Method for preparing double hydrophilic thermo-sensitive polymer nano micelles

A nano-micelle and polymer technology, applied in the field of nano-micelle preparation, can solve problems such as high experimental conditions, difficult industrialization, and complex preparation process of stimuli-responsive polymers, and achieve simple operation, less time-consuming, and large-scale The effect of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) Synthesis of divinyl adipate:

[0037] Mix 14g of adipic acid with 80mL of vinyl acetate, add 0.2g of copper sulfate catalyst, and react at 70°C to obtain 16g of divinyl adipate, with a yield of 81%;

[0038] (2) Enzymatic synthesis of polymerizable glucose divinyl adipate:

[0039] Add 13.14g of divinyl adipate (0.066mol), 3.96g of glucose, 1.0g of subtilisin and 100mL of anhydrous pyridine into a 250mL Erlenmeyer flask, and put it in a constant temperature shaking incubator at 50°C for 4 days at a speed of 210rpm . The reaction process was qualitatively monitored by thin-layer chromatography (TLC), and the developing solvent was ethyl acetate / methanol / water (volume ratio 17:3:1), and I 2 color. After the reaction was finished, the subtilisin was removed by filtration and most of the pyridine was removed by distillation under reduced pressure, and the crude product was purified by column chromatography, the eluent was pure ethyl acetate, and the developer was et...

