Method for preparing superconductive nanometer device by negative electron beam resist exposure process

A technology of electron beam resist and nano-devices, which is applied in metal material coating technology, technology for producing decorative surface effects, decorative art, etc., can solve the difficulties of making fine lines and dense graphics, electrodes and device ohms Poor contact performance, difficulty in obtaining high-quality samples, etc., to achieve the effect of facilitating electrical measurement, improving efficiency and material utilization, and increasing selection ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

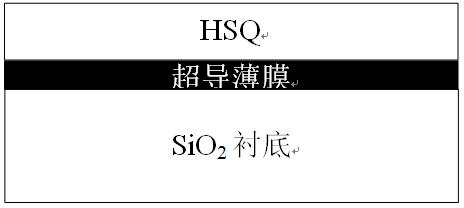

[0060] with SiO 2 Superconducting Nb (niobium) thin films deposited on substrates, electron beam resist HSQ exposure process

[0061] 1. In insulating SiO 2 On the substrate, a superconducting Nb thin film was deposited by magnetron sputtering with a thickness of about 50 nm;

[0062] 2. Use a diamond knife or a wire cutting machine to divide the film into 10mm × 10mm size films;

[0063] 3. Remove debris and other contaminants on the surface of the film by ultrasonic cleaning. After cleaning, use N 2 air dry

[0064] 4. Spin-coat HSQ resist on the surface of the film without pre-spraying, directly accelerate to 4000rpm, rotate for one minute, and the thickness of the glue is about 120nm;

[0065] 5. After the spin coating is completed, place it on a hot plate with a temperature of 170°C and bake for 3 minutes;

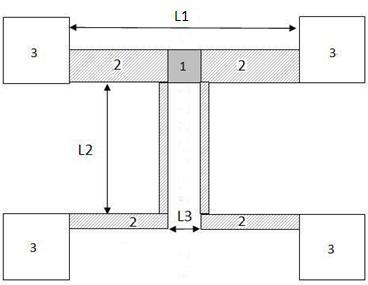

[0066] 6. As image 3 As shown, the fine structure area and the bridge area belong to different layers (I, II), and doses are set for different areas of the exp...

Embodiment 2

[0080] Fabrication of nanoscale superconducting devices—superconducting nano-SQUIDs.

[0081] with SiO 2 Superconducting Nb (niobium) thin films deposited on substrates, electron beam resist HSQ exposure process

[0082] 1. In insulating SiO 2 On the substrate, a superconducting Nb thin film was deposited by magnetron sputtering with a thickness of about 50 nm;

[0083] 2. Use a diamond knife or a wire cutting machine to divide the film into 10mm × 10mm size films;

[0084] 3. Remove debris and other contaminants on the surface of the film by ultrasonic cleaning. After cleaning, use N 2 air dry

[0085]4. Spin-coat HSQ resist on the surface of the film without pre-spraying, directly accelerate to 4000rpm, rotate for one minute, and the thickness of the glue is about 120nm;

[0086] 5. After the spin coating is completed, place it on a hot plate with a temperature of 170°C and bake for 3 minutes;

[0087] 6. Design the exposure pattern of the fine structure region as Fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Line width | aaaaa | aaaaa |

| Lattice constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com