Biological organic fertilizer containing compound bacteria and preparation method

A bio-organic fertilizer and compound bacteria technology, which is applied in the preparation of organic fertilizers, organic fertilizers, and bio-organic part treatment, etc., can solve the problems of high particle hardness, incomplete fermentation, and long bacterial life, and achieve high hardness and increase bacteria. The effect of prolonging the viability and bacterial life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

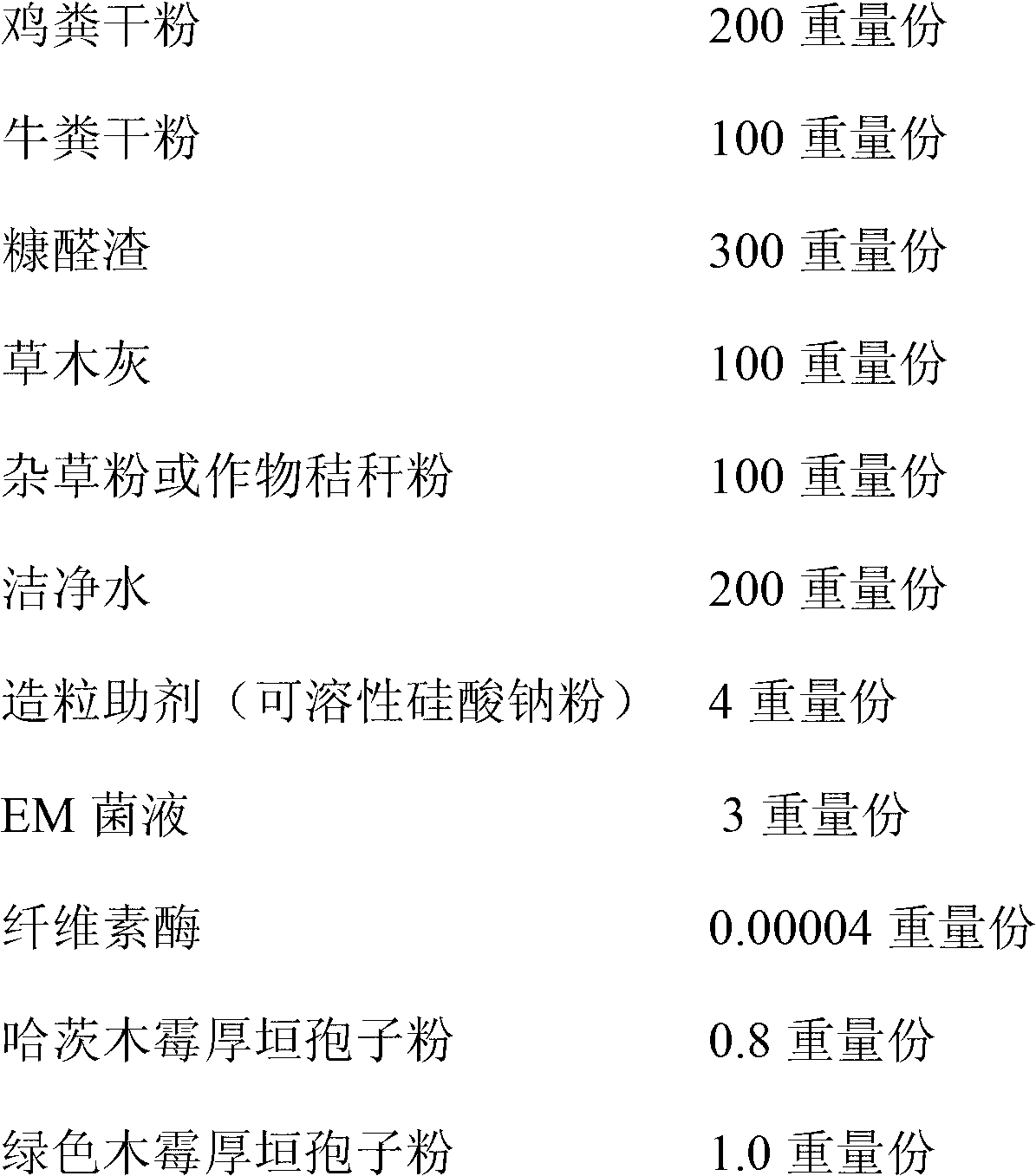

[0022] formula:

[0023]

[0024]

[0025] Preparation:

[0026] Disperse the furfural slag evenly in the fermentation tank (the area of the fermentation tank is determined according to the daily output of the equipment, and the amount of fermentation material in each fermentation tank is not less than the amount of production materials for one day), and then evenly disperse the plant ash in the furfural On the slag, use a compost turner to turn it 2 to 3 times, so that the furfural slag and plant ash are evenly mixed, and then other raw materials containing organic matter are evenly dispersed on the mixture of furfural slag and plant ash. At the same time, the EM bacteria Dissolve the solution and cellulase in a pool filled with clean water, stir to mix evenly, and then spray evenly on the materials in the fermentation tank, then repeat the pile for 5 to 6 times, and cover with a black film to carry out anaerobic fermentation 7 During this period, turn over once a da...

