Agar protococcus biologic fertilizer and preparation method thereof

A technology of bio-fertilizer and agar, applied in fertilization equipment, fertilizer mixture, application, etc., can solve the problems of severe process conditions, single active ingredient of the product, and inability to effectively break algal bodies, so as to achieve simple preparation process and improve stress resistance , The effect of fast absorption and conduction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

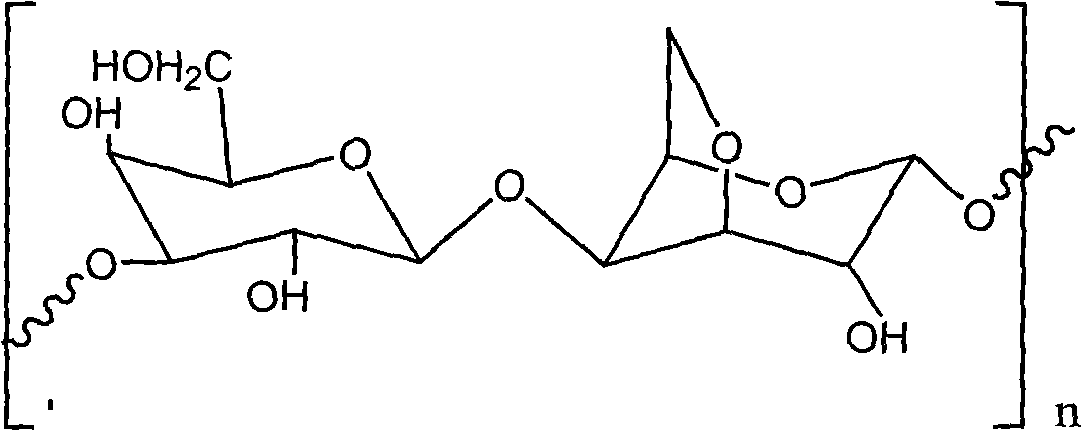

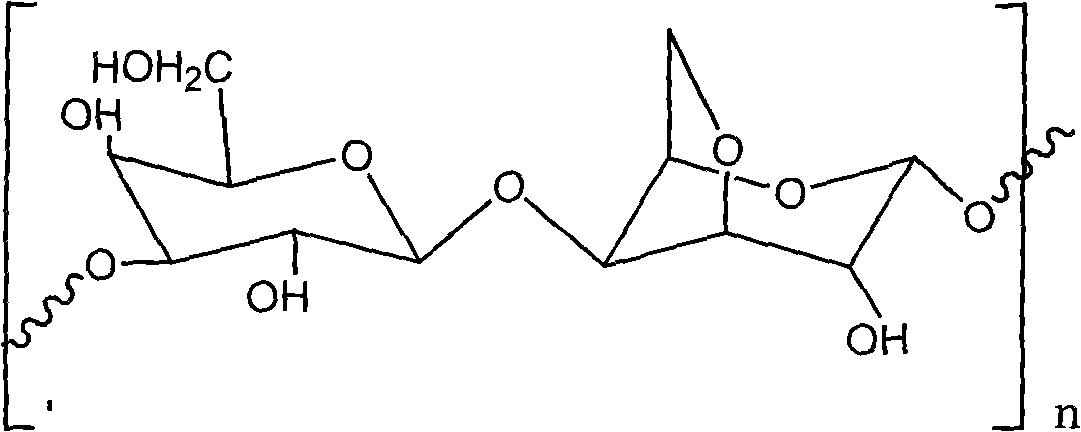

Image

Examples

Embodiment 1

[0024] Take an appropriate amount of finely pulverized laver, add water according to algae:water=1:2 (v / v), stir and extract at 60°C for 12h. The agar-degrading bacteria are activated, expanded to 1 liter of Erlenmeyer flask, shaker culture 24h, the bacterial density in the fermented bacterium liquid that is obtained reaches 20g / L (wet weight), the activity of the agar-degrading enzyme in the fermented bacterium liquid When it reaches 300U / ml, add the laver extract and algae into the fermentation broth at a ratio of 1:10, continue the shaking table reaction for 36 hours, and then remove the residue by suction filtration, and then add the obtained degradation solution at a ratio of 1:1.5 The activated fermentation liquid is subjected to secondary bacterial hydrolysis for 48 hours, and the obtained degradation liquid is the biological fertilizer of the present invention.

Embodiment 2

[0026] Take an appropriate amount of finely crushed agaricus, add water according to algae:water=1:3 (v / v), stir and extract at 55°C for 24h. The agar degrading bacteria is activated, expanded to 3 liters of Erlenmeyer flasks, shaker culture 28h, makes the bacterium density in the fermented bacterium liquid that obtains reach 32g / L (wet weight), the activity of the agar degrading enzyme in the fermented bacterium liquid When it reaches 350U / ml, add the extract of Agaricus japonica along with the algae into the fermentation broth at a ratio of 1:15, continue the reaction in a shaking table for 36 hours, and then remove the slag by suction filtration, and then use the ratio of 1:1.5 to degrade the solution Add the activated fermented bacteria liquid to carry out secondary bacterial decomposition, the time is 36 hours, and the obtained degradation liquid is the biological fertilizer of the present invention.

Embodiment 3

[0028] Take an appropriate amount of finely pulverized Gracilaria, add water according to the ratio of algae: water = 1:3 (v / v), stir and extract in the reactor at 60°C for 24 hours. The agar degrading bacteria are activated, expanded to 100 l fermenters, fermented and cultivated for 36 hours, the bacterial density in the obtained fermented bacterium liquid reaches 18g / L (wet weight), and the activity of the agar degraded enzyme in the fermented bacterium liquid reaches 250U / ml, according to the ratio of 1:10, add the extract of Gracilaria and algae into the fermentation broth, continue to stir and react for 36h, and then remove the slag by suction filtration, and then add the obtained degradation solution into the fermentation broth according to the ratio of 1:1.5 Secondary bacteriolysis is carried out in a new fermenter containing fermentation liquid, and the fermentation time is 48 hours, and the obtained degradation liquid is the biological fertilizer of the present inventi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com