Method for preparing natural material inorganic nanoparticle composite nano-fiber through electrostatic spinning

A technology of composite nanofibers and inorganic nanoparticles, which can be used in fiber processing, chemical characteristics of fibers, and medical preparations with inactive ingredients, etc. Low cost, good application prospect, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

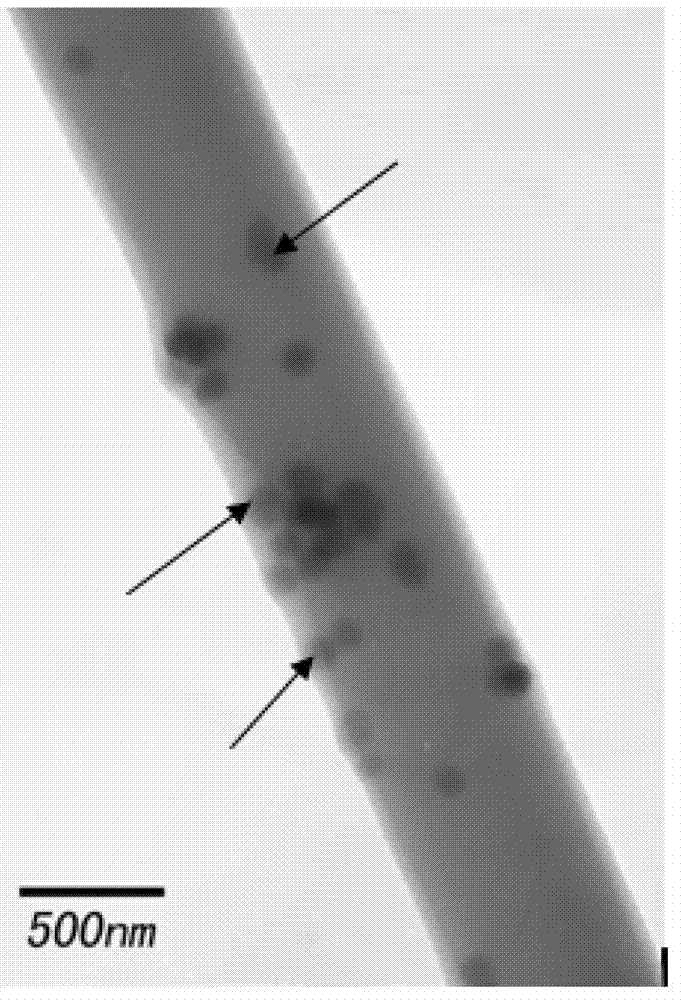

[0030] Gelatin Nanofiber Scaffolds Loaded with Mesoporous Silica

[0031] (1) Preparation of silica nanoparticles by template extraction method: Add 1.0g of template agent (hexadecyltrimethyl) to 500ml of 3% NaOH dilute alkaline aqueous solution, heat the oil bath to 80°C, and stir for 1.5h , add 5 ml of tetraethyl orthosilicate dropwise, wash and centrifuge with deionized water and ethanol, repeat three times and then dry. Reflux in a mixture of 5 ml of 38% HCL and 500 ml of absolute ethanol to remove the template agent to obtain freeze-dried mesoporous silicon;

[0032] (2) Prepare gelatin hexafluoroisopropanol solution with a mass volume ratio of 1:10 (g / ml);

[0033] (3) The amount of mesoporous silicon added is 10% relative to the mass of gelatin, the solution is sucked with a syringe, the voltage is adjusted to 18kV, the advancing speed is 1.0ml / h, the receiving distance is 15cm, the room temperature is 60%, and the humidity is 60%. Gelatin-mesoporous silica composite ...

