Method for preparing (-) gamma-lactam by catalysis asymmetry of microorganism

A microorganism and lactam technology, applied in the field of bioengineering, can solve the problems of unfavorable industrial production and low substrate concentration, and achieve the effects of high stereoselectivity, high reaction yield and high product concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Example 1: Screening of microbial strains with lactamase activity

[0025] More than 20 soil samples collected near the local chemical factory were diluted with sterile water and left to stand, then the supernatant was inoculated on the enrichment medium, and the enriched cultured bacteria solution was spread on the plate screening medium, at 30°C Cultivate for 2-3 days, pick a single colony, and measure the activity.

[0026]The single colony obtained by screening was inserted into the fermentation medium, and cultured at 30°C and 110 r / min for 48 h. Then the wet cells obtained by centrifugation were suspended in phosphate buffer solution (0.05 mol / L, pH 7.0), the concentration of wet cells was 50 g / L, and the concentration of substrate (±) γ-lactam was 10 g / L. React at 30°C and 180 r / min, take samples within 48 h, remove the bacteria from the transformation solution by centrifugation, extract the supernatant with ethyl acetate, add an appropriate amount of anhydrous ...

Embodiment 2

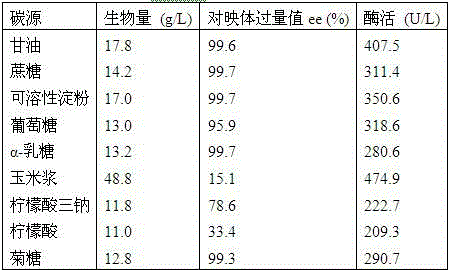

[0029] Embodiment 2: the impact of different carbon sources on fermentation enzyme production

[0030] With peptone (10%) and yeast extract (5%) as nitrogen sources, the following carbon sources were added at a concentration of 3%: glucose, α-lactose, inulin, sucrose, soluble starch, citric acid, trisodium citrate, glycerin , corn steep liquor, as a fermentation medium, and for the hydrolysis of racemic γ-lactam. The transformation solution after the microbial catalytic reaction was centrifuged to separate the bacteria, and the supernatant was extracted with ethyl acetate, dried by adding an appropriate amount of anhydrous magnesium sulfate, and then detected by chiral HPLC. To investigate the effect of different carbon sources on bacterial strains Delftia Sp. CGMCC 5755 Fermentation Enzyme Production and Effect of Product Optical Purity.

[0031] It can be seen from Table 2 that the carbon source has little influence on the biomass of the bacteria, but has a great influen...

Embodiment 3

[0034] Embodiment 3: the impact of different nitrogen sources on fermentation enzyme production

[0035] Add yeast extract, corn steep liquor, beef extract, urea, peptone, ammonium bicarbonate, diammonium hydrogen citrate, and ammonium chloride at a concentration of 30 g / L on the medium with sucrose as the carbon source , ammonium acetate, and diammonium hydrogen phosphate as the nitrogen source of the fermentation medium, for Delftia The biomass and enzyme production of sp. CGMCC 5755 strain were studied. The results are shown in Table 3. Compared with the control (beef extract 3 g / L, peptone 10 g / L) when a single nitrogen source was used, the ee values were lower. Therefore, beef extract and peptone were selected as the compound nitrogen source for bacterial fermentation to produce enzyme.

[0036] Table 3 Effect of nitrogen source on fermentation enzyme production

[0037]

[0038] "-" indicates that the ee value and enzyme activity were not determined because the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical purity | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

| optical purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com