Electrochemical preparation process of Cu2ZnSnS4 film

A preparation process and electrochemical technology, applied in metal material coating process, electrolytic inorganic material coating, ion implantation coating, etc., can solve the problems of complex process, deviation of components from ideal chemical ratio, lack of deep understanding of microscopic physical mechanism, etc. , to achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

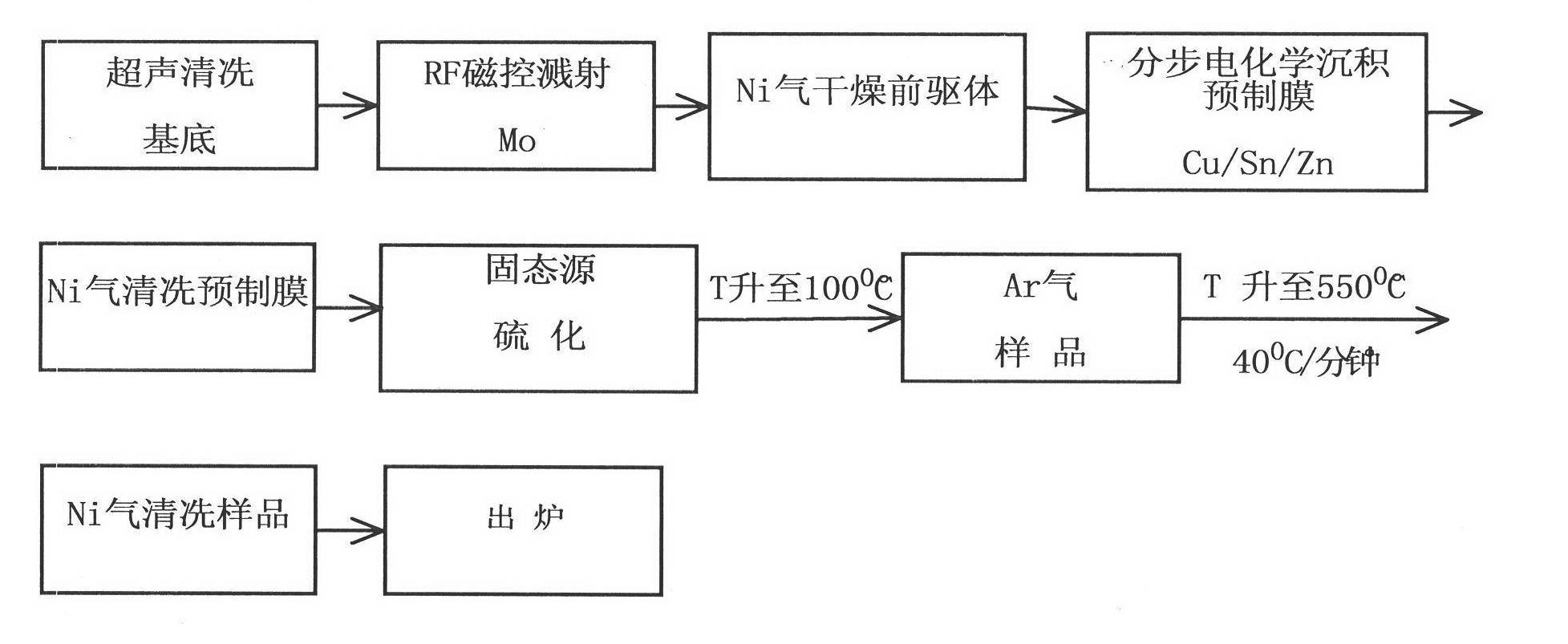

[0012] (1) Soda-lime glass substrate (10mm×10mm) was ultrasonically cleaned with detergent, distilled water, isopropanone and ethanol for 10 minutes, and then dried with nitrogen gas (flow rate 0.1m3 / h) for 5 minutes;

