Foamed ceramic thermal insulation plate and manufacture method thereof

A foamed ceramic and thermal insulation board technology, which is applied to ceramic products, other household appliances, household appliances, etc., can solve the problems of large shrinkage of thermal insulation slurry, limited durability, empty drum, etc., and achieves close linear expansion coefficient and aging resistance. The effect of low performance and thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

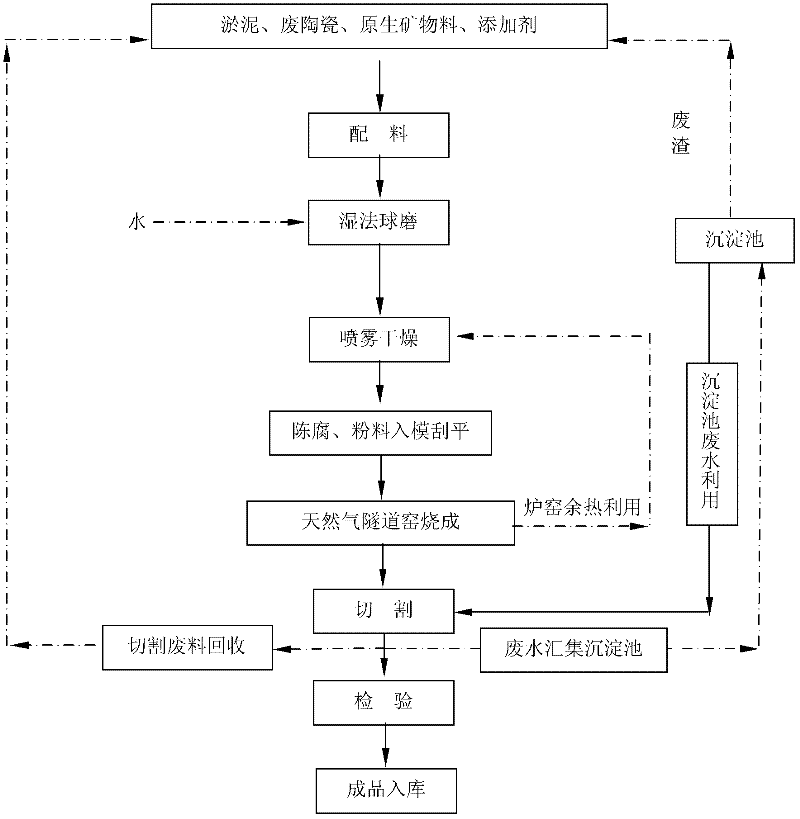

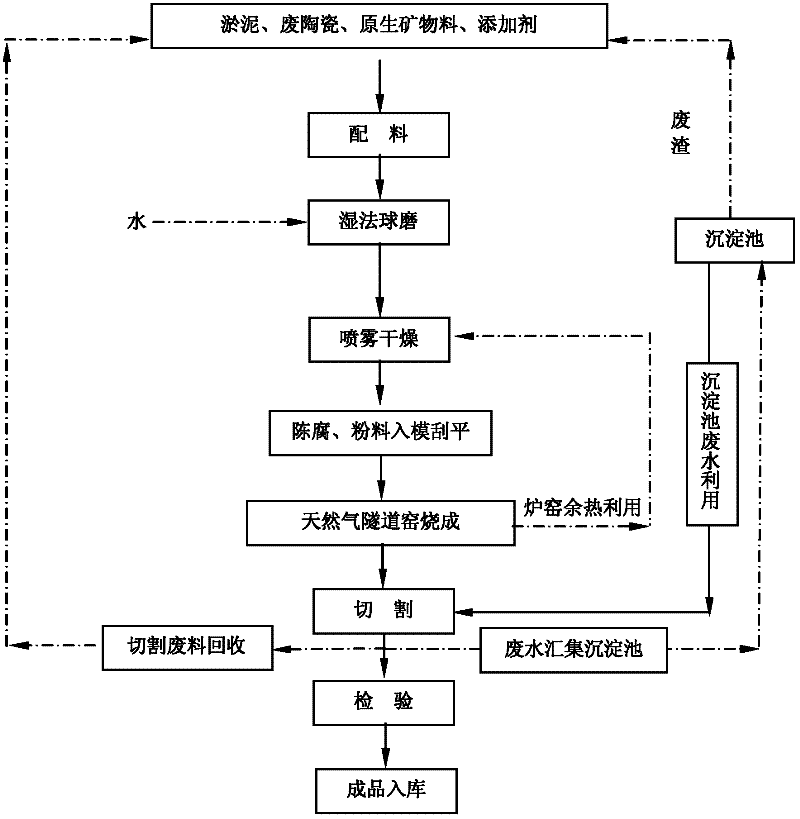

Method used

Image

Examples

Embodiment 1

[0036] Example 1: The foamed ceramic insulation board in this example is made from the following components: 40 parts of silt, 10 parts of dikai stone, 20 parts of kaolin, 15 parts of feldspar, 2 parts of calcite, 10 parts of dolomite, 0.5 part of modifier, 1 part of stabilizer, 1.5 parts of SiC, in parts by weight.

[0037] Among the above components, the silt is directly obtained from Taihu Lake, and the dikaiite, kaolin, feldspar, calcite, dolomite, modifiers and stabilizers are all commercially available products.

[0038] The preparation method comprises the following steps:

[0039] (1) After mixing all components, crush and wet ball mill;

[0040] (2) spray drying;

[0041] (3) Stale, put the stale powder into the mold and scrape it flat, and put it into the natural gas tunnel kiln;

[0042] (4) After being fired in a high-temperature continuous kiln at 1150-1250 ° C, a lightweight foamed ceramic insulation material with closed pores evenly densely formed is formed...

Embodiment 2~5

[0047] Examples 2-5: A foamed ceramic insulation board, the preparation method of which is the same as that of Example 1, and the components and weight parts used in each example are shown in Table 2.

[0048] Components and parts by weight used in Table 2 Examples 2 to 5

[0049] Example 2 Example 3 Example 4 Example 5 silt 35 45 50 65 Dickey 4 5 10 7 Kaolin 10 10 13 20 Feldspar 6 15 6 5 Calcite 2 5 4 5 dolomite 10 5 5 5 modifier 0.1 0.5 0.5 0.1 stabilizer 0.5 1 0.5 1.2 SiC 0.4 0.5 1.5 0.8 Ceramic insulation board waste 42 20 10 0

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com