Antimicrobial thermal-insulation coating for fabrics and preparation method thereof

A heat-insulating coating and fabric technology, applied in plant fibers, textiles, papermaking, fiber processing, etc., can solve problems such as eye irritation, skin irritation, and upper respiratory tract irritation, and achieve good heat and sun rays. Good stability and practicability, the effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

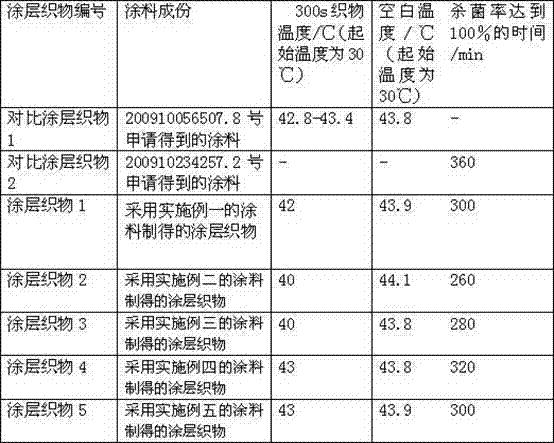

Examples

Embodiment 1

[0031] The preparation process of the antibacterial heat-insulating coating fabric coating of the present invention is as follows:

[0032] 1. Add 0.1mol of Al 2 (SO 4 ) 3 .18H 2 O and water are prepared into 0.2mol / L solution A, and 0.8mol (NH 4 ) 2 CO 3 Prepare 0.8 mol / L solution B with water, add 0.02 mol of MgSO 4 ·7H 2 O and water were prepared into a 0.8 mol / L solution C, and the three solutions A, B, and C were mixed according to the same volume, and the pH was adjusted to 7 with ammonia water, and the system was stirred and matured for 10-20 minutes, and then left for 2 hours. Then wash with deionized water and ethanol for 3-5 times respectively, dry at 130°C for 1 hour, and then burn at 685°C for 1 hour to obtain nano-scale magnesium-containing alumina; the particle size of magnesium-containing alumina is 70-100nm;

[0033] 2. Then add 20 mL of absolute ethanol to 0.015 mol zinc alkyl xanthate to obtain a zinc alkyl xanthate solution with a molar concentration...

Embodiment 2

[0037] The preparation process of the antibacterial heat-insulating coating fabric coating of the present invention is as follows:

[0038] 1. Add Al 2 (SO 4 ) 3 .18H 2 O and water are prepared into 0.2mol / L solution A, and (NH4 ) 2 CO 3 Prepare 0.8 mol / L solution B with water, MgSO 4 ·7H 2 O and water were prepared into a 0.8 mol / L solution C, and the three solutions A, B, and C were mixed according to the same volume, and the pH was adjusted to 7 with ammonia water, and the system was stirred and matured for 10-20 minutes, and then left for 2 hours. Then wash with deionized water and ethanol for 5 times, dry at 130°C for 1 hour, and then burn at 695°C for 1 hour to obtain nano-sized magnesium-containing alumina;

[0039] 2. Then add ethanol to the zinc alkyl xanthate to obtain a zinc alkyl xanthate solution with a molar concentration of 0.75 mol / L, and slowly add 0.05 mol / L Na 2 S solution, titration rate 5mL / min, forming D solution, wherein Na 2 The mol ratio of S...

Embodiment 3

[0043] The preparation process of the antibacterial heat-insulating coating fabric coating of the present invention is as follows:

[0044] Wherein 1-3 steps are as embodiment two.

[0045] 4. The weight percentage of each component in the composite coating layer coating is: 25% ethanol; 7% dioctyl phthalate; 0.8% polyvinyl formal; Ethylene glycol 9%, the rest is polyurethane. The above-mentioned ingredients are mixed and stirred evenly to form the antibacterial and heat-insulating coating fabric coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com