Fe molecular sieve catalyst for purifying NOx in acrylonitrile oxidization tail gas and preparation method of Fe molecular sieve catalyst

A molecular sieve and catalyst technology, which is applied in the field of catalytic purification of tail gas of acrylonitrile plant, achieves the effects of simple preparation process, good repeatability and excellent NOx conversion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

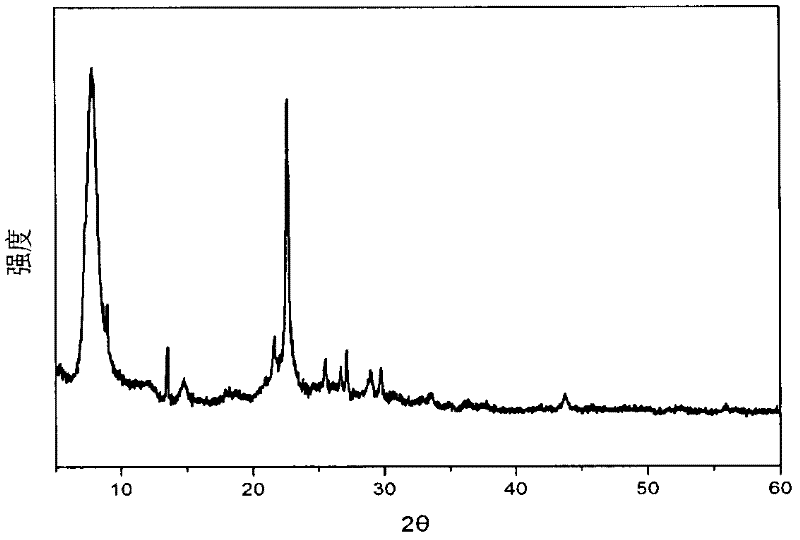

Image

Examples

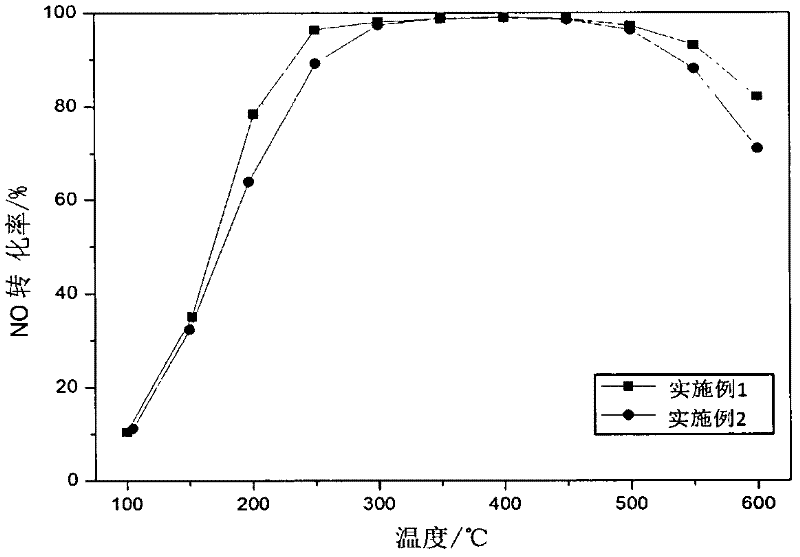

Embodiment 1

[0020] Commercial 10g sodium molecular sieve Na-β molecular sieve powder (Zibo Qichuang Chemical Technology Development Co., Ltd.) and 100mL27% NH 4 NO 3 The solution was uniformly mixed, ion-exchanged at 80°C for 4 hours, filtered and washed, dried at 120°C for 12 hours, and calcined at 550°C for 4 hours to obtain hydrogen molecular sieve H-β. 10g H-β with 150mL 0.1M FeCl 3 The solutions were mixed, exchanged for metal ions at 70°C for 8h, filtered and washed, and dried at 120°C for 8h. The dried sample was calcined at 550° C. for 4 hours at a heating rate of 10° C. / min to obtain the Fe-β catalyst sample by the exchange method of Example 1. Its Fe content is 0.8-1% as tested by ICP. The obtained catalyst Fe-β0.5g contains 5% O at 500°C 2 Pre-oxidize in a nitrogen atmosphere for 30 minutes, after cooling down to room temperature, the temperature is programmed at a rate of 10°C / min, and a mixed atmosphere with a total flow rate of 1L / min is introduced, which contains 500ppm...

