Minocycline hydrochloride nano calcium carbonate preparation and preparation method thereof

A technology of minocycline hydrochloride and nano-calcium carbonate, applied in the field of medicine, can solve the problems of slow excretion, potential safety hazards, side effects of nano-cycline hydrochloride, etc., and achieves the effects of high drug loading rate, improved stability, and reduced toxic and side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

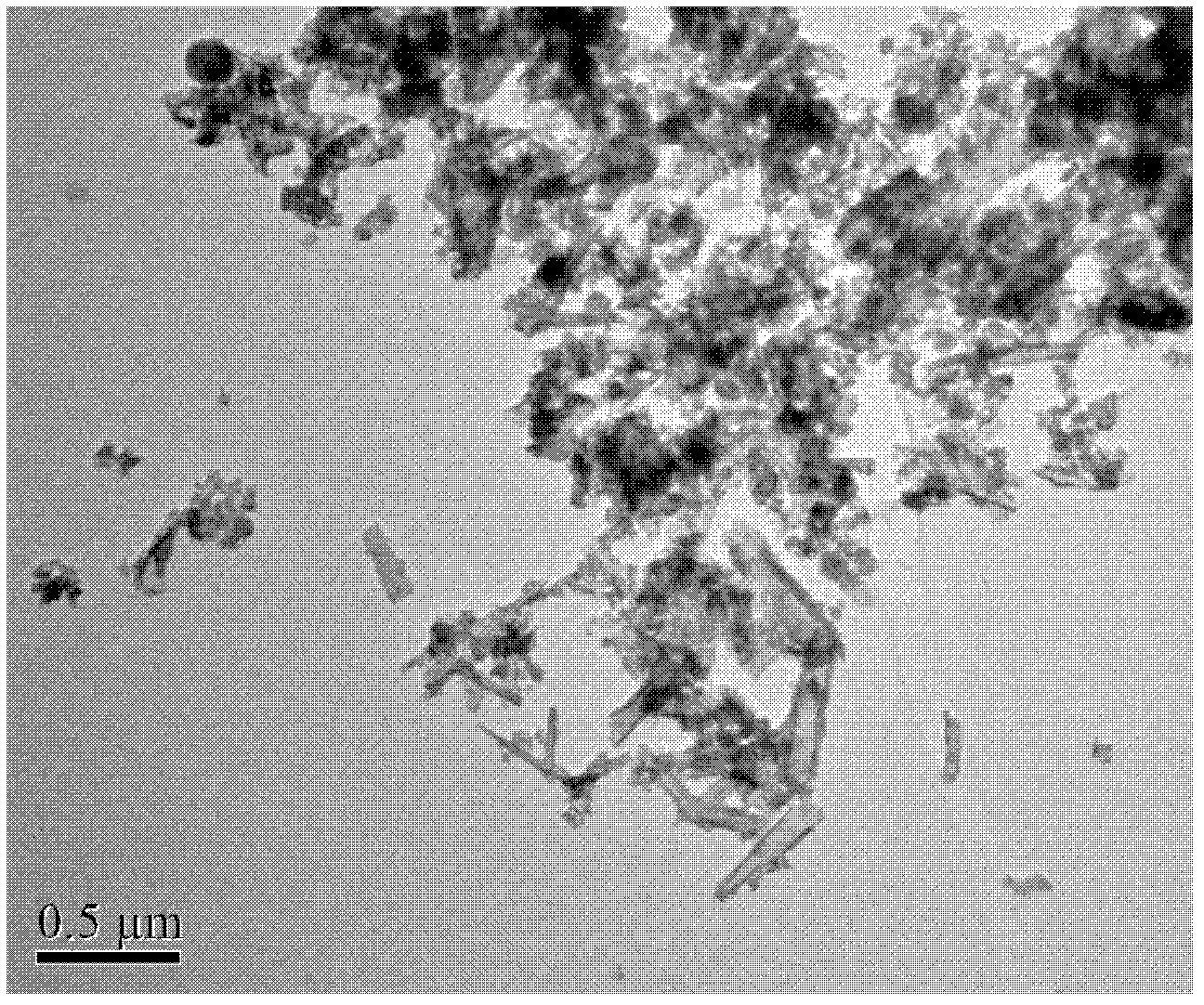

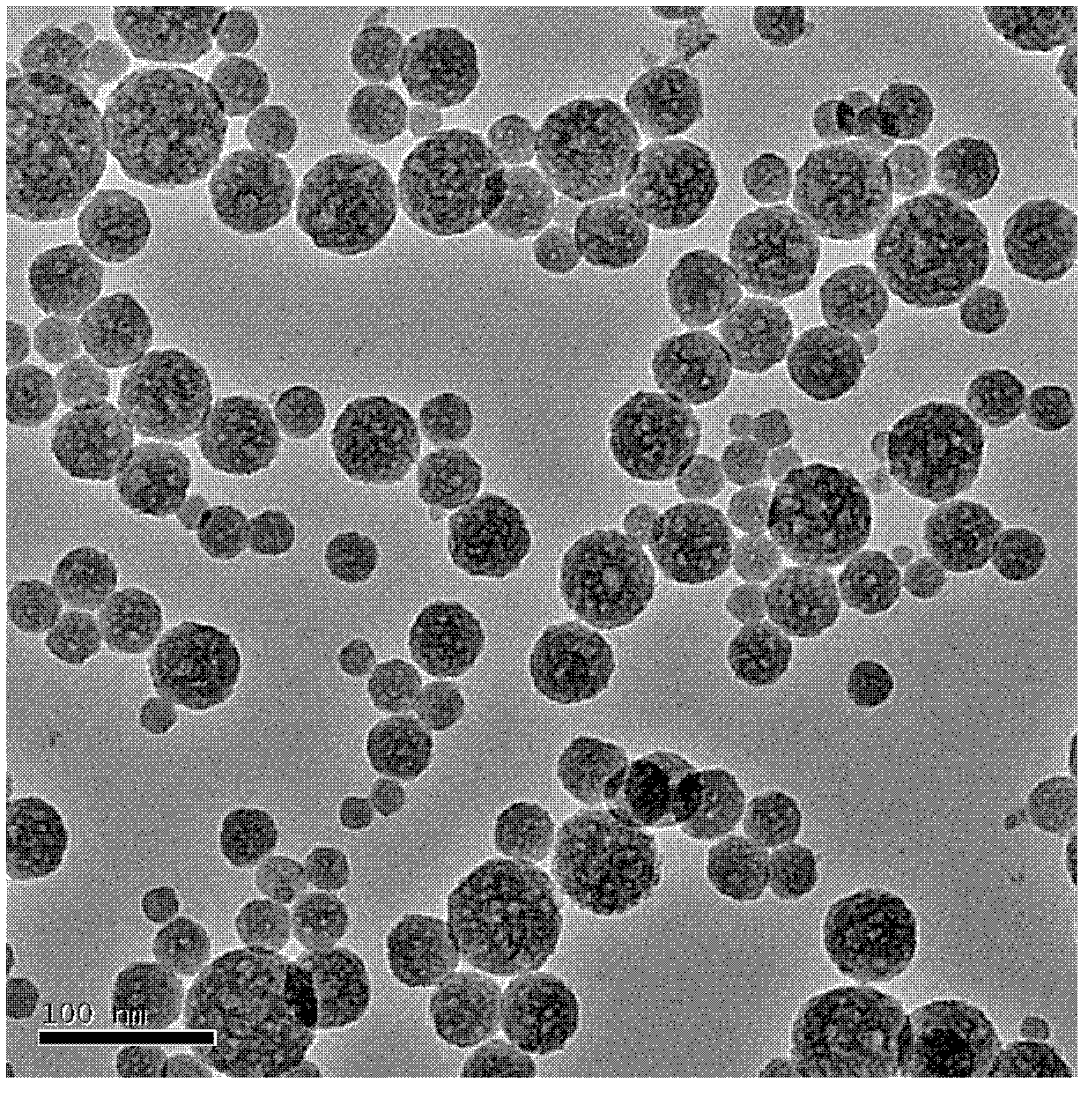

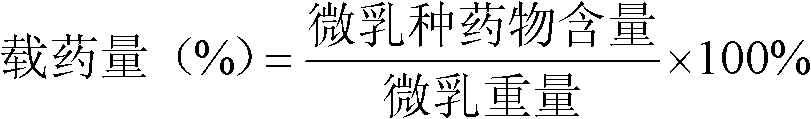

Method used

Image

Examples

Embodiment 1

[0024] 1) Prepare calcium chloride and ammonium carbonate aqueous solutions of 10 millimoles per liter respectively for subsequent use.

[0025] 2) Take 0.1 ml of calcium chloride and add the corresponding epiminocycline hydrochloride (the molar ratio of calcium chloride to epiminocycline hydrochloride is 5:1), after ultrasonic dispersion is uniform, the calcium chloride aqueous solution containing the drug Add it to 10 ml of organic phase, and ultrasonically homogenize to form A emulsion, which is set aside.

