Methane fermenting method

A biogas fermentation and biogas technology, applied in fermentation, waste fuel, biosynthesis, etc., can solve the problems of accumulation, obvious inhibitory factors for a single material, long fermentation time, etc. The effect of decomposition and utilization promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

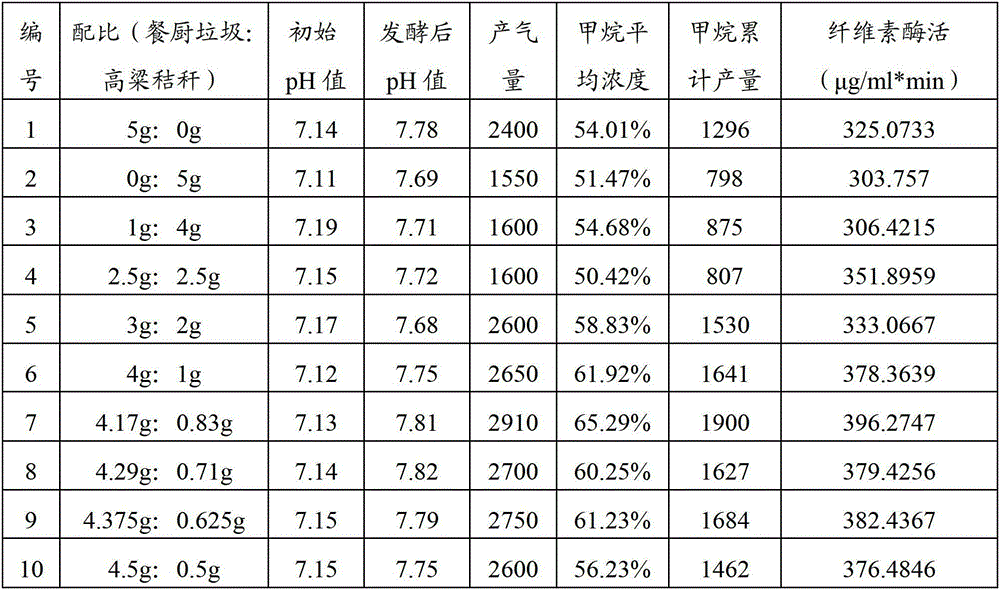

[0022] Example 1: Biogas fermentation test

[0023] 1. Biogas fermentation raw materials

[0024] Biogas inoculum: sludge taken from Beijing sewage treatment plant;

[0025] Food waste: taken from the canteen of Beijing University of Chemical Technology, of which protein 15.14%, soluble sugar 33.38%, crude fat 25.24%, crude fiber 7.58% (mass percentage);

[0026] Sweet sorghum straw: taken from farmland in the suburbs of Beijing;

[0027] 2. Domestication of biogas inoculum

[0028] Initial acclimatization (7 days): Add glucose to the sludge to a concentration of 1g / L, the reactor operation cycle is 24h, the time allocation is 7h aeration, 3h static, and 14h idle. Replace 1 / 3 volume of supernatant with the initial sludge after each idle, and maintain the dissolved oxygen concentration at 2-3mg / L;

[0029] Mid-term domestication (5 days): Add glucose to the initial domesticated sludge to a concentration of 1g / L, and add 10% of the mass of the biogas inoculum after the initial domesticatio...

