Catalytic cracking method

A catalyst and cracking reaction technology, which is applied in the field of low-carbon olefin yield, can solve the problem of insufficient selectivity of olefins in methanol conversion rate, and achieve the effects of easy control of dehydration reaction conditions, flexible product solutions, and a wide range of raw materials for processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

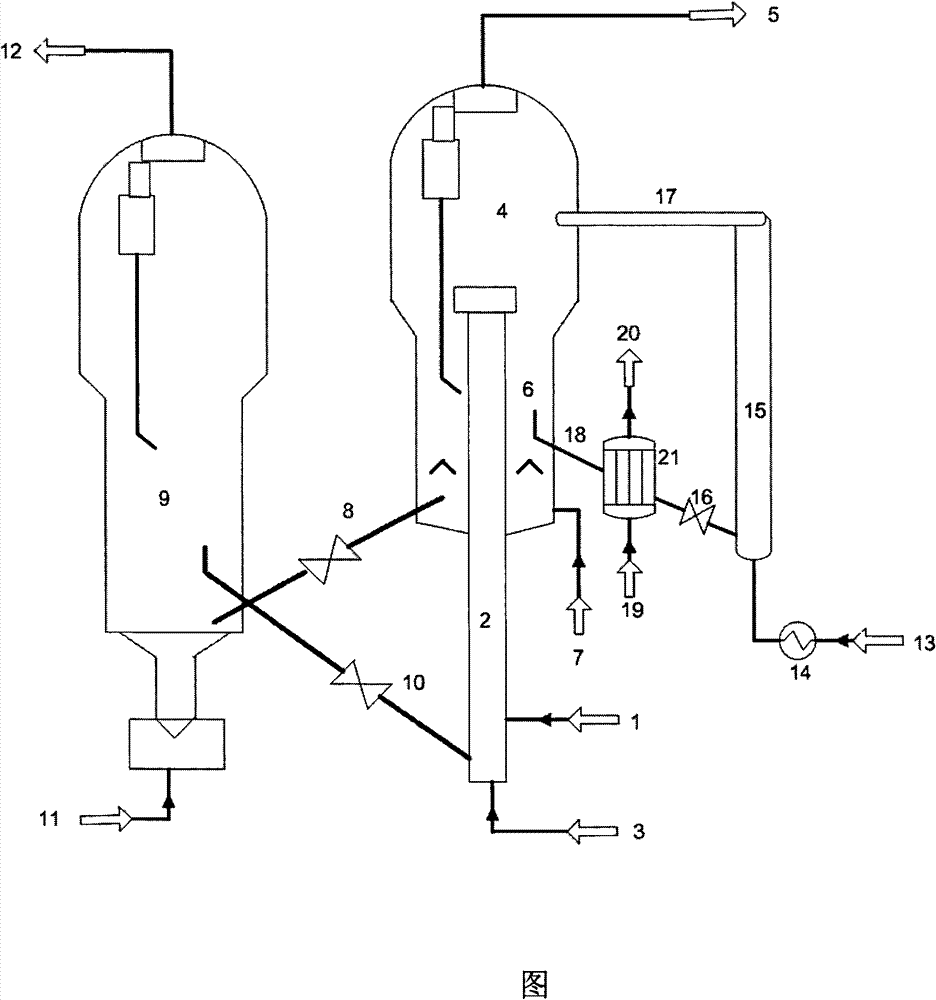

Image

Examples

Embodiment 1

[0058] Example 1 illustrates the catalytic cracking method provided by the present invention.

[0059] The raw material oil for catalytic cracking is Wuhan mixed oil, which is mixed with 70% vacuum wax oil and 30% vacuum residue (see Table 2 for the properties of the raw material). The methanol aqueous solution contains 80% by weight of methanol, and is prepared by adding deionized water to industrial methanol with a purity of 97%.

[0060] Table 2

[0061] project

Density (20℃), g / cm 3

0.9044

Refraction(20℃)

1.5217

Viscosity(100℃)mm 2 / s

9.96

40

Aniline point, ℃

95.8

C wt%

85.98

Hwt%

12.86

S wt%

0.55

N wt%

0.18

Carbon residue wt%

3.0

Distillation range, ℃

initial boiling point

243

5%

294

70%

473

[0062] Catalyst preparation process is as follows: dry ...

Embodiment 2

[0087] Example 2 illustrates the implementation of the catalytic cracking process provided by the present invention on a medium-sized unit operating in continuous reaction-regeneration.