[0026] 3) Take the same volume of ammonium carbonate aqueous solution as the calcium chloride aqueous solution containing the drug in step 2, add it to 5 ml of organic phase, and ultrasonically homogenize to form B emulsion for later use.

[0027] 4) Under the condition of magnetic stirring, slowly add emulsion B into emulsion A, and stir for 2 hours after adding.

[0028] 5) Add the mixed solution in step 4 to ethanol to break the emulsion, then centrifuge and wash, a...

Embodiment 2

[0031] 1) Prepare calcium chloride and ammonium carbonate aqueous solutions of 100 millimoles per liter respectively for subsequent use.

[0032] 2) Take 0.2 ml of calcium chloride and add the corresponding epiminocycline hydrochloride (the molar ratio of calcium chloride to epiminocycline hydrochloride is 4:1), after ultrasonic dispersion is uniform, the calcium chloride aqueous solution containing the drug Add it to 15 ml of organic phase, and ultrasonically homogenize to form A emulsion, which is set aside.

[0033] 3) Take the same volume of ammonium carbonate aqueous solution as the calcium chloride aqueous solution containing the drug in step 2, add it to 15 ml of organic phase, and ultrasonically homogenize to form B emulsion, which is set aside.

[0034] 4) Under the condition of magnetic stirring, slowly add emulsion B into emulsion A, and stir for 1.5 hours after adding.

[0035] 5) Add the mixed solution in step 4 to ethanol to break the emulsion, then centrifuge a...

Embodiment 3

[0037] 1) Prepare 300 millimoles per liter of calcium chloride and ammonium carbonate aqueous solution respectively for subsequent use.

[0038] 2) Take 0.3 ml of calcium chloride and add the corresponding epiminocycline hydrochloride (the molar ratio of calcium chloride to epiminocycline hydrochloride is 3:1), after ultrasonic dispersion is uniform, the calcium chloride aqueous solution containing the drug Add it to 20 ml of organic phase, and ultrasonically homogenize to form A emulsion, which is set aside.

[0039] 3) Take the ammonium carbonate aqueous solution of the same volume as the calcium chloride aqueous solution containing the drug in step 2, add it to 20 ml of organic phase, and ultrasonically homogenize to form B emulsion for later use.

[0040] 4) Under the condition of magnetic stirring, slowly add B emulsion into A emulsion, and stir for 1 hour after adding.

[0041] 5) Add the mixed solution in step 4 to ethanol to break the emulsion, then centrifuge and was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com