Preparation method for one-step synthesis of high-rate-performance carbon-coated lithium iron phosphate cathode material by in-situ hydrothermal carbonization

A carbon-coated lithium iron phosphate, in-situ hydrothermal technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problem of poor consistency and stability of electrochemical performance, hindering the development of lithium iron phosphate power batteries, and long calcination time. and other problems, to avoid side reactions, suitable for large-scale industrial production, and the process control parameters are mild and easy to control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

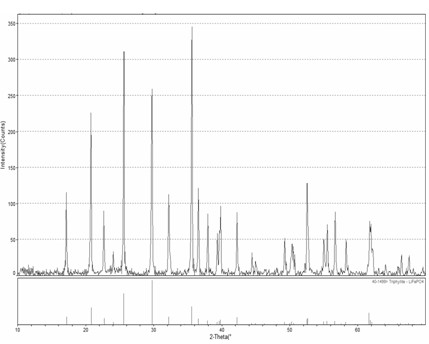

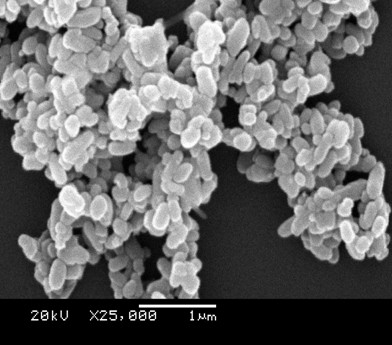

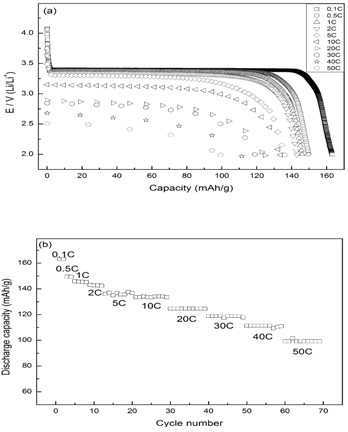

Embodiment 1

[0049] Prepare lithium hydroxide solution (1.5 mol / L) and ferrous sulfate solution (0.5 mol / L); under stirring conditions, mix lithium hydroxide, ferrous sulfate, and phosphoric acid solution evenly, add 1.5 g of glucose, and control the pH of the solution to 6-7, the suspension was subjected to ultrasonication for 30 minutes, transferred to a magnetically stirred hydrothermal kettle, and an inert gas (nitrogen or argon) was introduced into the reactor, the hydrothermal kettle was sealed, and hydrothermal reaction was carried out at 180°C for 6 Hours, after the reaction, naturally cooled to room temperature, the slurry was separated from solid and liquid, washed three times with water and ethanol solution, and dried in a vacuum oven at 100°C for 4 hours to remove free water to obtain carbon-coated lithium iron phosphate Precursor powder material. The carbon-coated lithium iron phosphate precursor powder material is placed in a tube furnace, under the protection of an inert gas...

Embodiment 2

[0052] Prepare lithium hydroxide solution (2mol / L) and ferrous sulfate solution (1mol / L); under stirring conditions, mix lithium hydroxide, ferrous sulfate, and phosphoric acid solution evenly, add 2.5g of glucose, and control the pH of the solution to 6~ 7. Ultrasound the suspension for 30 minutes, transfer it to a magnetically stirred hydrothermal kettle, and pass an inert gas (nitrogen or argon) into the reactor, seal the hydrothermal kettle, and conduct a hydrothermal reaction at 160°C for 10 hours. After the reaction, it was naturally cooled to room temperature, the slurry was separated from solid and liquid, washed three times with water and ethanol solution, and then dried in a vacuum oven at 120°C for 2 hours to remove free water and obtain a carbon-coated lithium iron phosphate precursor powder material. The carbon-coated lithium iron phosphate precursor powder material is placed in a tube furnace, under the protection of an inert gas, heat-treated at a high temperatu...

Embodiment 3

[0055] Prepare lithium hydroxide solution (3mol / L) and ferrous sulfate solution (1mol / L); under stirring conditions, mix lithium hydroxide, ferrous sulfate, and phosphoric acid solution evenly, add 4g of glucose, and control the pH of the solution to 6-7 , the suspension was subjected to ultrasonication for 30 minutes, transferred to a magnetically stirred hydrothermal kettle, and an inert gas (nitrogen or argon) was passed into the reactor, and the hydrothermal kettle was sealed, and hydrothermal reaction was performed at 220 ° C for 3 hours. After the end, cool down to room temperature naturally, separate the slurry from solid and liquid, wash with water and ethanol solution three times, and then dry it in a vacuum oven at 80°C for 6 hours to remove free water and obtain carbon-coated lithium iron phosphate precursor powder Material. The carbon-coated lithium iron phosphate precursor powder material was placed in a tube furnace, and under the protection of an inert gas, it w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com