Copper indium diselenide solar cell and production method thereof

A technology of solar cells and copper indium selenide, which is applied in the manufacture of circuits, electrical components, and final products, can solve problems such as uneven composition and crystal phase, difficult control of ingredients, and high manufacturing costs, so as to improve photoelectric conversion efficiency and improve composition Effects that are easy to control and low in production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The implementation of the present invention will be described in more detail below with reference to the drawings and component symbols, so that those skilled in the art can implement it after reading this specification.

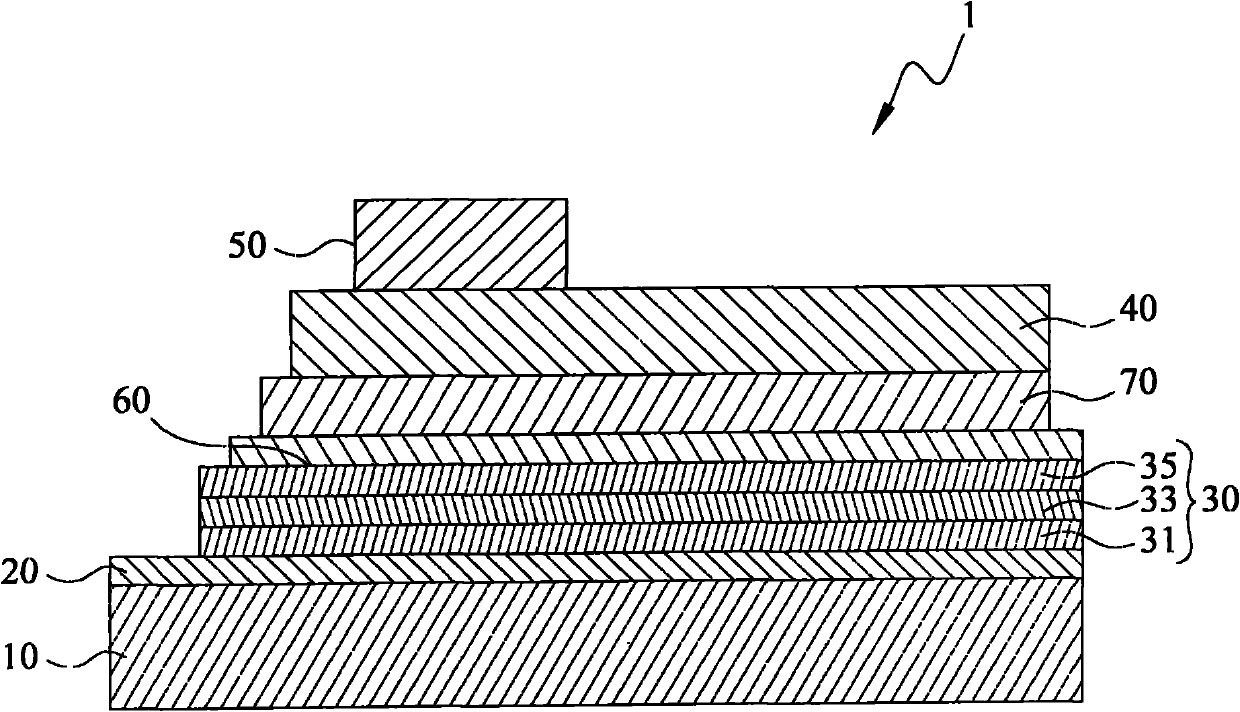

[0032] refer to figure 1 , Schematic diagram of the structure of the copper indium selenide solar cell of the present invention. Such as figure 1 As shown, the CISe solar cell 1 of the present invention includes a substrate 10 , a back metal electrode 20 , a light absorbing layer 30 , a transparent conductive layer 40 and a contact electrode layer 50 . The substrate 10 can be silicon wafer, glass, acrylic, rigid polymer substrate or flexible polymer substrate. The back metal electrode 20 is formed on the substrate 10 and is formed of a highly reflective metal material, preferably molybdenum (Mo). The light-absorbing layer 30 is formed on the back metal electrode 20 and includes a plurality of light-absorbing films, such as figure 1 The first light...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com