Mutant nitrile hydratase

A nitrile hydratase and amino acid technology, applied in the directions of lyase, biochemical equipment and methods, applications, etc., can solve the problems of poor heat resistance of enzyme-producing cells, fluctuations in hydration temperature, and insufficient supply of cold energy for temperature control, and achieve good Prospects for industrial application, product tolerance improvement, effect of ultrasonic tolerance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

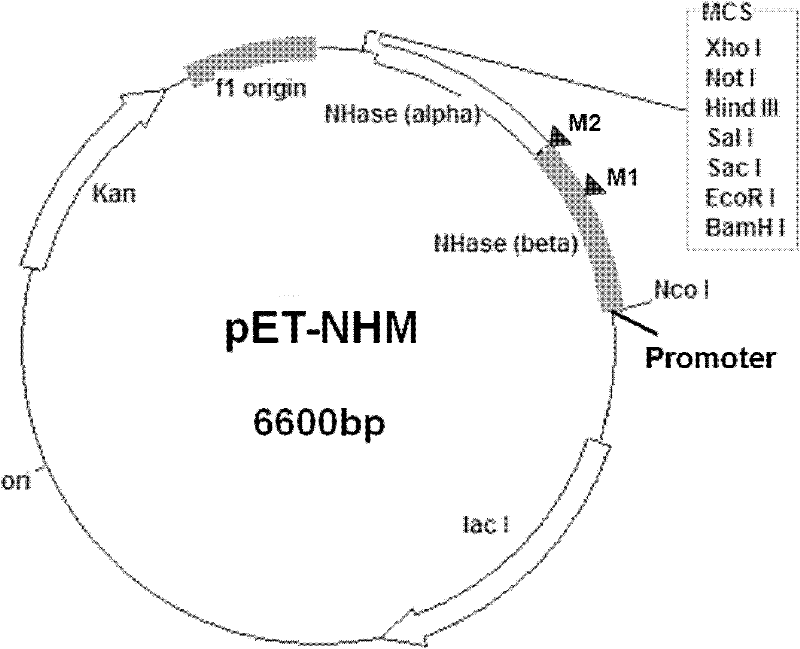

[0022] Embodiment 1 Improved nitrile hydratase NHM gene mutation and its transformant construction