Embodiment 2

[0022] Commercial 10g sodium molecular sieve Na-β molecular sieve raw powder (Zibo Qichuang Chemical Technology Development Co., Ltd.) and 100mL 27% NH 4 NO 3 The solution was uniformly mixed, ion-exchanged at 80°C for 4 hours, filtered and washed, dried at 120°C for 12 hours, and calcined at 550°C for 4 hours to obtain hydrogen molecular sieve H-β. Then test its water absorption: add water dropwise to a constant mass molecular sieve, grind and stir continuously, dropwise add until obvious liquid appears on the surface of the powder, absorb the excess water with filter paper, and weigh it. Calculate the drop solution volume according to the saturated water absorption rate, add 300mL 0.05M FeCl dropwise to 10g H-β molecular sieve 3 The solution was ground for 30 minutes, aged for 4 hours at room temperature and then dried at 150°C for 4 hours. The dried sample was calcined at 550° C. for 4 hours at a heating rate of 10° C. / min to obtain the impregnated Fe-β catalyst sample of...

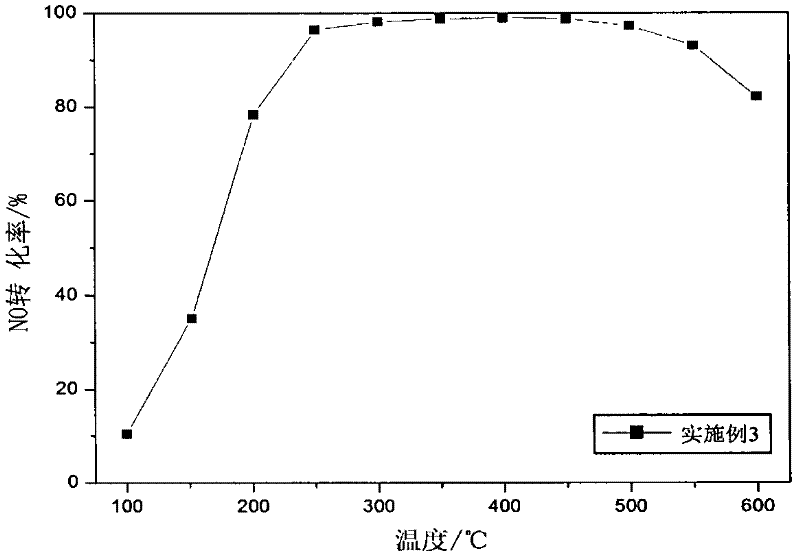

Embodiment 3

[0024] Commercial 10g sodium molecular sieve Na-ZSM5 molecular sieve raw powder (Shanghai Zhuoyue Chemical Industry) and 100mL 27% NH 4 NO 3 Mix the solution evenly, ion exchange at 80°C for 4h, filter and wash, dry at 120°C for 12h, and roast at 550°C for 4h to obtain hydrogen molecular sieve H-ZSM5. 10g H-ZSM5 and 200mL of 0.1M FeCl 3 The solutions were mixed, exchanged for metal ions at 70°C for 8h, filtered and washed, and dried at 120°C for 8h. The dried sample was calcined at 550° C. for 4 hours at a heating rate of 10° C. / min to obtain the Fe-ZSM5 catalyst sample by the exchange method in Example 3. Its Fe content is 1-1.2% as tested by ICP. The prepared catalyst Fe-ZSM50.5g contains 5%O at 500°C 2 Pre-oxidize in a nitrogen atmosphere for 30 minutes, after cooling down to room temperature, the temperature is programmed at a rate of 10°C / min, and a mixed atmosphere with a total flow rate of 1L / min is introduced, which contains 500ppm NO, 500ppm NH 3 , 5%O 2 , to det...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com