Embodiment 2

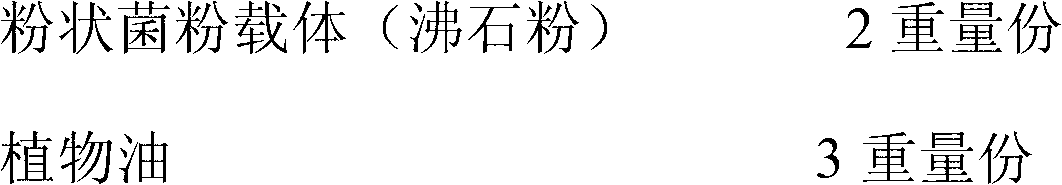

[0030] formula:

[0031]

[0032]

[0033] Preparation method: except raw materials and proportioning, all the other are the same as Example 1. The prepared fertilizer granules have high hardness (hardness 26N), less bacteria (the content of bacteria is less than 10 per gram of finished product), and high bacterial activity rate (the bacterial activity rate is above 96.5%). Bacteria have a long lifespan (more than one and a half years) and comprehensive nutrition (containing nitrogen, phosphorus, potassium, organic matter, calcium, magnesium, sulfur, silicon, selenium, zinc, iron, manganese, copper, boron, molybdenum, etc.).

Embodiment 3

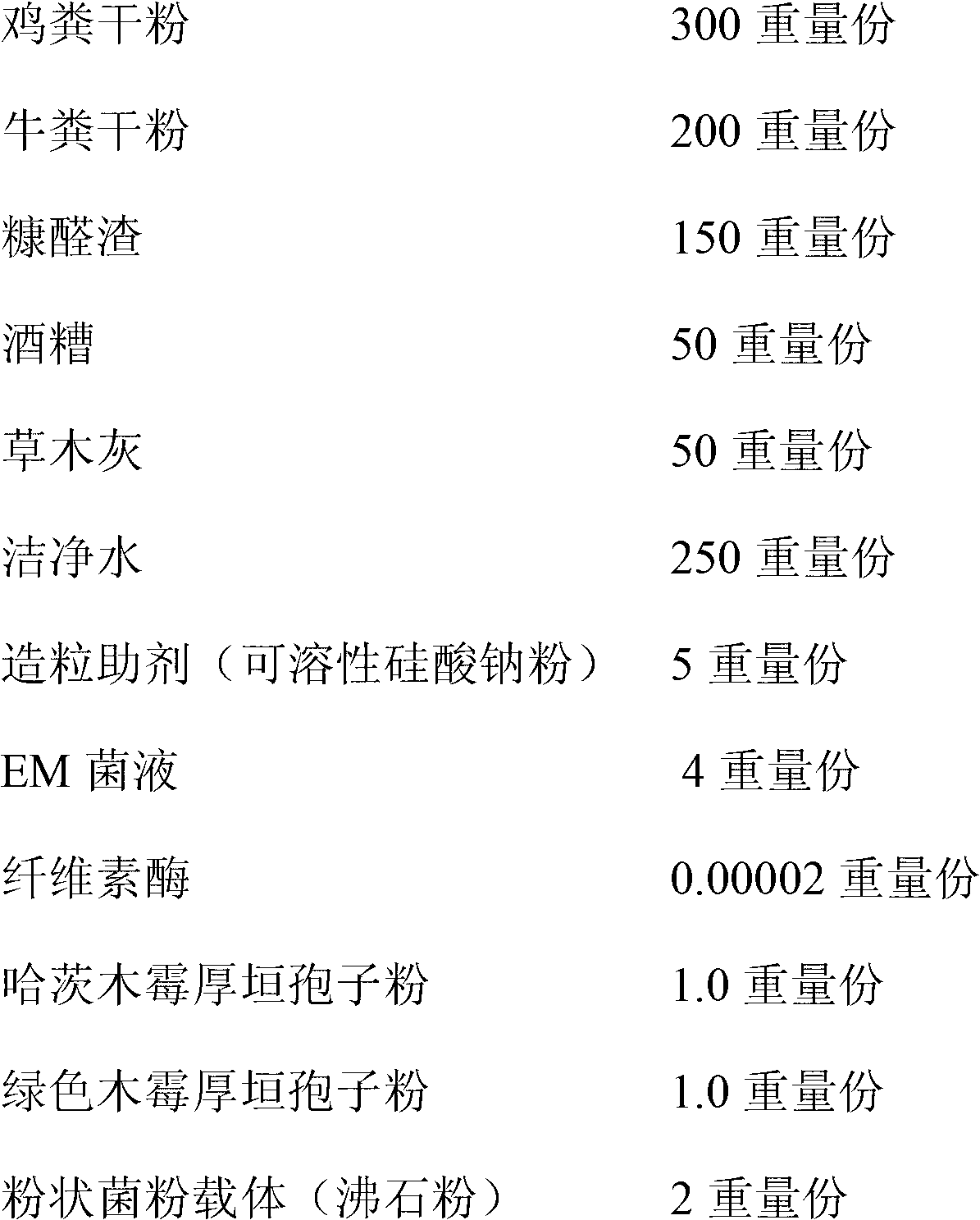

[0035] formula:

[0036]

[0037]Preparation method: except raw materials and proportioning, all the other are the same as Example 1. The fertilizer granules have high hardness (hardness 27N), less bacteria (the content of bacteria is less than 10 per gram of finished product), high bacterial survival rate (97.5%), and long bacterial survival period (the bacterial survival period is more than one and a half years) , comprehensive nutrition (containing nitrogen, phosphorus, potassium, organic matter, calcium, magnesium, sulfur, silicon, selenium, zinc, iron, manganese, copper, boron, molybdenum, etc.).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com