Catalyst for preparing dimethyl ether as well as preparation method and application thereof

A catalyst and dimethyl ether technology, applied in the field of dual-function catalysts, can solve the problems of high reaction temperature, poor catalyst activity and stability, etc., and achieve the effects of uniform physical structure, inhibition of coking, high reactivity and product selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

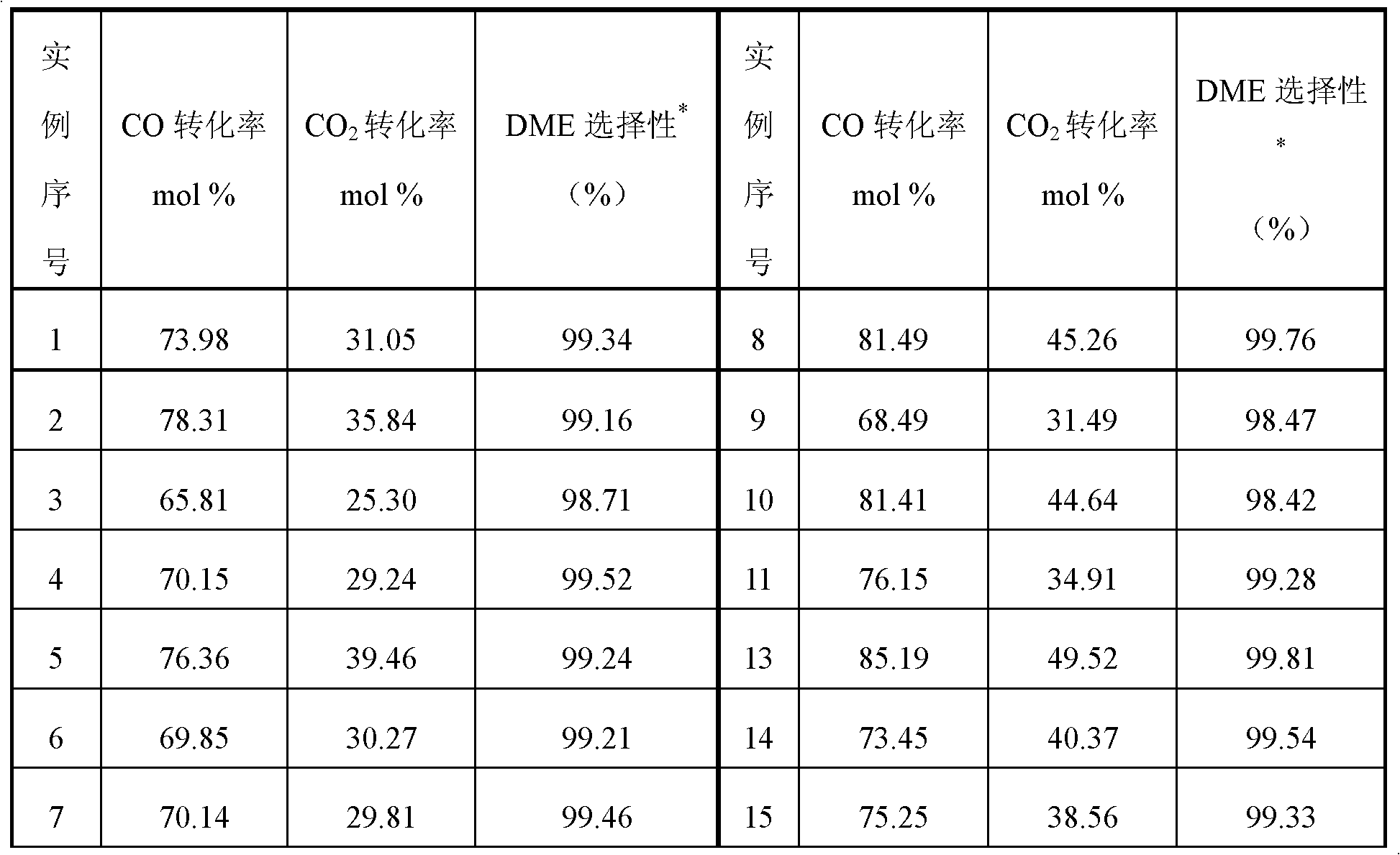

Examples

preparation example Construction

[0033] 1) Preparation of catalyst precursor for methanol synthesis: the nitrate mixed solution of copper, zirconium, third component (one or two substances in lanthanum, manganese, cerium, titanium, iron, chromium, zinc) and sodium carbonate The solution is co-precipitated under the conditions of 40-90°C and pH=7.0-13.0, and the resulting precipitated solution is aged at 40-90°C for 1-6 hours, and the obtained slurry is the catalyst precursor for methanol synthesis; the nitrate is mixed with The mass ratio of copper, zirconium and the third component contained in the solution is 15-65:15-65:0.5-10.

[0034] 2) Preparation of zirconia-alumina mixed oxide precursor: Precipitate the salt solution of zirconium and aluminum and lye at 0-30°C and pH=7.0-13.0 in parallel flow, and add the obtained precipitation solution to the other collective The 5%-50% isopropanol solution is aged at 0-30°C for 4-24 hours, and the obtained slurry is the precursor of zirconia-alumina mixed oxide.

...

Embodiment 1

[0056] 48.4g Cu(NO 3 ) 2 ·3H 2 O, 53.4g ZrO(NO 3 ) 2 2H 2 O and 5.2g La(NO 3 ) 3 ·nH 2 O was dissolved in 600ml of distilled water to make a uniform and stable mixed solution, and mixed with sodium carbonate solution (weighing 50g of anhydrous Na 2 CO 3 Dissolved in 800mL deionized water) and co-precipitated by co-flow, so that the precipitates were evenly mixed. After the precipitation was complete, the precipitation solution was continued to age at 70°C for 2h, and the obtained slurry was the precursor of the methanol synthesis catalyst.

[0057] 13.9g ZrO(NO 3 ) 2 and 68.4g Al 2 (SO 4 ) 3 Dissolve in 300ml of distilled water, and precipitate with 15wt% sodium carbonate solution co-currently at 5°C and pH=7. After the precipitation is complete, add 100ml of isopropanol, age under in-situ conditions for 12 hours, and then filter to obtain a solid sample. Wash the obtained solid sample and add it to the prepared methanol synthesis catalyst precursor slurry, stir ...

Embodiment 2

[0059] With embodiment 1, just with 48.4g Cu (NO 3 ) 2 ·3H 2 O was replaced by 96.8gCu(NO 3 ) 2 ·3H 2 O, to obtain a dimethyl ether synthesis catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com