Degradable thermoplastic rubber membrane using agricultural plant resources as main material and preparation method of degradable thermoplastic rubber membrane

A thermoplastic rubber and plant technology, applied in flat products, other household utensils, applications, etc., can solve the problems of direct processing of materials, complicated preparation process, and expensive materials, etc., and achieves easy industrialization and application, rich raw material resources, The effect of improving the soil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

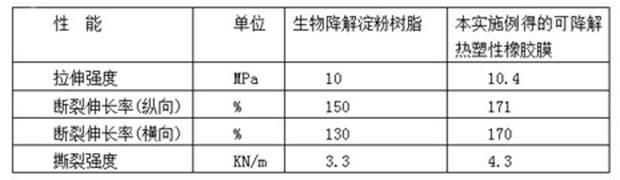

Examples

Embodiment 1

[0035] A method for preparing a degradable thermoplastic rubber film using agricultural plant resources as a raw material, comprising the steps of:

[0036] 1) Raw material selection: according to the weight of each raw material: 80 parts of cotton seed hulls, 80 parts of sisal hemp, 550 parts of potato flour, 50 parts of polyvinyl alcohol, 220 parts of compatibilizing plasticizer (100 parts of glycerin, Malay 20 parts of acid anhydride, 100 parts of polyethylene glycol (PEG-400), 20 parts of functional additives (3 parts of simethicone, 1 part of linoleum oil, 1 part of charantin, 15 parts of β-cyclodextrin), Select raw materials and reserve;

[0037] 2) Raw material pretreatment: put the cottonseed hulls in an ultrafine pulverizer, grind them to 300 mesh and sieve them for later use; put sisal in a fiber grinder, grind them to a particle size of 200 mesh and sieve them for later use; put the dried potato pieces in In an ultrafine pulverizer, grind to 500 mesh and sieve for ...

Embodiment 2

[0070] A method for preparing a degradable thermoplastic rubber film using agricultural plant resources as a raw material, comprising the steps of:

[0071] 1) Selection of raw materials: according to the weight of each raw material: 50 parts of peanut shells, 50 parts of bran shells, 100 parts of straw, 500 parts of konjac flour, 40 parts of high molecular polymers (30 parts of guar gum, polylactic acid 10 parts), 250 parts of compatibilizing plasticizer (30 parts of citric acid ester, 20 parts of polypropylene glycol (600), 200 parts of ethylene glycol), 10 parts of functional additives (4 parts of polyethylene glycol ether (nonyl Phenol polyoxyethylene ether TX-4), 1 part of pectin, 2 parts of L-ascorbic acid, 3 parts of pyrethrum), select raw materials and set aside;

[0072] 2) Raw material pretreatment: put peanut shells and bran shells in an ultrafine pulverizer, grind them to 300 mesh and sieve them for later use; put the straw in a fiber grinder, grind them to a parti...

Embodiment 3

[0085] A method for preparing a degradable thermoplastic rubber film using agricultural plant resources as a raw material, comprising the steps of:

[0086] 1) Raw material selection: according to the weight of each raw material: 100 parts of edamame carob skin, 100 parts of rice straw, 500 parts of konjac flour, 40 parts of high molecular polymer (30 parts of guar gum, 10 parts of polylactic acid), 250 parts of compatibilizing plasticizer (30 parts of citric acid ester, 20 parts of polypropylene glycol (600), 200 parts of ethylene glycol), 10 parts of functional additives (4 parts of polyethylene glycol ether (nonylphenol polyoxyethylene Ether TX-4), 1 part of pectin, 2 parts of L-ascorbic acid, 3 parts of pyrethrum), select plant hulls, plant fibers, plant powders, high molecular polymers, compatibilizers, plasticizers and functional additives raw material, spare;

[0087] 2) Raw material pretreatment: Put the edamame carob skin in an ultrafine pulverizer, grind it to 300 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com