Preparation method of triethyl phosphate

A technology of triethyl phosphate and absolute ethanol, which is applied in the chemical industry, can solve problems such as high production cost, high equipment requirements, and product damage, and achieve the effects of low production cost, reduced side reactions, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

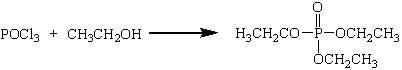

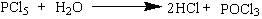

Method used

Image

Examples

Embodiment 1

[0018] Embodiment 1: 276g dehydrated alcohol, 4.2g anhydrous CuCl Join in the reactor that thermometer, constant pressure dropping funnel, mechanical stirring and decompression system are housed, start stirring and decompression device, make under ice bath condition When the temperature in the bottle drops below 5°C, start to add a mixture of 153g of phosphorus oxychloride and 1.5g of phosphorus pentachloride dropwise for 5 hours; after the addition, the temperature is raised to 30°C and kept for 3 hours. It is 2000Pa; continue to heat up to 70°C, and remove excess ethanol and part of hydrogen chloride at 500 Pa for 1 hour; then cool down to room temperature, normal pressure and under cooling conditions, feed ammonia gas while stirring until the pH value of the system 6-7, press filtration to remove the generated ammonium chloride to obtain crude triethyl phosphate. The crude product was rectified at 100 Pa to obtain triethyl phosphate product, 162 g of the product, with a pur...

Embodiment 2

[0019] Embodiment 2: 230g absolute ethanol, anhydrous MgCl22g are joined in the reaction kettle that thermometer, constant pressure dropping funnel, mechanical stirring and decompression system are housed, start stirring and decompression device, under ice bath condition make in bottle When the temperature drops below 5°C, start to drop a mixture of 153g of phosphorus oxychloride and 0.75g of phosphorus pentachloride for 4 hours; after the dropwise addition, raise the temperature to 25°C and keep it warm for 3 hours, and the system pressure during the whole process is 1000Pa Continue to heat up to 70°C, remove excess ethanol and part of hydrogen chloride at 100 Pa for 1.5 hours; then drop to room temperature, normal pressure and under cooling conditions, feed ammonia gas while stirring until the pH of the system is 6-7, press filter to remove the generated ammonium chloride to obtain crude triethyl phosphate. The crude product was rectified at 50 Pa to obtain triethyl phosphat...

Embodiment 3

[0020] Embodiment 3: 184g dehydrated alcohol, TiCl4 6.7g are joined in the reaction kettle that thermometer, constant pressure dropping funnel, mechanical stirring and decompression system are housed, start stirring and decompression device, under the condition of ice bath, make in the bottle When the temperature drops below 5°C, start to add a mixture of 153g of phosphorus oxychloride and 3g of phosphorus pentachloride dropwise, and the dropwise addition time is 4.5h; after the dropwise addition, the temperature is raised to 35°C and kept for 2h, and the system pressure is 1500Pa during the whole process ; continue to heat up to 70 ° C, remove excess ethanol and part of hydrogen chloride at 800 Pa for 1 h; then lower to room temperature, normal pressure and under cooling conditions, feed ammonia gas while stirring until the pH of the system is 6 -7, remove the generated ammonium chloride by pressure filtration to obtain the crude product of triethyl phosphate. The crude produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com