[0088] The catalyst used in the present embodiment, its preparation method is as follows:

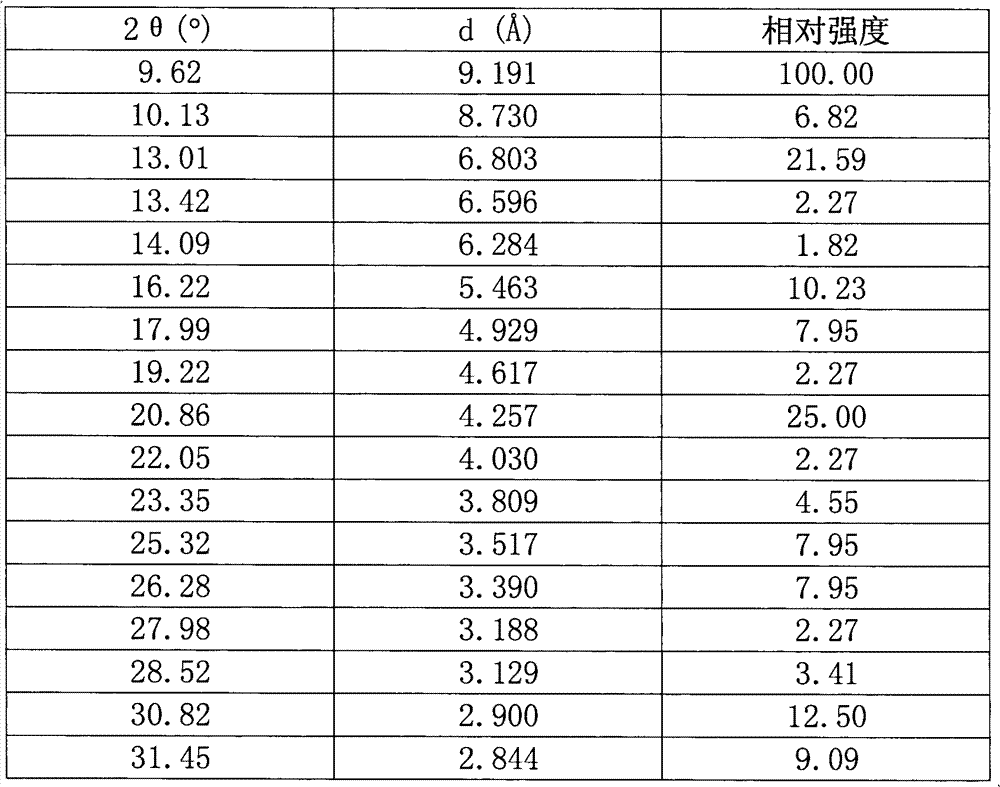

[0089] Add 20kg of ZSP-2 zeolite on a dry basis, add 35kg of deionized water for beating, add 10kg of DASY2.0 molecular sieve, and then add 20kg of SAPO-34 molecular sieve (pilot test product of Sinopec Catalyst Jianchang Branch), and beat evenly. Beat 80 kg of aluminum sol, add 30 kg of kaolin on a dry basis, beat evenly, then add the above-mentioned molecular sieve slurry, beat evenly, spray dry, and collect microsphere particles in the range of 30-150 μm. The catalyst microspheres were calcined at 400°C for 1 h, and then treated with 0.5% NH 4 The Cl aqueous solution was exchanged at 80°C for 0.5h, filtered, washed with water, and dried at 120°C for 16h to obtain the special catalyst B of the prese...

Embodiment 3

[0100] Example 3 illustrates the experimental results of simultaneously injecting methanol and ethanol into the oxygenate dehydration reactor in the catalytic cracking method provided by the present invention.

[0101] The preparation process of the present embodiment catalyst is as follows:

[0102] With dry basis (molecular sieve weight basis, the same below) ZSM-5 zeolite (ZSP-3, iron oxide content 2.5wt%, phosphorus pentoxide content 2.9wt%, Sinopec Catalyst Qilu Branch Company product) 2kg, add 45kg to remove Deionized water beating, add REY molecular sieve (CDY, rare earth oxide content 18.7%, unit cell constant 2.469nm, crystallinity 46%, Sinopec Catalyst Changling branch company product) 35kg, then add SRM molecular sieve (SRM-8, Sinopec Catalyst Jianchang branch product) 15kg, beating evenly. 15Kg pseudo-boehmite (product of Shandong Aluminum Factory of Aluminum Corporation of China, the same below) on a dry basis is added to 100 kg of deionized water for beating, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cell constant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com