High-temperature resistant and erosion resistant rubber composition and preparation method thereof

A rubber composition and anti-ablation technology, applied in the field of polymer processing, can solve the problems of material loss of elasticity and flexibility, loss of sealing, etc., and achieve simple preparation and molding process, good elasticity and mechanical properties, and wide applicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

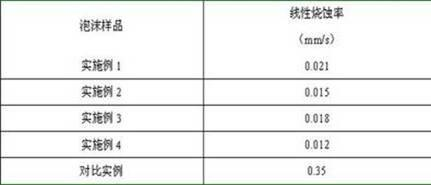

Examples

Embodiment 1

[0036] Example 1 : Add 100 parts of methyl vinyl silicone rubber, gas phase SiO 2 30 parts, 0.5 parts of platinum black, 10 parts of copper oxide, 5 parts of aluminum oxide, 15 parts of boron nitride ceramic fiber, 50 parts of wollastonite, and knead until uniformly mixed; after natural aging at room temperature for 8 hours, put them in a double-roll mill Continue mixing and add 5 parts of α-type silicon carbide whiskers and 1.5 parts of bis(2,4-dichlorobenzoyl peroxide) successively. After 20 minutes of kneading, the sheet is produced, and vulcanized in a flat vulcanizing machine at 200°C for 25 minutes to form .

Embodiment 2

[0037] Example 2 : 50 parts of methyl vinyl silicone rubber, 50 parts of methyl phenyl vinyl silicone rubber, precipitation SiO 2 20 parts, 0.8 parts of chloroplatinic acid, 5 parts of magnesium oxide, 20 parts of iron oxide, silicon nitride (Si 3 N 4) 5 parts of ceramic fiber and 80 parts of mica were kneaded until evenly mixed; after natural aging at room temperature for 8 hours, the kneading was continued in a double-roll mill and 15 parts of β-type silicon carbide whiskers, 0.8 dicumyl peroxide After 30 minutes of kneading, the sheets are released, and they are vulcanized in a flat vulcanizing machine at 200°C for 30 minutes.

Embodiment 3

[0038] Example 3: Add 100 parts of dimethyl silicone rubber, gas phase SiO 2 30 parts, 0.05 parts of chloroplatinic acid organosiloxane complex, 15 parts of zinc oxide, 25 parts of zirconia, 25 parts of SiBN ceramic fiber, 30 parts of quartz powder, 30 parts of diatomaceous earth, knead until uniformly mixed; After aging for 8 hours, continue mixing in a double-roller mill and add 1 part of silicon carbide whiskers and 2 parts of di-tert-butane peroxide in sequence. After 30 minutes of kneading, the sheet is released, and vulcanized in a flat vulcanizer at 180 ° C for 30 Shaped in minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com