Natural nutritional high-water-absorptivity resin and preparation method thereof

A superabsorbent resin and nutrient-based technology, applied in chemical instruments and methods, other chemical processes, applications, etc., can solve problems that have not been reported in superabsorbent composite materials, and achieve improved stress resistance, fast water absorption, and fertile soil Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] (1) Preparation of nutritional superabsorbent resin: Accurately weigh 3g of unnatural sheep manure powder, add it to a four-necked flask filled with 30ml of distilled water, install a stirring device, a condensation device, and a nitrogen protection device. Under reduced pressure conditions (specific pressure 0.01Mpa), heat to 50°C for gelatinization for 25 minutes, cool down to 55°C, add 12 g of acrylic acid, 1.5 g of palygorskite raw ore and 0.0165 g of crosslinking agent and stir at high speed for 5 minutes, then add 0.066 g initiator potassium persulfate, stirred at 65°C for 20 minutes to obtain a cross-linked polymer product. The cross-linked product was taken out, dehydrated twice with anhydrous methanol, washed with anhydrous ethanol, placed in an oven, dried at 70°C, crushed, and passed through a 20-mesh sieve.

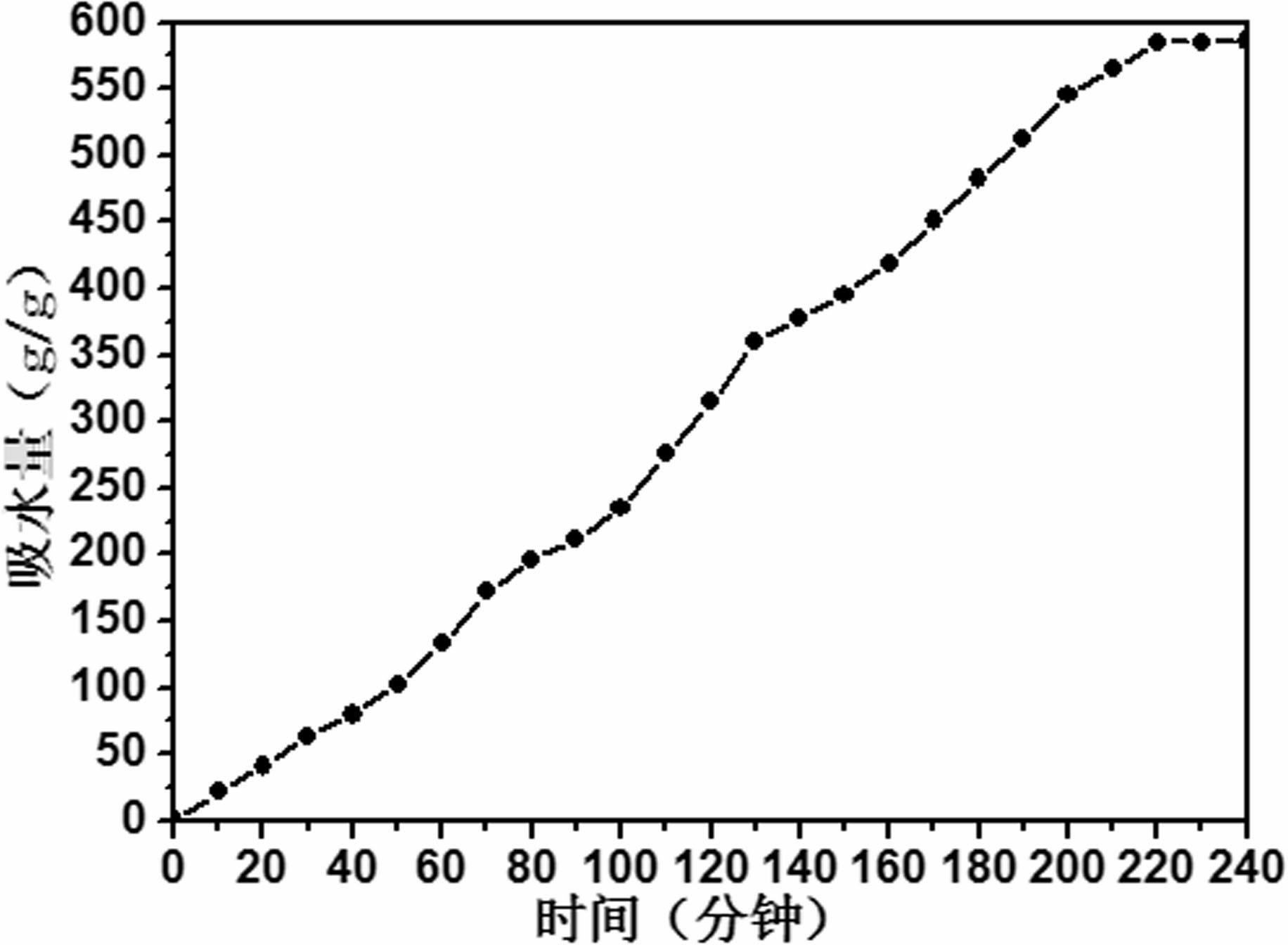

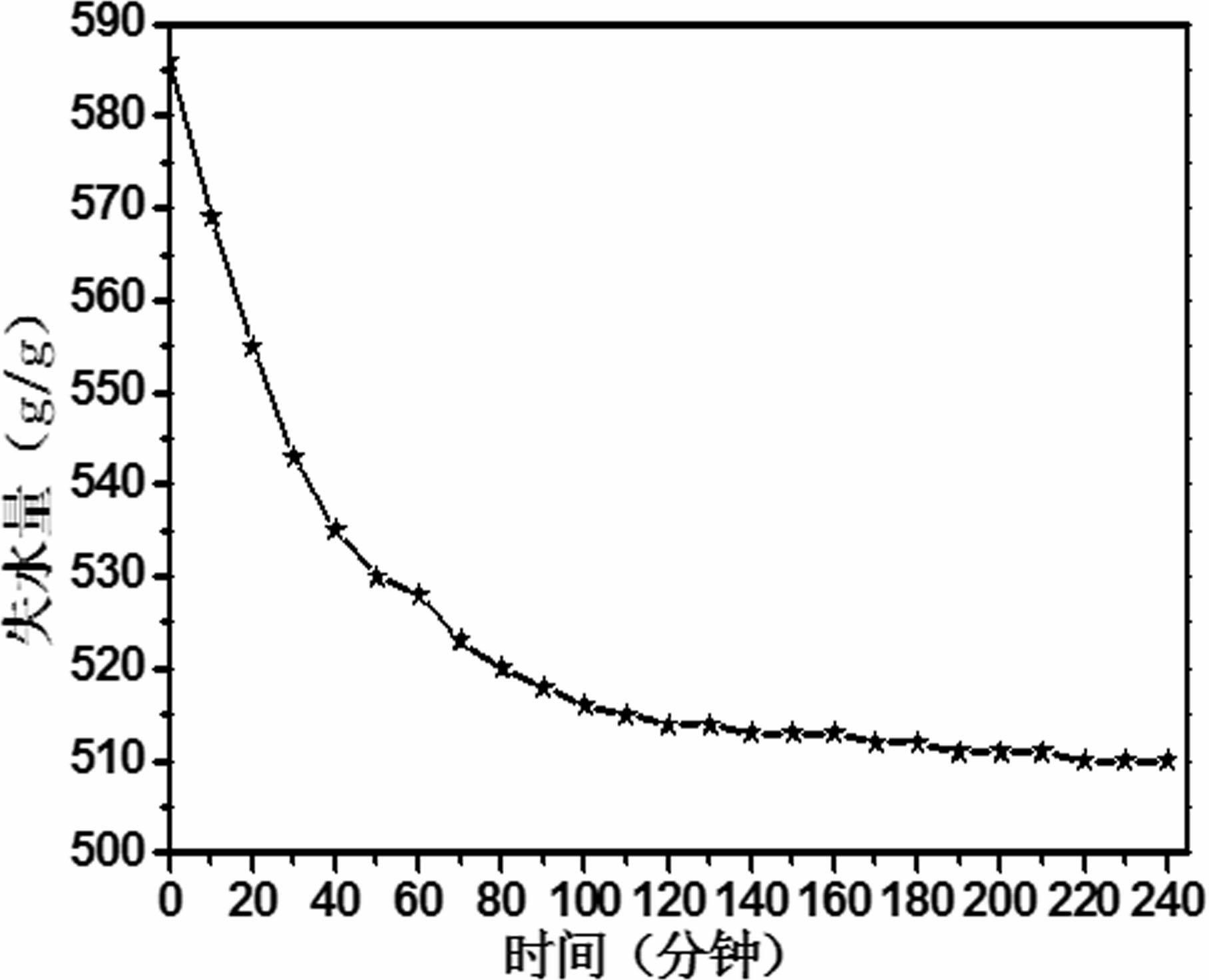

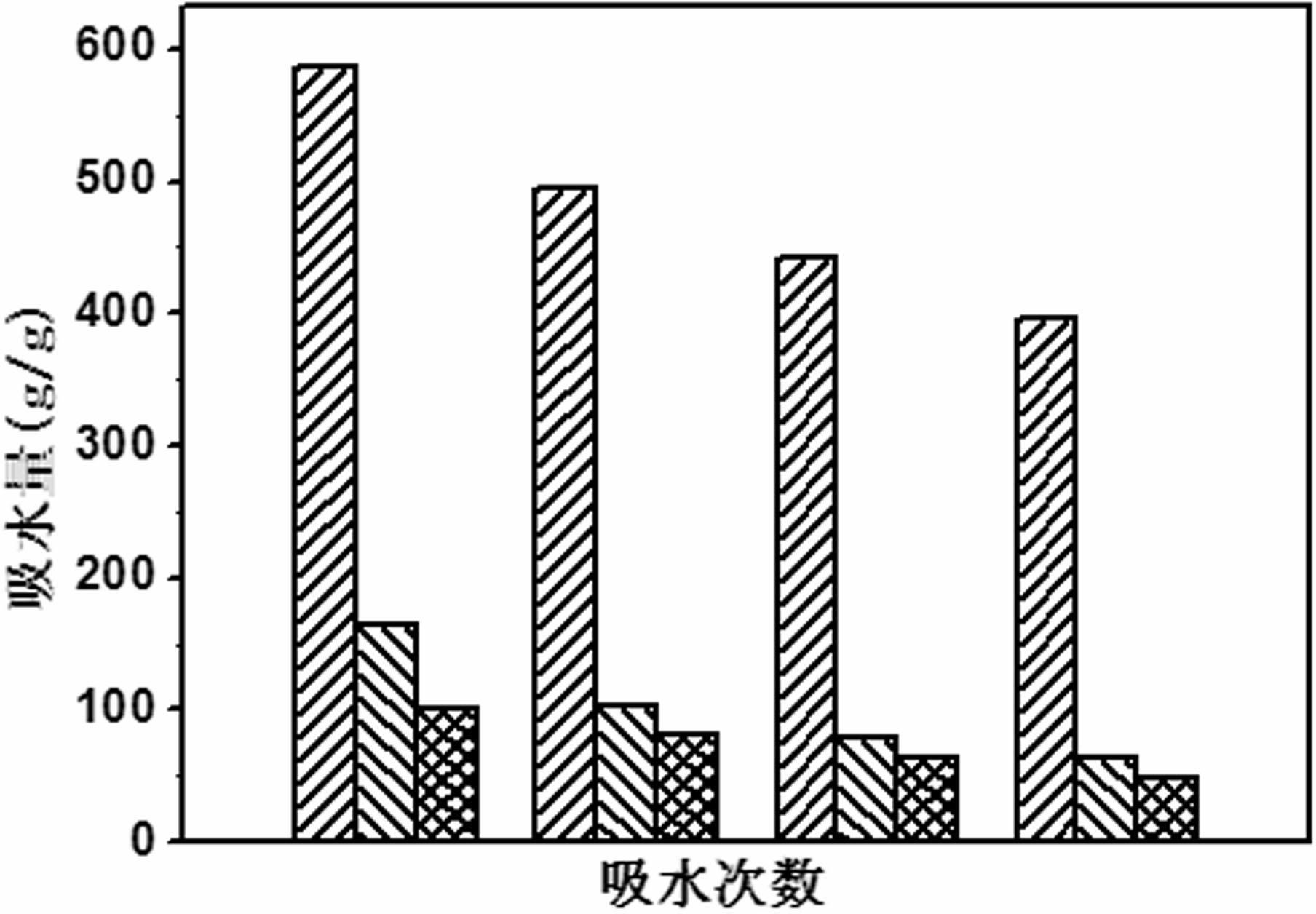

[0054] (2) Performance test

[0055] Water absorption: distilled water 583g / g, sodium chloride solution 146 g / g.

[0056] Gel strength: 182 g / cm 2 ....

Embodiment 2

[0058] (1) Preparation of nutritional superabsorbent resin: Accurately weigh 3g of unnatural sheep manure powder, add it to a four-necked flask filled with 30ml of distilled water, install a stirring device, a condensation device, and a nitrogen protection device. Under reduced pressure conditions (specific pressure 0.02Mpa), heat to 50°C for gelatinization for 25 minutes, cool down to 55°C, add 15 g of acrylic acid, 2.5 g of palygorskite raw ore and 0.041 g of crosslinking agent and stir at high speed for 10 minutes, then add 0.103 g of initiator potassium persulfate was stirred at 70°C for 30 minutes to obtain a cross-linked polymer product. The cross-linked product was taken out, dehydrated twice with anhydrous methanol, washed with anhydrous ethanol, placed in an oven, dried at 70°C, crushed, and passed through a 20-mesh sieve.

[0059] (2) Performance test

[0060] Water absorption: distilled water 547 g / g, sodium chloride solution 110 g / g.

[0061] Gel strength: 190 g / ...

Embodiment 3

[0063] (1) Preparation of nutritional superabsorbent resin: Accurately weigh 3g of unnatural sheep manure powder, add it to a four-necked flask filled with 30ml of distilled water, install a stirring device, a condensation device, and a nitrogen protection device. Under reduced pressure conditions (specific pressure 0.03Mpa), heat to 60 ℃ for gelatinization for 30 minutes, cool down to 60 ℃, add 18 g of acrylic acid, 3.5 g of palygorskite raw ore and 0.049 g of crosslinking agent and stir at high speed for 15 minutes, then add 0.098 g initiator potassium persulfate, stirred at 75°C for 40 min to obtain a cross-linked polymer product. The cross-linked product was taken out, dehydrated twice with anhydrous methanol, washed with anhydrous ethanol, placed in an oven, dried at 70°C, crushed, and passed through a 20-mesh sieve.

[0064] (2) Performance test

[0065] Water absorption: distilled water 580 g / g, sodium chloride solution 137 g / g.

[0066] Gel strength: 179 g / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gel strength | aaaaa | aaaaa |

| Gel strength | aaaaa | aaaaa |

| Gel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com