Embodiment 2

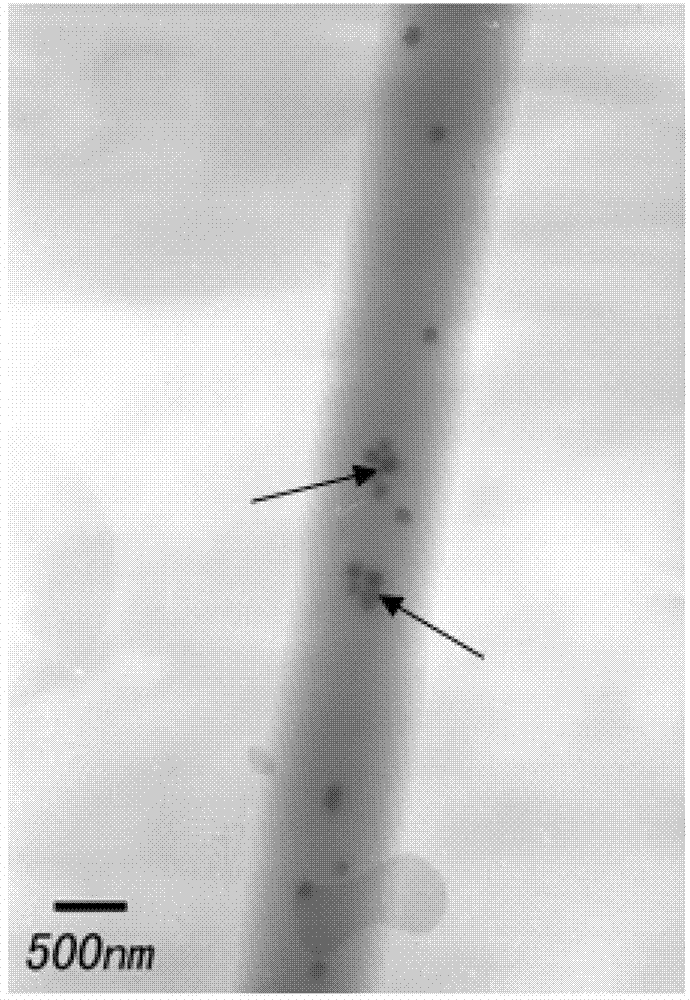

[0035] Silk fibroin nanofiber scaffold loaded with mesoporous silicon

[0036] (1) Preparation of silica nanoparticles by template extraction method: Add 1.0g of template agent (hexadecyltrimethyl) to 500ml of 3% NaOH dilute alkaline aqueous solution, heat the oil bath to 80°C, and stir for 1.5h , add 5 ml of tetraethyl orthosilicate dropwise, wash and centrifuge with deionized water and ethanol, repeat three times and then dry. Reflux in a mixture of 5 ml of 38% HCL and 500 ml of absolute ethanol to remove the template agent to obtain freeze-dried mesoporous silicon;

[0037] (2) Prepare silk fibroin hexafluoroisopropanol solution with a mass volume ratio of 1:5 (g / ml);

[0038] (3) Add 20% of the mass of mesoporous silicon relative to the mass of silk fibroin, draw the solution with a syringe, adjust the voltage to 18kV, push the speed to 0.6ml / h, receive the distance to 20cm, room temperature, and humidity to 60%, Silk fibroin-mesoporous silicon composite nanofibers were ...

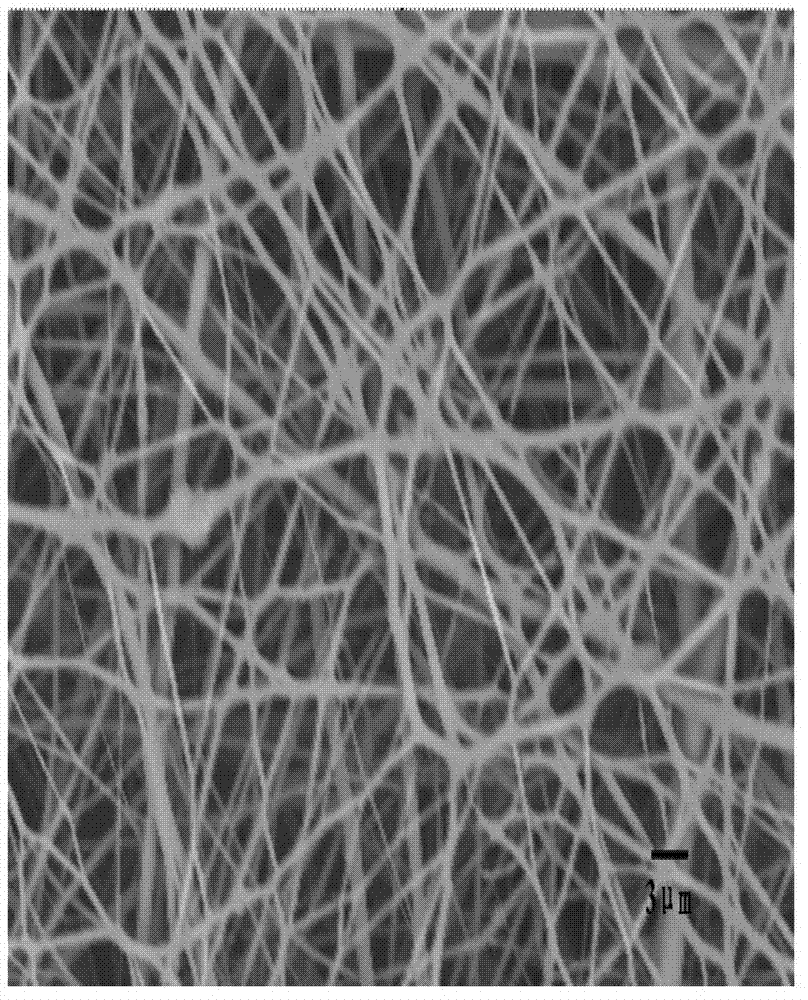

Embodiment 3

[0041] Silk fibroin nanofiber scaffold loaded with mesoporous silicon

[0042](1) Preparation of silica nanoparticles by template extraction method: Add 1.0g of template agent (hexadecyltrimethyl) to 500ml of 3% NaOH dilute alkaline aqueous solution, heat the oil bath to 80°C, and stir for 1.5h , add 5 ml of tetraethyl orthosilicate dropwise, wash and centrifuge with deionized water and ethanol, repeat three times and then dry. Reflux in a mixture of 5 ml of 38% HCL and 500 ml of absolute ethanol to remove the template agent to obtain freeze-dried mesoporous silicon;

[0043] (2) Prepare silk fibroin aqueous solution with a mass volume ratio of 3:10 (g / ml);

[0044] (3) Add the mass of mesoporous silicon equivalent to 15% of the mass of silk fibroin, draw the solution with a syringe, adjust the voltage to 20kV, the advancing speed to 0.3ml / h, the receiving distance to 15cm, the temperature to 30°C, and the humidity to be 50%, the silk fibroin-mesoporous silicon composite nan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com