Method for plating films of multi-arc ion plating

A multi-arc ion plating and plasma technology, which is applied in the field of physical vapor deposition (PVD), can solve the problems of reducing the friction and wear resistance and high temperature oxidation resistance of coatings, increasing the consumption of target sources, and complicated devices, etc. The effects of large particle pollution, improved cleaning quality, and increased ambient temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

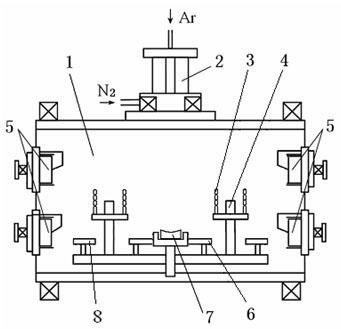

[0030] Implementation using as figure 1 The coating equipment shown has the function of multi-arc ion plating and hollow cathode ion plating. It can use the function of multi-arc ion plating or hollow cathode ion plating alone. It can also use multi-arc ion plating and ion plating at the same time. Composite ion plating function of hollow cathode ion plating; this equipment can set hollow cathode device 2 in vacuum chamber 1 while multi-arc source 5 emits plasma, and use lanthanum boride (LaB 6 ) materials to emit plasma electron beams to the anode target 7 (titanium target) and the auxiliary anode 6 and auxiliary anode 8 located in the center of the vacuum chamber 1 below; the auxiliary anode 6 surrounds the anode target 7 to make the plasma The bulk electron beam and the plasma emitted by the multi-arc source 5 perform ideal intersecting motion.

[0031] Plating (50wt%Ti, 50wt%Al)N coating is carried out in four steps.

[0032] 1) Place sample 3 in figure 1 The hollow cat...

Embodiment 2

[0040] Implementation using as figure 1In the coating equipment shown, the (70wt%Ti, 30wt%Al)N coating is plated in four steps.

[0041] 1) Place sample 3 in figure 1 The hollow cathode shown and the workpiece frame 4 in the vacuum chamber 1 of the multi-arc ion composite coating machine are vacuumed to 6.0×10 -3 Pa;

[0042] 2) Turn on the hollow cathode electron gun 2 and form a circuit with the auxiliary anode 6 and the workpiece holder 4, heat the sample 3 and the workpiece holder 4 to 350°C, and clean the surface of the sample 3 by ion sputtering;

[0043] 3) Turn on the hollow cathode electron gun 2 and form a circuit with the anode target 7 and the auxiliary anode 6 to prepare the TiN transition layer;

[0044] 4) Turn on the multi-arc source 5, turn on the hollow cathode electron gun 2 and form a circuit with the auxiliary anode 8, and prepare the (70wt%Ti, 30wt%Al)N coating.

[0045] Plating is carried out as shown in Table 2 according to the process parameters wi...

Embodiment 3

[0049] Implementation using as figure 1 The coating equipment shown is still plated (70wt%Ti, 30wt%Al) N coating in four steps, wherein the first three steps are the same as in Example 2, and the fourth step adopts a smaller hollow cathode current value and reduces the pulse Bias voltage amplitude, its process parameter table is shown in Table 3.

[0050]

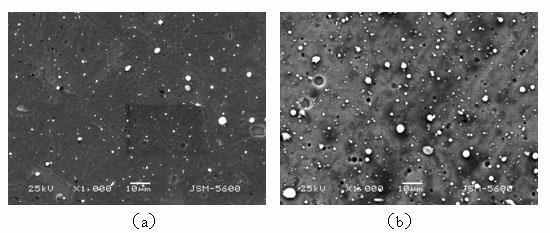

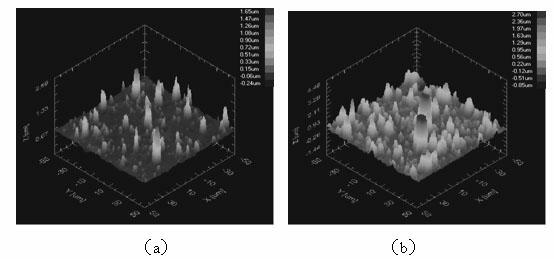

[0051] The (70wt%Ti, 30wt%Al) N coating that is plated by the above-mentioned plating method and the (70wt%Ti, 30wt%Al) N coating that is not plated by the multi-arc ion plating of the method of the present invention are subjected to surface laser Comparing the profiles, it can still be clearly seen that the (70wt%Ti, 30wt%Al)N coatings plated with the present invention have lower but equivalent number of protrusions on the surface. It shows that under this parameter of the present invention, the coating quality can still be obviously improved. Measure and compare the coating cross-sectional thickness with scanning ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com