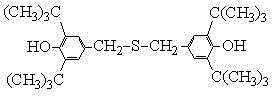

Method for preparing sulfur-containing bisphenol compound antioxidant by means of recycling mother liquor

A kind of technology of sulfur-containing bisphenol, cyclic preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

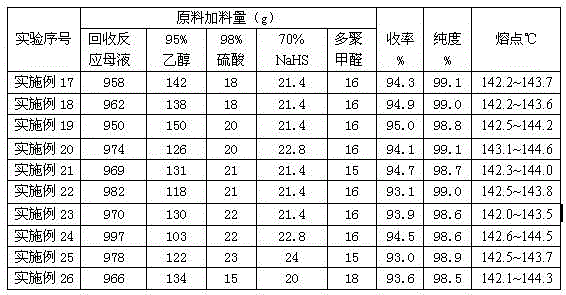

Examples

Embodiment 1

[0050] In the GST-2 type stainless steel autoclave with magnetic stirring, 103g (0.5mol) of raw materials 2,6-di-tert-butylphenol, 28.0g of paraformaldehyde, 1236g of 80% ethanol aqueous solution, 20g of sodium hydroxide, After nitrogen replacement, 25 g of hydrogen sulfide was added. Start stirring and heating, and fully mix the reaction raw materials in the kettle. When the temperature rises to 50~53°C, stop heating, keep the temperature for 70 minutes, and the reaction ends. Cool down to 3~6°C, filter, separate the reaction mother liquor, and collect; the separated methylene-4426-S solid product is washed with 70~80% ethanol aqueous solution to obtain methylene-4426-S with granular pure white crystals Antioxidant product, HPLC purity: 98.7%, melting point: 142.1~143.6℃, yield 94.5%

Embodiment 2

[0052] In the GST-2 type stainless steel autoclave with magnetic stirring, 103g (0.5mol) of raw materials 2,6-di-tert-butylphenol, 32.0g of paraformaldehyde, 1030g of 83% ethanol aqueous solution, 20g of sodium hydroxide, After nitrogen substitution, 18 g of hydrogen sulfide was added. Start stirring and heating, and fully mix the reaction raw materials in the kettle. When the temperature rises to 54~56°C, stop heating, keep warm for 50 minutes, and the reaction ends. Cool down to 3~6°C, filter, separate the reaction mother liquor, and collect; the separated methylene-4426-S solid product is washed with 70~80% ethanol aqueous solution to obtain methylene-4426-S with granular pure white crystals Antioxidant product, HPLC purity: 99.0%, melting point: 142.6~143.5℃, yield 95.2%

Embodiment 3

[0054] In the GST-2 type stainless steel autoclave with magnetic stirring, 103g (0.5mol) of raw materials 2,6-di-tert-butylphenol, 34.0g of paraformaldehyde, 825g of 85% ethanol aqueous solution, 16g of sodium hydroxide, After nitrogen substitution, 15 g of hydrogen sulfide was added. Start stirring and heating, and fully mix the reaction raw materials in the kettle. When the temperature rises to 58~60°C, stop heating, keep warm for 40 minutes, and the reaction ends. Cool down to 3~6°C, filter, separate the reaction mother liquor, and collect; the separated methylene-4426-S solid product is washed with 70~80% ethanol aqueous solution to obtain methylene-4426-S with granular pure white crystals Antioxidant product, HPLC purity: 98.5%, melting point: 142.3~143.8℃, yield 92.8%

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com