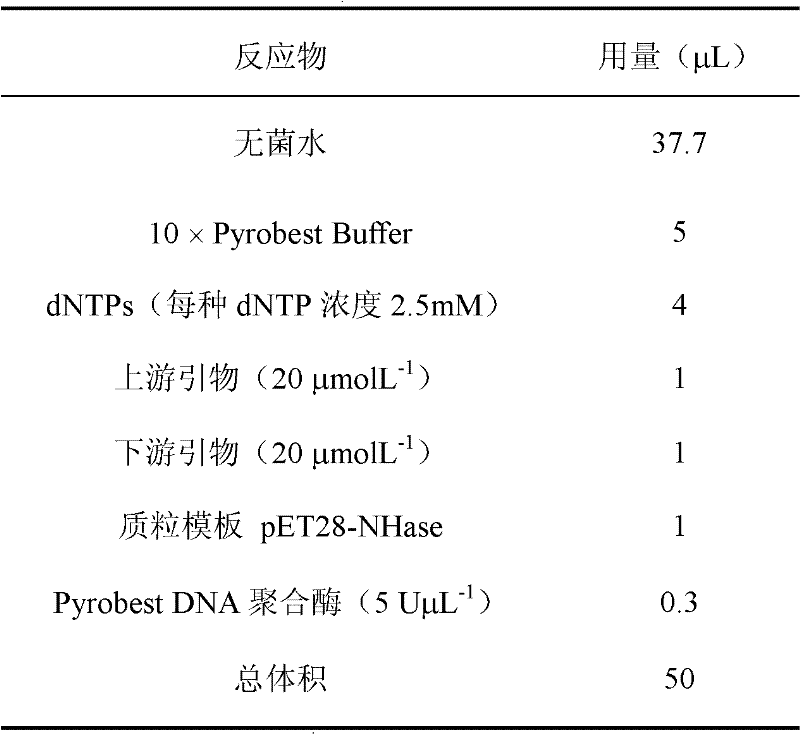

[0023] (1) Referring to the method described in Tsinghua University patent (Chinese invention patent application number: 200910076710.1), using upstream primer: PNH-F: TTTAAGAAGGAGATATACCATGGATGGAT and downstream primer: PNH-R: CCGCAAGCTTTCATACGATCACTTC, routinely amplifies Rhodococcus ruber TH ( The nitrile hydratase gene (sequence shown in SEQ ID NO: 3) in the General Microbiology Center of China Committee for Microorganism Culture Collection (CGMCC No.2380) was subjected to NcoI / BamHI double enzyme digestion reaction at 37°C for 4h. Purify the resulting digested product with a PCR product recovery kit (Takara Company), and then use T4 DNA ligase (Promega Company) to perform a ligation reaction with the plasmid vector pET-28a (Novagen Company) at 4°C for 16 h; then transform the ligation reaction product Competent cells of host bacterium E.coli BL21 (DE3) (Tiangen Biochemical...

Embodiment 2

[0027] Embodiment 2 The present invention improves the expression of nitrile hydratase in transformants

[0028] The strain E.coli BL21(DE3) / pET-NHM obtained in Example 1 for inducible expression of the improved nitrile hydratase of the present invention due to SEQ ID NO: 5 was cultured in shake flasks. First inoculate a single colony in LB liquid medium containing 50mg / L kanamycin (composition: 50ml / 300ml shake flask, peptone 10g / L, yeast powder 5g / L, sodium chloride 10g / L, pH 7.0) , 37° C., 200 rpm for 12 hours, and make a seed bottle.

[0029]According to 1% inoculum amount, transfer from seed bottle to LB liquid medium (50ml) containing 50mg / L kanamycin and cultivate for 2.5h. Add 2% 0.5mol / L lactose, 0.2% 0.2mol / L CoCl 2 Acts as an inducer to induce nitrile hydratase expression. After culturing at 28°C for 8 hours, the cells were harvested for enzyme activity assay.

[0030] Enzyme activity was determined by gas chromatography with acrylonitrile as substrate. Take 3....

Embodiment 3

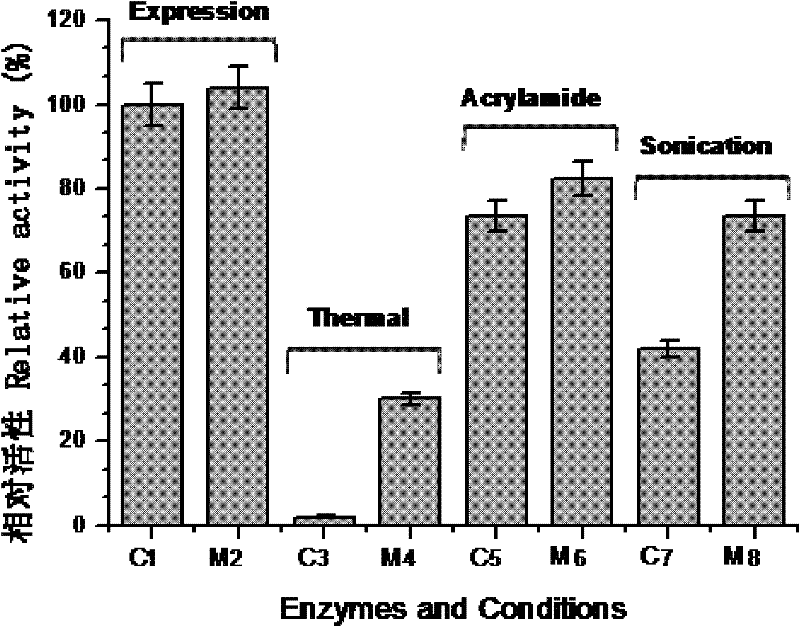

[0032] Embodiment 3 The stress resistance evaluation of the improved nitrile hydratase of the present invention

[0033] The 50ml recombinant bacterium E.coli BL21 (DE3) / pET-NHM cell (expressing improved nitrile hydratase) of embodiment 2 harvest and control bacterial strain E.coli BL21 (DE3) / pET-Nhase cell (expressing unmutated original nitrile hydratase) Enzyme) was centrifuged and washed once with an equal volume of sterile water, and then resuspended in an equal volume of 50mM PBS buffer at pH 7.0 for further use.

[0034] Take 5ml of the recombinant cells resuspended in PBS buffer and place them in a water bath at 42°C for 12h. The residual activity of the improved nitrile hydratase and the original nitrile hydratase were measured in parallel, and the results showed that the residual activity of the improved nitrile hydratase was 30%, while that of the unmutated nitrile hydratase was only 2%. The thermostability of the improved nitrile hydratase was significantly improve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com