Sulfonated cross-linked chitosan resin type solid acid catalyst and preparation method thereof

A technology of sulfonated cross-linked chitosan and solid acid catalyst, which is applied in the direction of physical/chemical process catalysts, carboxylate preparation, chemical instruments and methods, etc. It can solve the problems of poor mechanical properties and molding properties, and separation of catalysts and reaction liquids Difficulty, limited application range and other problems, to achieve good mechanical properties and thermal stability, effective catalytic active centers, and excellent physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

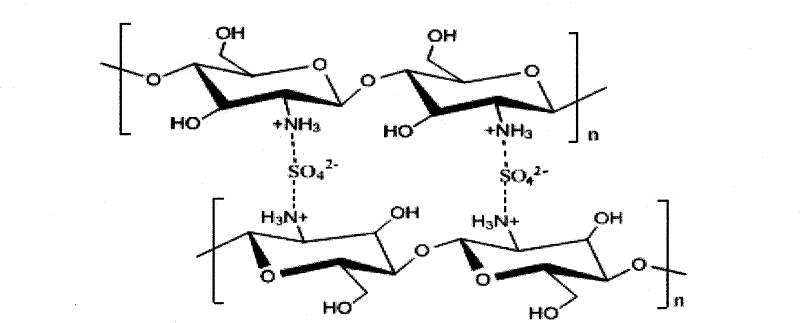

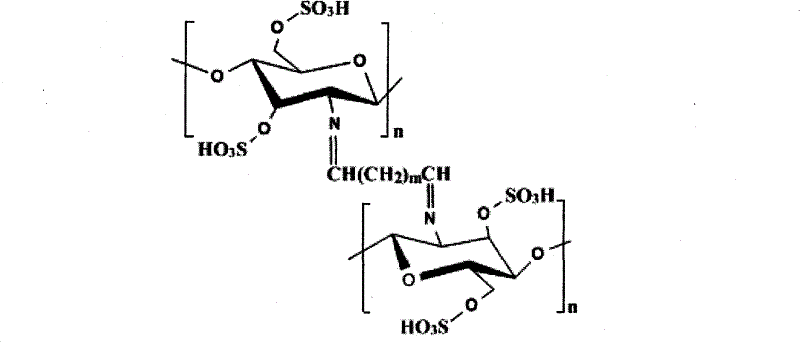

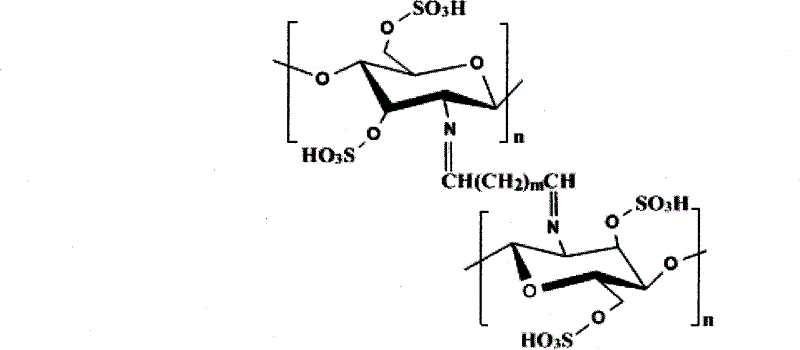

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A kind of preparation method of sulfonated cross-linked chitosan resin type solid acid catalyst, the concrete steps of described method are as follows:

[0028] (1) Preparation of cross-linked chitosan

[0029]With commercially available (deacetylation degree ≥ 95%) chitosan as raw material, by the quality (g) of chitosan: the volume (ml) of cross-linking agent (concentration is 100% glutaraldehyde): mass concentration 2% The volume (ml) of dilute hydrochloric acid solution: the ratio of the mass (g) of the calcium carbonate powder of purity 99.0% is the ratio of 1: 0.5: 50: 0.5, chitosan is joined in described dilute hydrochloric acid solution earlier, stir Chitosan dilute hydrochloric acid solution is prepared until chitosan dissolves. Finally, according to the ratio of Tween-80: dilute chitosan hydrochloric acid solution: the volume ratio of liquid paraffin is 1: 400: 400, first add Tween-80 to the paraffin, stir for 7 minutes and then add dilute chitosan under stir...

Embodiment 2

[0033] A kind of preparation method of sulfonated cross-linked chitosan resin type solid acid catalyst, with embodiment 1, wherein:

[0034] In the (1) step, the quality (g) of described chitosan: the volume (ml) of cross-linking agent (concentration is 100% glyoxal): the volume (ml) of the dilute hydrochloric acid solution of mass concentration 2%: The ratio of the calcium carbonate powder mass (g) of purity 99.0% is 1: 0.1: 70: 0.6, according to Tween-80: chitosan dilute hydrochloric acid solution: the volume ratio of liquid paraffin is 1: 500: 480, the Tween The stirring time for adding -80 to paraffin is 5 minutes, and the stirring time for adding chitosan dilute hydrochloric acid solution is 10 minutes. Add the cross-linking agent and the calcium carbonate powder to the dispersion, and continue stirring for 35 minutes. , heating the reaction solution to 65°C, adjusting the pH value of the system to 9, continuing to stir at a constant temperature of 65°C for 2.3h, and lett...

Embodiment 3

[0037] A kind of preparation method of sulfonated cross-linked chitosan resin type solid acid catalyst, with embodiment 1, wherein:

[0038] In the (1) step, the quality (g) of described chitosan: the volume (ml) of linking agent: the volume (ml) of the dilute hydrochloric acid solution of mass concentration 2%: the calcium carbonate powder quality of purity 99.0% ( g) the ratio is the ratio of 1: 0.4: 60: 0.8, according to the ratio of Tween-80: chitosan dilute hydrochloric acid solution: the volume of liquid paraffin is the ratio of 1: 470: 500, Tween-80 is added to the stirring in the paraffin The time is 10min, the stirring time of adding dilute chitosan hydrochloric acid solution is 5min, the reaction solution is heated up to 70°C, and continues to stir for 2h at a constant temperature at 70°C, according to the quality (g) of the filter cake: the mass concentration is The ratio of the volume (ml) of 2% hydrochloric acid solution is 1: 1.5, and the stirring reaction time t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com