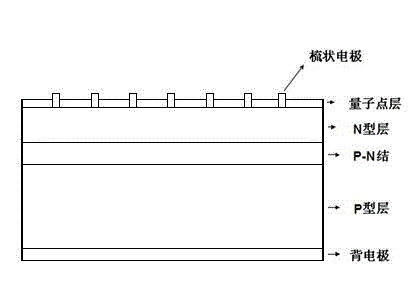

Nanocrystalline/quantum dot sensitive silicon substrate battery piece and preparation method thereof

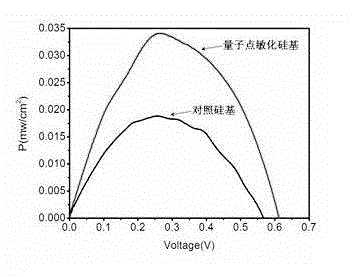

A technology of sensitizing silicon-based and quantum dots, which is applied in the field of photoelectric materials and solar cells, can solve the problems of no obvious improvement in solar light energy absorption and conversion efficiency, increase production costs, and limit device efficiency, etc., and achieve photocurrent density and photoelectricity. Effects of increased conversion efficiency, reduced reflection loss, and improved absorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

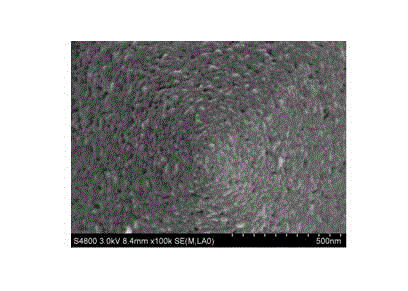

[0027] In this example, the metal source and sulfur source solutions are prepared separately, and after mixing them to make quantum dots, the pretreated silicon-based cells are quickly put into them, and the silicon-based cells are dipped and pulled in a chemical bath The surface of the battery sheet reacts to form firm and dense nanocrystals / quantum dots. The specific steps are as follows:

[0028] a. Preparation of nanocrystals / quantum dots by pre-synthesis

[0029] Prepare copper acetate [(CH3COO)2Cu.H2O] / ethanol solution with a concentration of 0.01-0.5mol / l and 0.15mol / l thioacetamide [CH3CSNH2] / ethanol solution, mix them, and stir evenly. At this time, a small amount of copper sulfide quantum dots will be generated in the solution, and these quantum dots will serve as crystal seeds for the growth of quantum dots on the surface of silicon-based cells.

[0030] b. Pretreatment of silicon-based cells

[0031] Put the silicon-based cells vertically into ethanol for ultraso...

Embodiment 2

[0036] a. Preparation of quantum dots by pre-synthesis method

[0037] Take lead acetate and thioacetamide with a concentration of 0.01-0.5mol / l as the metal source and sulfur source respectively, mix the metal source and the sulfur source into a container, add a surfactant, and stir evenly.

[0038] b. Pretreatment of silicon-based cells

[0039] First place the silicon-based cell vertically in ethanol for 2-10 minutes of ultrasonic cleaning, rinse with water, and rinse at 30-60 O Under C, wash with a mixed solution of distilled water: H2O2: ammonia water = 2:1:1-9:1:1 for 2-10 minutes, and then vertically put it into a hydrofluoric acid solution diluted to 30% with ethanol or pure water for corrosion , ultrasonic 2-10min, after taking out, rinse with ultrapure water.

[0040] c. Deposition and growth of nanocrystals / quantum dots

[0041] Put the treated silicon-based battery sheet vertically into the mixed solution of lead acetate and thioacetamide that has been unifo...

Embodiment 3

[0043] a. Preparation of quantum dots

[0044] Prepare a tin tetrachloride / ethanol solution with a concentration of 0.01-0.5mol / l, and prepare a thioacetamide / ethanol solution with a concentration of 0.01-0.15mol / l at the same time as the metal source and sulfur source respectively, and mix the metal source and sulfur source , stir well.

[0045] b. Pretreatment of silicon-based cells

[0046] Put the silicon-based cell vertically into ethanol for ultrasonic cleaning for 2-10 minutes, rinse with water, O Under C, wash with a mixed solution of distilled water: H2O2: ammonia water = 2:1:1-9:1:1 for 2-10 minutes, and then vertically put it into a hydrofluoric acid solution diluted to 30% with ethanol or pure water for corrosion. Sonicate for 2-10min, take it out, and rinse it with ultrapure water.

[0047] c. Deposition and growth of nanocrystals / quantum dots

[0048] Put the pretreated silicon-based battery sheet vertically into a uniformly mixed solution of tin tetrachlorid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com