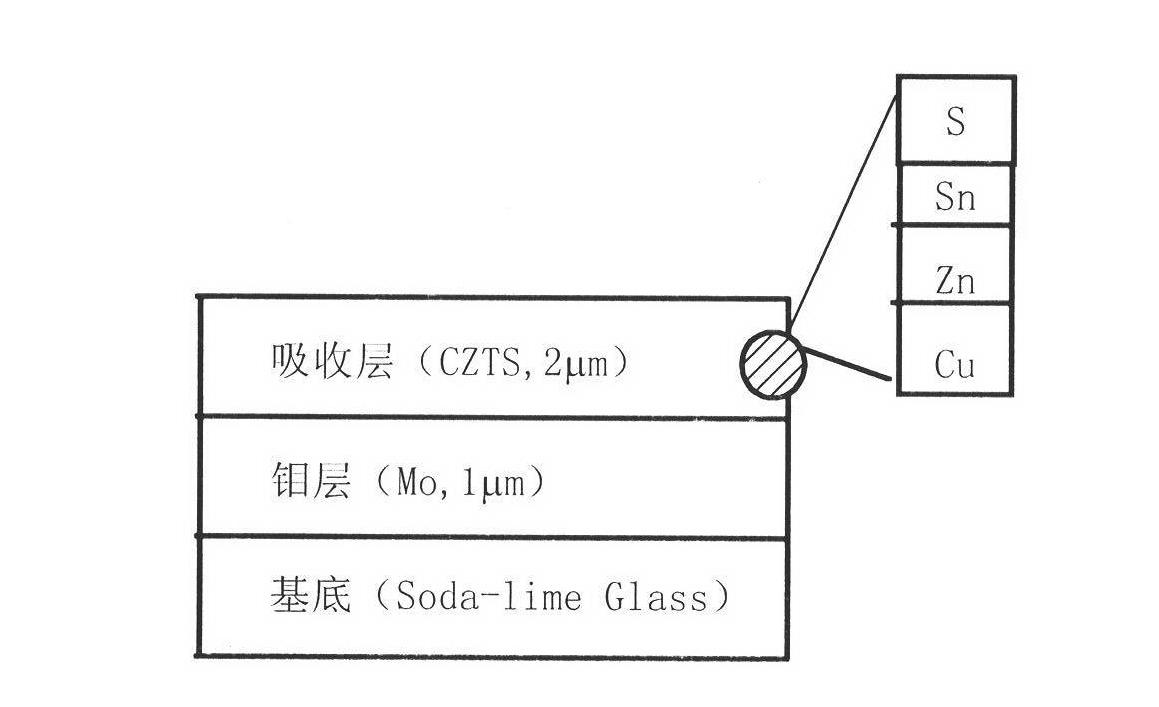

[0013] (2) Mask the edge of the soda-lime glass substrate with polytetrafluoroethylene (PTFE), and deposit a molybdenum layer (precursor) with a thickness of 1 μm on the substrate by radio frequency (RF) magnetron sputtering;

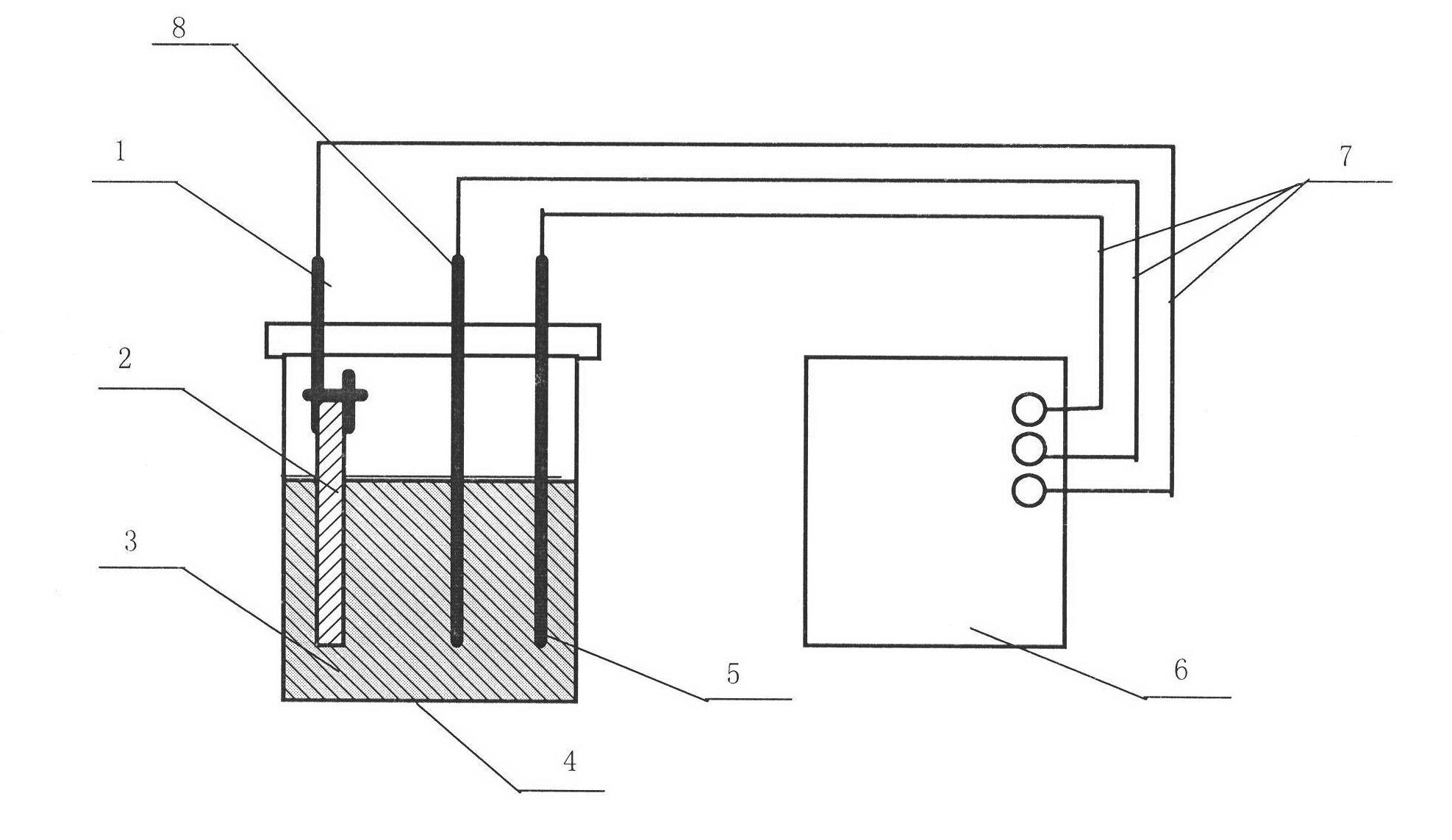

[0014] (3) prepare three kinds of electrolytic solutions of A, B and C respectively with deionized water and metal salt (purity is 99.99wt%): A electrolytic solution is to contain 1.5 moles of sodium hydroxide (NaOH), 50 millimoles of copper chloride ( CuCl2) and 0.1 mole sorbitol (sorbitol) alkaline solution; B electrolyte is a solution containing 0.15 mole zinc chloride (ZnCl2) and buffered by hydrogen ions with a pH value of 3; C electrolyte is a solution containing 2.25 mole hydroxide Sodium (NaOH), an alkaline solution of 55 mmoles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com