Method for preparing high-performance cellulose/resin composite film by UV curing process

A light-curing resin and resin composite technology, which is applied in the field of preparing regenerated cellulose/resin composite films, can solve the problem that the cellulose fibers are not strictly arranged in one direction, the diameter of electrospun cellulose is not uniform, and the light transmission is affected and mechanical properties, to achieve excellent mechanical properties, simple preparation methods, and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

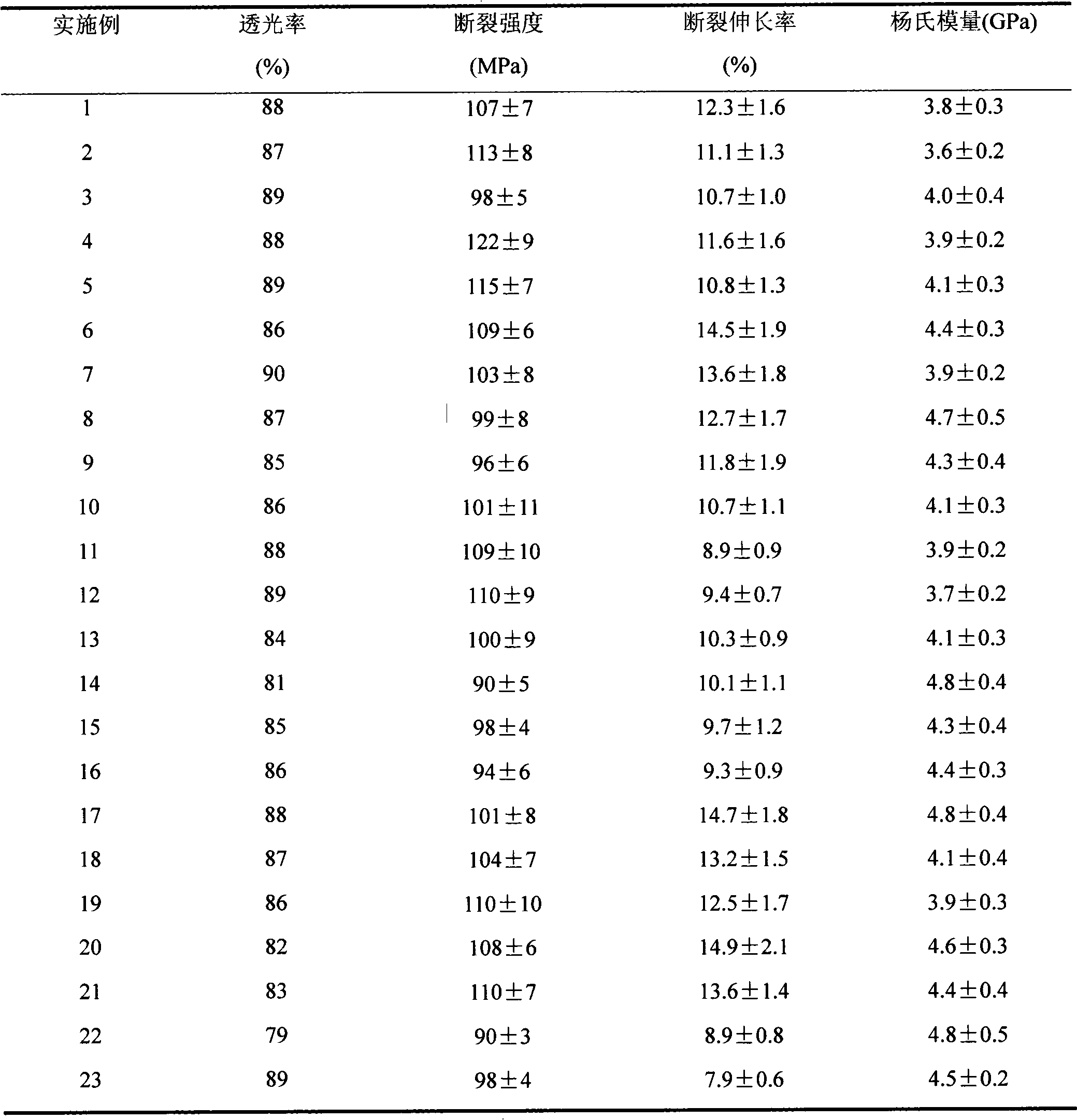

Examples

Embodiment 1

[0018] A regenerated cellulose film was prepared by dissolving natural cellulose with a degree of polymerization of 500 in a NaOH / urea / water (7wt% / 12wt% / 81wt%) solvent system to obtain a 4wt% cellulose solution. The cellulose membrane is washed with water to remove inorganic salts and other impurities, and then the water therein is gradually replaced with acetone solvent. Then it is immersed in polyurethane acrylic resin 6112-100 photocurable resin / photoinitiator 184 (1-hydroxycyclohexyl phenyl ketone) / acetone solution (photocurable resin content 5%, photoinitiator content 2%) 2 Hour. At this point the mixed solution can penetrate into the cellulose membrane. Then it was taken out, cured under ultraviolet light for 10 minutes, and then dried to obtain a cellulose composite film.

Embodiment 2

[0020] Adopt NaOH / urea / water (7wt% / 12wt% / 81wt%) solvent system, method is the same as embodiment 1. The cellulose membrane is washed with water to remove inorganic salts and other impurities, and then the water therein is gradually replaced with acetone solvent. Then it is immersed in polyurethane acrylic resin 6112-100 photocurable resin / photoinitiator 184 (1-hydroxycyclohexyl phenyl ketone) / acetone solution (photocurable resin content 15%, photoinitiator content 3%) 4 Hour. At this point the mixed solution can penetrate into the cellulose membrane. Then it was taken out, cured under ultraviolet light for 20 minutes, and then dried to obtain a cellulose composite film.

Embodiment 3

[0022] Adopt NaOH / urea / water (7wt% / 12wt% / 81wt%) solvent system, method is the same as embodiment 1. The cellulose membrane is washed with water to remove inorganic salts and other impurities, and then the water therein is gradually replaced with acetone solvent. Then it is immersed in polyurethane acrylic resin 6112-100 photocurable resin / photoinitiator 184 (1-hydroxycyclohexyl phenyl ketone) / acetone solution (photocurable resin content 35%, photoinitiator content 3%) 7 Hour. At this point the mixed solution can penetrate into the cellulose membrane. Then it was taken out, cured under ultraviolet light for 30 minutes, and then dried to obtain a cellulose composite film.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com