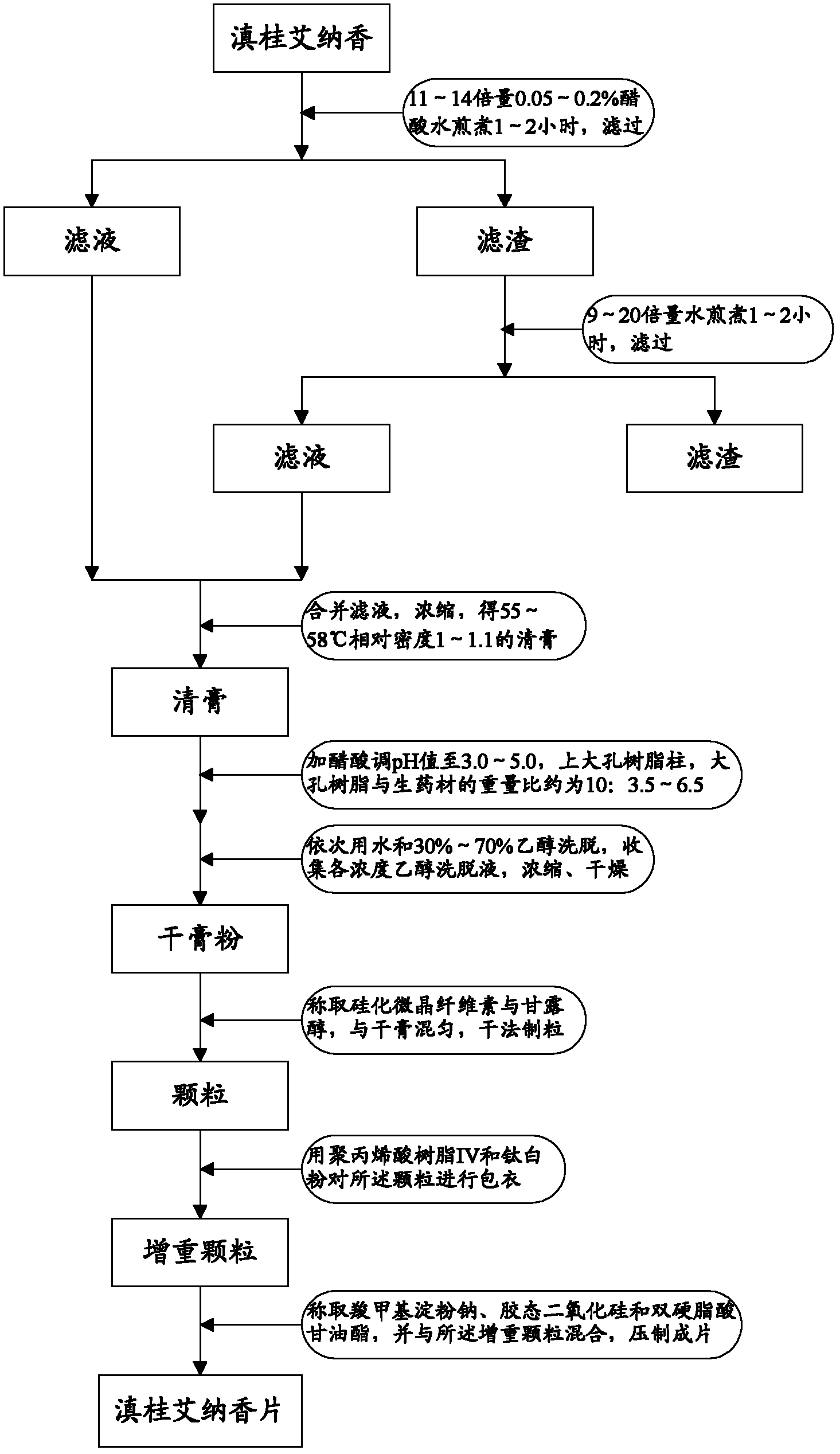

Method used

Image

Examples

Embodiment 1

[0028] Weigh 3500g of Diangui Ainaxiang, add 12 times the weight of 0.1% acetic acid water to decoct for 1.5 hours, filter, add 15 times the weight of water to the filter residue and decoct for 1.5 hours, filter, combine the two decoctions, and concentrate the filtrate To 60°C clear paste with a relative density of about 1.05, add acetic acid to adjust the pH value to 4.0, put it on a DA-201 macroporous resin column, the weight ratio of macroporous resin to clear paste is 10:3.7, and then use 1 times the amount of water in turn Elute with 3 times the amount of 30%, 55% and 80% ethanol at a speed of 4BV / h, collect and combine the ethanol eluents of various concentrations, concentrate, dry, control the moisture content to be less than 3%, and crush to obtain the extract of Artemisia argyi Dry cream powder. Take by weighing 70 grams of silicified microcrystalline cellulose, 10 grams of mannitol and mix evenly with the prepared dry paste powder of the extract of osmanthus osmanthu...

Embodiment 2

[0030] Weigh 3000g of Diangui Ainaxiang, add 11 times the weight of 0.05% acetic acid water to decoct for 2 hours, filter, add 20 times the weight of the filter residue to decoct for 1 hour, filter, combine the two decoctions, and concentrate the filtrate To 60°C clear paste with a relative density of about 1.05, add acetic acid to adjust the pH value to 3.0, put it on a DA-201 macroporous resin column, the weight ratio of macroporous resin to clear paste is 10:3.5, and then use 1 times the amount of water in turn Elute with 3 times the amount of 30%, 55% and 80% ethanol at a speed of 4BV / h, collect and combine the ethanol eluents of various concentrations, concentrate, dry, control the moisture content to be less than 3%, and crush to obtain the extract of Artemisia argyi Dry cream powder. Take by weighing 30 grams of silicified microcrystalline cellulose, 5 grams of mannitol and mix them evenly with the prepared dry paste powder of the osmanthus osmanthus extract, adjust the...

Embodiment 3

[0032] Weigh 3800g of Diangui Ainaxiang, add 14 times the weight of 0.2% acetic acid water to decoct for 1 hour, filter, add 9 times the weight of water to the filter residue and decoct for 2 hours, filter, combine the two decoctions, and concentrate the filtrate To 60°C clear paste with a relative density of about 1.05, add acetic acid to adjust the pH value to 5.0, put it on a DA-201 macroporous resin column, the weight ratio of macroporous resin to clear paste is 10:6.5, and then use 1 times the amount of water in turn Elute with 3 times the amount of 30%, 55% and 80% ethanol at a speed of 4BV / h, collect and combine the ethanol eluents of various concentrations, concentrate, dry, control the moisture content to be less than 3%, and crush to obtain the extract of Artemisia argyi Dry cream powder. Take by weighing 100 grams of silicified microcrystalline cellulose, 20 grams of mannitol and mix evenly with the prepared dry paste powder of the extract of osmanthus osmanthus, ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com