Embodiment 2

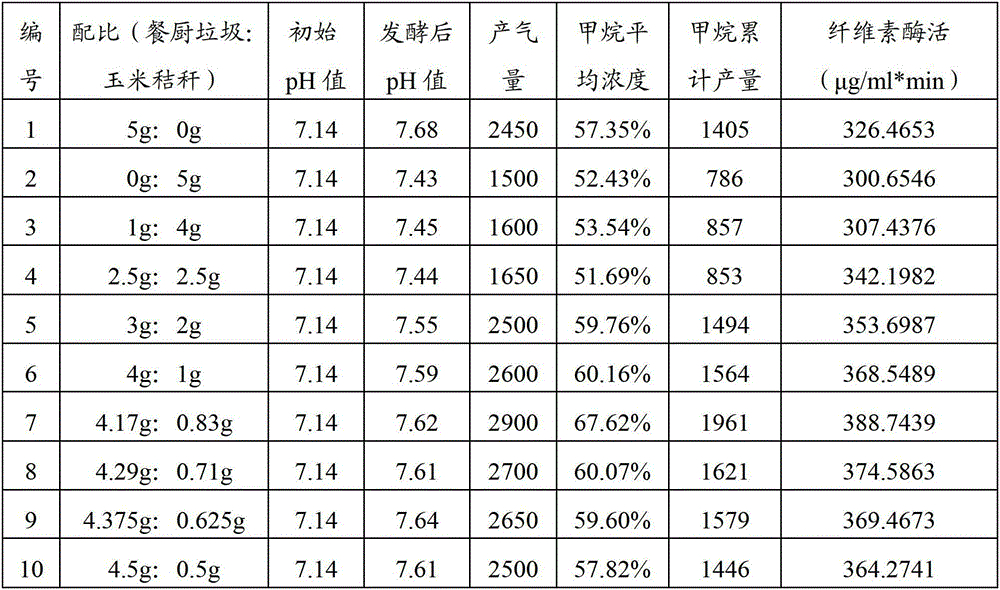

[0039] Example 2: Biogas fermentation test

[0040] 1. Biogas fermentation raw materials

[0041] Biogas inoculum: biogas residue taken from the biogas digester in Donghuashan Village, Shunyi District, Beijing;

[0042] Food waste: taken from the canteen of Beijing University of Chemical Technology, of which protein 15.14%, soluble sugar 33.38%, crude fat 25.24%, crude fiber 7.58% (mass percentage);

[0043] Corn stalks: taken from farmland in the suburbs of Beijing;

[0044] 2. Domestication of biogas inoculum

[0045] Initial acclimatization (7 days): Add glucose to the biogas residue to a concentration of 1g / L, the reactor operation cycle is 24h, and the time allocation is 7h aeration, 3h static, and 14h idle. Replace 1 / 3 volume of supernatant with the initial biogas residue after each idle, and maintain the dissolved oxygen concentration at 2-3mg / L;

[0046] Mid-term domestication (5 days): Add glucose to the biogas residue after the initial domestication to a concentration of 1g / L, ...

Embodiment 3

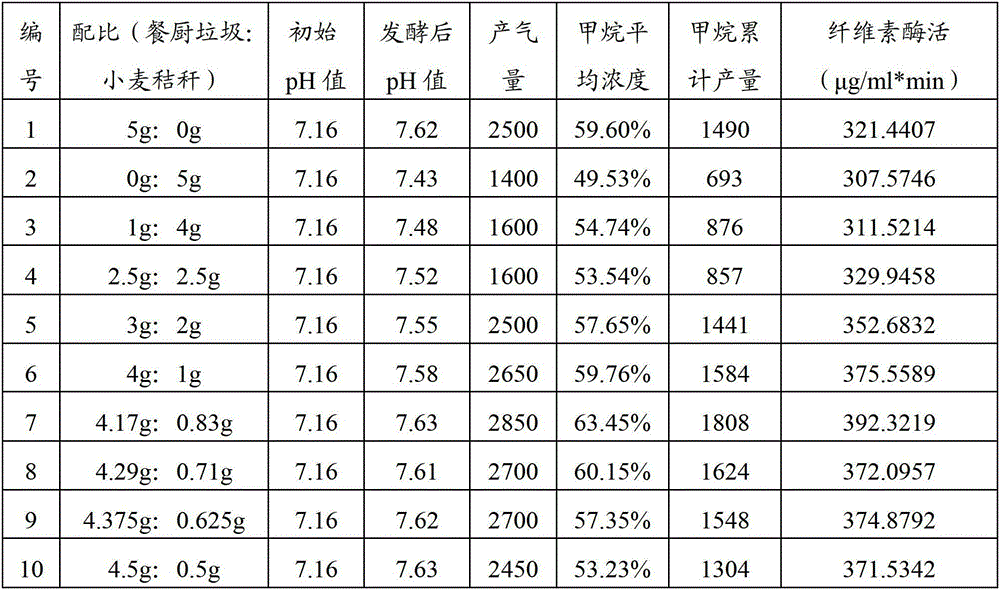

[0056] Example 3: Biogas fermentation test

[0057] 1. Biogas fermentation raw materials

[0058] Biogas inoculum: sewage taken from a food factory in Beijing;

[0059] Food waste: taken from the canteen of Beijing University of Chemical Technology, of which protein 15.14%, soluble sugar 33.38%, crude fat 25.24%, crude fiber 7.58% (mass percentage);

[0060] Wheat straw: taken from farmland in the suburbs of Beijing;

[0061] 2. Domestication of biogas inoculum

[0062] Initial acclimatization (7 days): Add glucose to the sewage to a concentration of 1g / L, the reactor operation cycle is 24h, the time is allocated as aeration for 7h, static sinking for 3h, and idle for 14h. Replace 1 / 3 of the supernatant with the initial sewage after each idle, and maintain the dissolved oxygen concentration at 2-3mg / L;

[0063] Mid-term domestication (5 days): Add glucose to the initial domesticated sewage to a concentration of 1g / L, and add food waste that accounts for 10% of the initial domesticated se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com