Bio-macromolecular hydrogel and preparation method thereof

A technology of biological macromolecules and hydrogels, which can be used in inactive components of polymer compounds, medical science, prostheses, etc. It can solve the problems of poor mechanical strength, reduced biocompatibility, cytotoxicity, etc., and achieve good mechanical properties. , The preparation method is simple, and the biocompatibility is good.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of the biomacromolecule hydrogel of the present invention: dissolve the polysaccharide macromolecule in deionized water to obtain a polysaccharide macromolecule aqueous solution, dissolve proteins or polypeptides in the polysaccharide macromolecule aqueous solution, or add additives to obtain a macromolecular mixed solution . Add an enzyme catalyst, mix evenly, and catalyze the cross-linking reaction at 0°C-50°C for 0.5-24 hours to cross-link the protein or polypeptide to obtain a semi-interpenetrating network hydrogel. The semi-interpenetrating network hydrogel is further cross-linked by divalent ions to obtain a high-strength biomacromolecular hydrogel with an interpenetrating network structure. The protein is one or more of collagen, gelatin, silk fibroin, zein, elastin, and fibronectin; the polypeptide or molecule containing amino acid residues is a small molecule peptide containing lysine and glutamine or One or more of oligomers; polysaccha...

Embodiment 1

[0034] Weigh 0.6g of sodium alginate and dissolve it in 20ml of deionized water to obtain a sodium alginate aqueous solution with a mass concentration of 3%. Weigh 3g of gelatin and add it to the above sodium alginate aqueous solution, heat and dissolve in a water bath at 50°C, and let it stand for defoaming. A homogeneously mixed gelatin and sodium alginate macromolecular aqueous solution is obtained.

[0035] Add 0.5ml of transglutaminase solution with a concentration of 100 U / ml, mix quickly and evenly, place in a flat plate or a columnar mold, and react and crosslink at 40°C for 1 hour to obtain a protein semiinteractive protein crosslinked by gelatin through a peptide bond. Penetrating network hydrogel, which contains alginate macromolecules.

[0036] The obtained semi-IPN hydrogel was taken out from the mold and immersed in a calcium chloride solution with a molar concentration of 5 mol / L for 1 hour to obtain a film-like or block-like interpenetrating network biomacromol...

Embodiment 2

[0039] Weigh 0.1g of guar gum and dissolve it in 10ml of deionized water to obtain an aqueous solution of guar gum with a mass concentration of 1%. Weigh 1g of gelatin and add it to the above aqueous solution of sodium alginate, heat and dissolve in a water bath at 50°C, and let it stand for defoaming. Obtain evenly mixed guar gum and gelatin macromolecular aqueous solution.

[0040] Add 0.5ml of microbial transglutaminase solution with a concentration of 50U / ml, mix quickly and uniformly, place in a tubular or columnar mold, and react and crosslink at 40°C for 1 hour.

[0041] The obtained semi-IPN hydrogel was taken out from the mold, soaked in a CaHPO4 solution with a molar concentration of 10 mol / L for 1 hour, and a tubular or block-shaped interpenetrating network biomacromolecule hydrogel was obtained. The obtained hydrogel is repeatedly washed with water to remove residual calcium ions, and then stored in a deionized aqueous solution. Further freeze-dried at -80°C to ob...

PUM

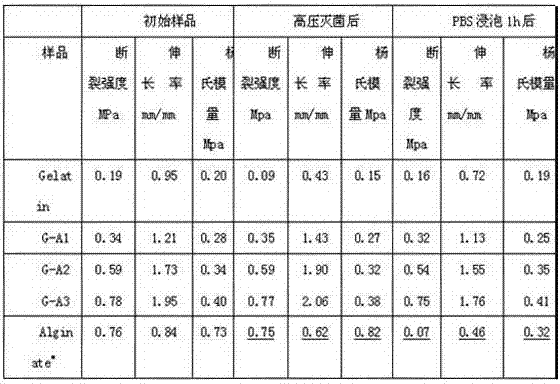

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com