Embodiment 2

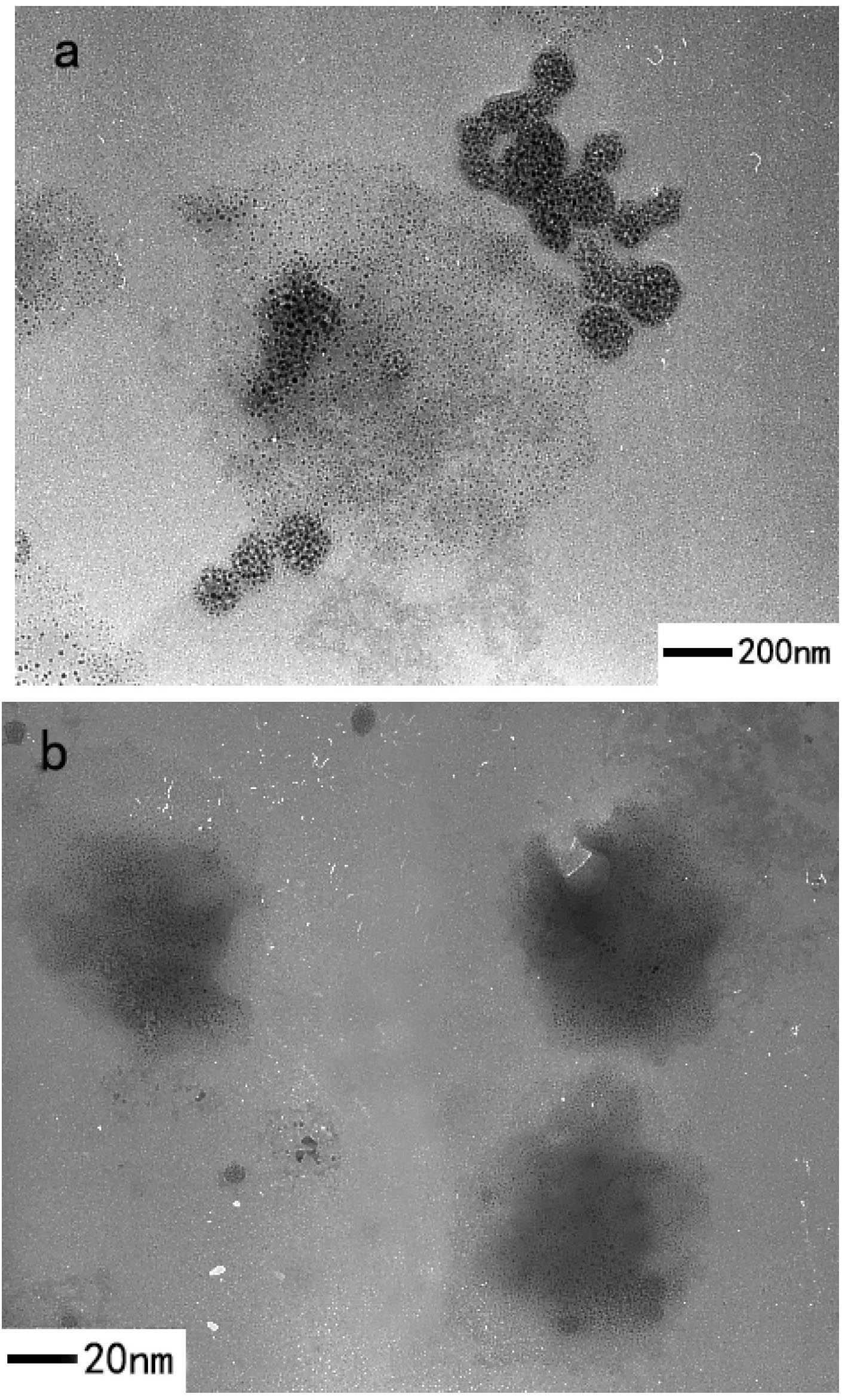

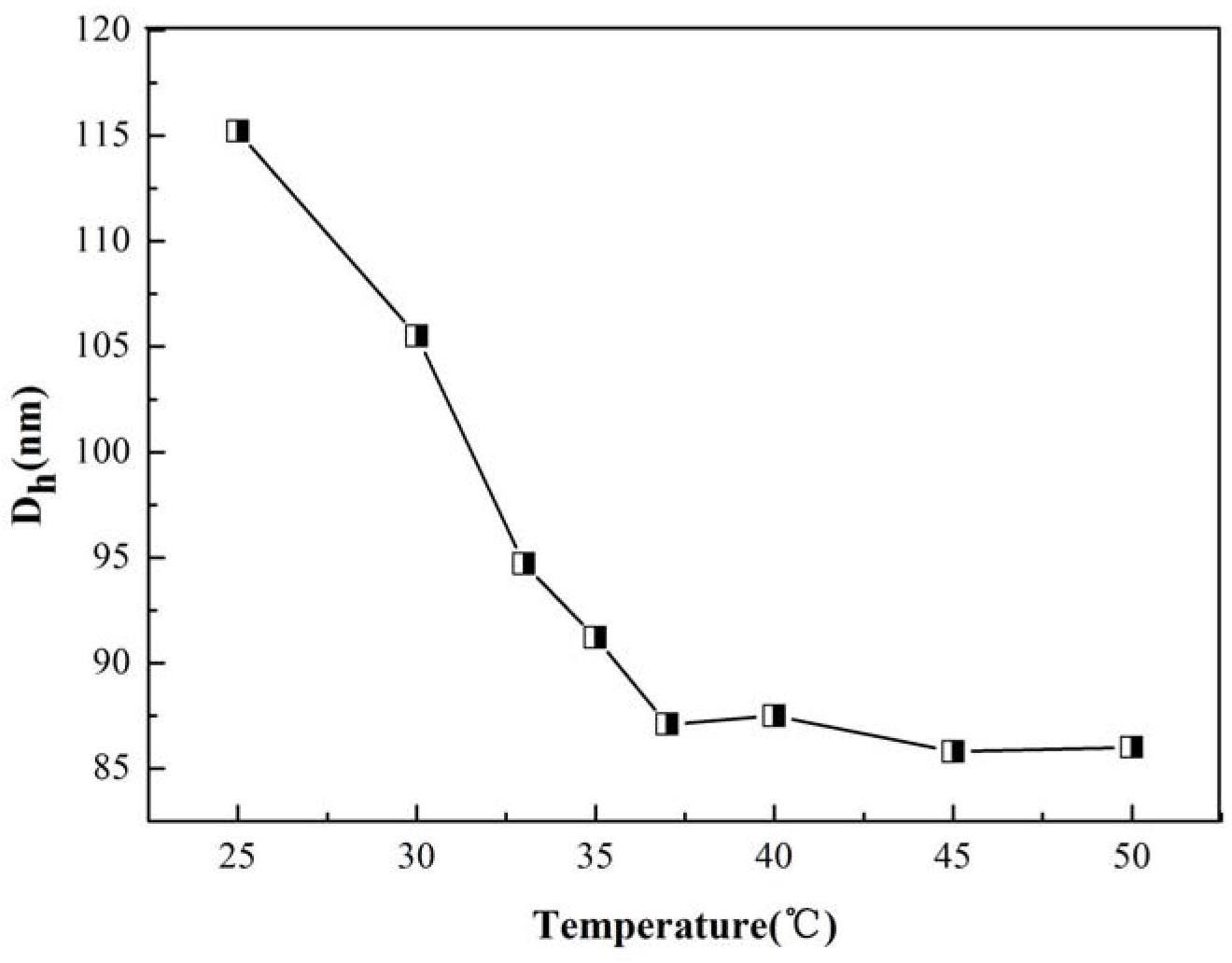

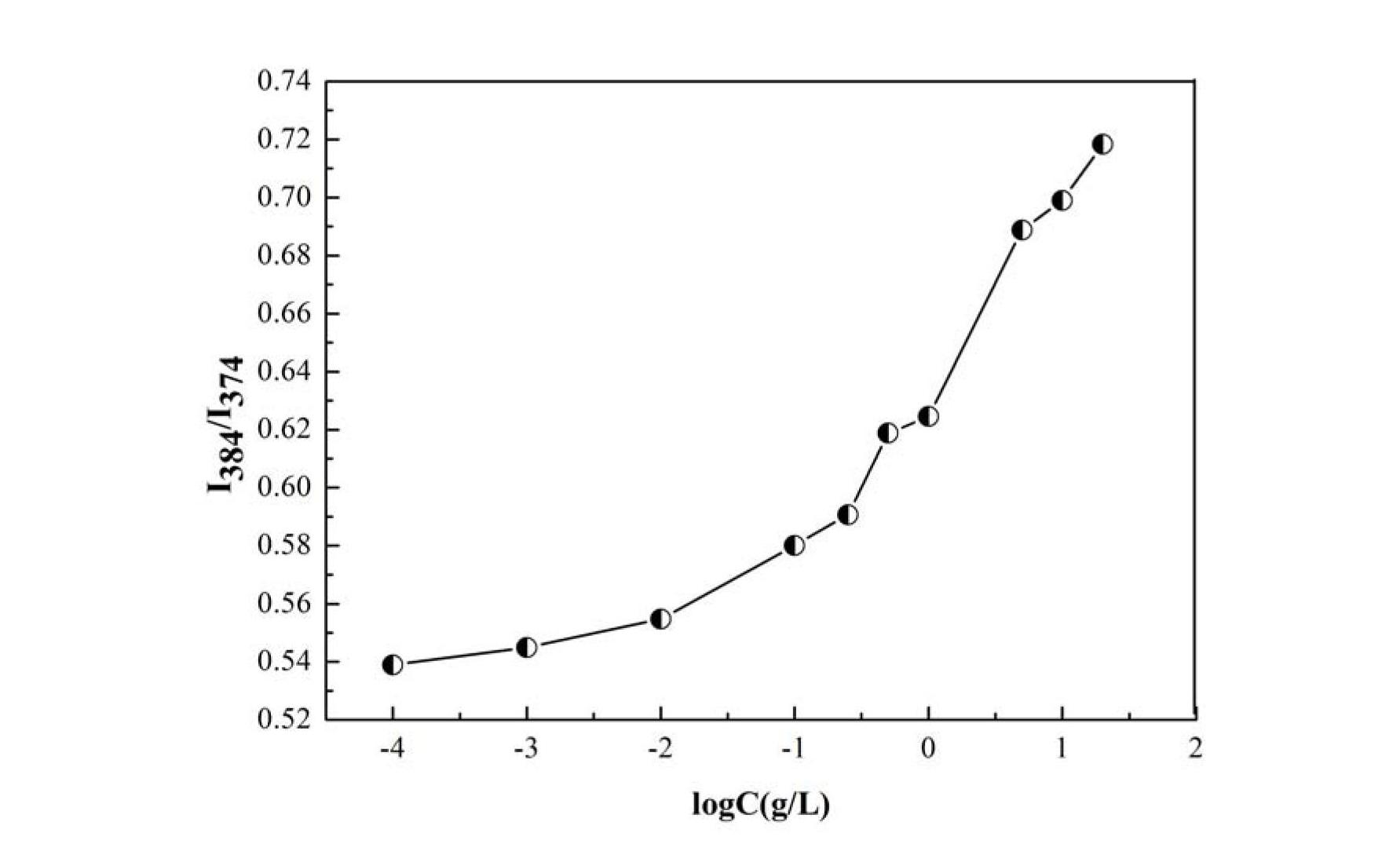

[0041] Add 3.96g of N-isopropylacrylamide, 2.34g of glucose divinyl adipate and 0.126g of AIBN into a flask equipped with a magnetic stirring rotor and an adapter, completely dissolve in 5mL of DMF, seal it, and repeatedly evacuate it. After several times of nitrogen, the reaction system was placed at 60°C under the protection of nitrogen and stirred for 24 hours. After that, the viscous colorless and transparent polymer solution obtained from the reaction was precipitated in a large amount of ether, and the ether was poured out, and the white solid precipitate was again Dissolve in a small amount of ethanol, repeatedly precipitate and dissolve until all unreacted monomers are washed out, and dry in a vacuum oven at 37°C for 24 hours to obtain a white solid powder. 10 g of the obtained polymer powder was weighed and dissolved in 10 mL of double-distilled water, and after complete dissolution, freeze-dried to obtain polymer micelles.

Embodiment 3

[0043]Add 7.92g of N-isopropylacrylamide, 2.34g of glucose divinyl adipate and 0.206g of AIBN into a flask equipped with a magnetic stirring rotor and an adapter, dissolve it completely in 10mL of DMF, seal it, and repeatedly evacuate it. After several times of nitrogen, the reaction system was placed at 60°C under the protection of nitrogen and stirred for 24 hours. After that, the viscous colorless and transparent polymer solution obtained from the reaction was precipitated in a large amount of ether, and the ether was poured out, and the white solid precipitate was again Dissolve in a small amount of ethanol, repeatedly precipitate and dissolve until all unreacted monomers are washed out, and dry in a vacuum oven at 37°C for 24 hours to obtain a white solid powder. 10 g of the obtained polymer powder was weighed and dissolved in 10 mL of double-distilled water, and after complete dissolution, freeze-dried to obtain polymer micelles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com