Vinylidene fluoride resin porous membrane, manufacturing method therefor, and method for manufacturing filtrate water

一种二氟乙烯、制造方法的技术,应用在多孔膜领域,能够解决持续性不足、膜强度或耐化学性降低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

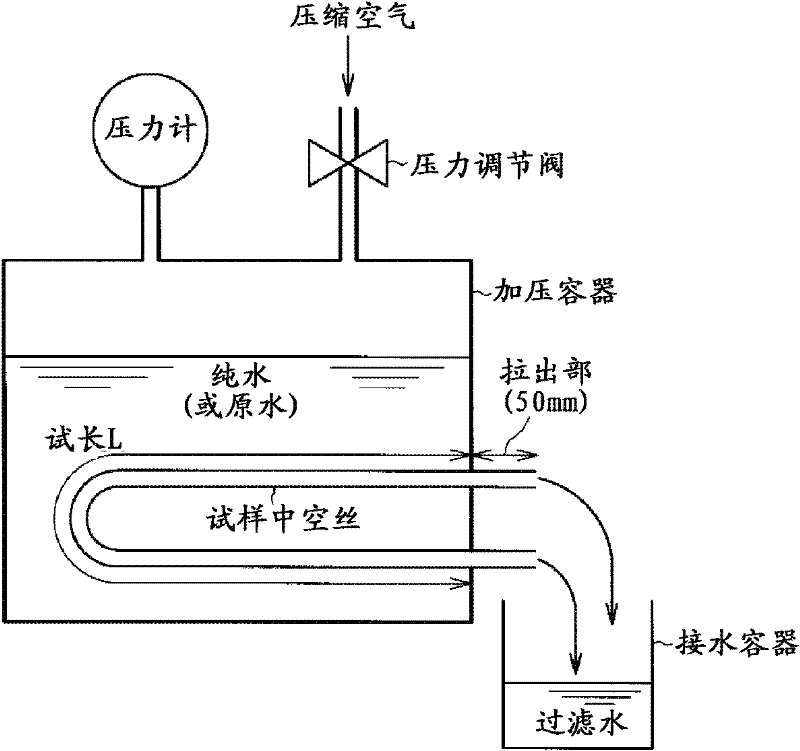

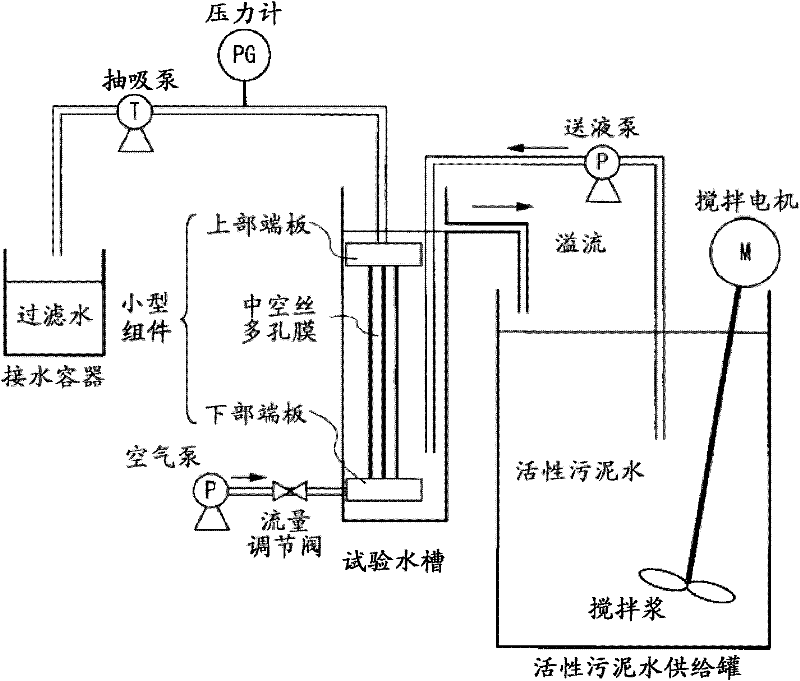

Method used

Image

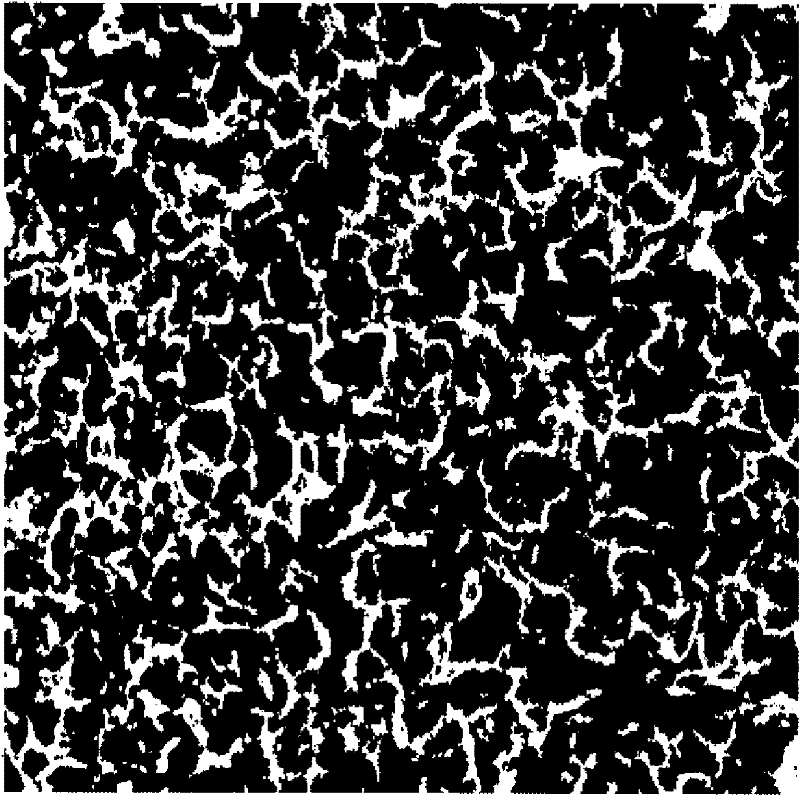

Examples

Embodiment 1

[0147] Using a Henschel mixer, the weight average molecular weight (Mw) was 4.1×10 5 The substrate is polyvinyl difluoride (PVDF-I) (powder) and Mw is 9.7×10 5 Polyvinylidene fluoride (PVDF-II) (powder) for modifying the crystallization characteristics of the 1,1-difluoroethylene (PVDF-II) (powder) is mixed according to the ratio of 75% by weight and 25% by weight respectively, and the obtained Mw is 5.4×10 5 PVDF mixture (mixture A; crystallization temperature Tc after film formation = 150.4° C.).

[0148] As the plasticizer, adipic acid-based polyester-based plasticizer (polyester of adipic acid and 1,2-butanediol terminated with isononyl alcohol; "D623N" manufactured by Geeyi Plus Co., Ltd., number The average molecular weight is about 1800, and the measured viscosity at 25°C measured according to JIS K7117-2 (cone-plate rotary viscometer) is 3000mPa·s) and diisononyl adipate as a monomeric ester plasticizer Esters ("DINA" manufactured by Jiei Plus Co., Ltd.) were stirred...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com