Immobilization L-asparaginase reactor

A technology of asparaginase and reactor, which is applied in the direction of enzyme production/bioreactor, biochemical instrument, method of supporting/immobilizing microorganisms, etc. It can solve the problems of poor storage stability, small specific surface area of carrier, and enzyme inactivation, etc. Achieve good biocompatibility, improve the utilization rate and efficiency of enzymes, and simplify the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

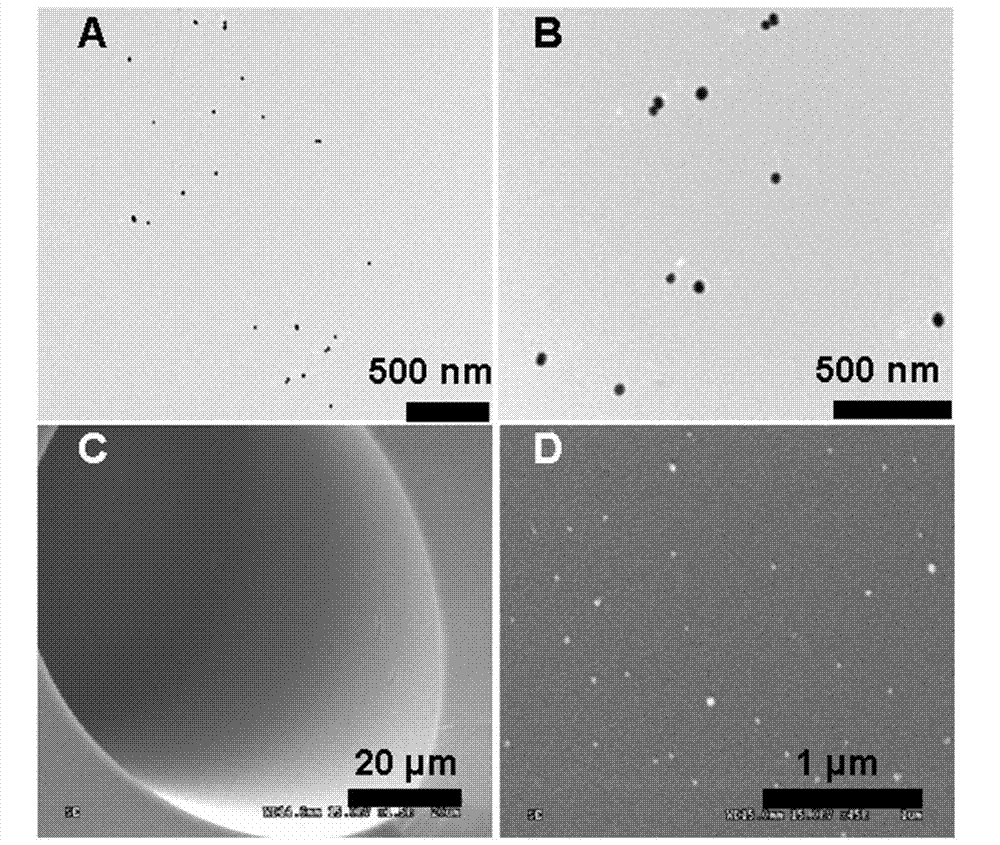

[0029] The preparation method of nano-gold used in the examples is as follows: After boiling chloroauric acid (1.0mM, 10.0mL), quickly add 1.0mL of newly prepared trisodium citrate (38.8mM) solution, and heat while stirring rapidly , the solution turned dark green, and then turned into wine red, and then continued to stir for 10 minutes, and the obtained nano-gold solution was diluted 3 times with triple distilled water for later use.

[0030] The prepared nano-gold has an average particle size of 20nm and a maximum absorption wavelength of 522nm.

[0031] Mix the nano-gold solution and L-asparaginase solution at a ratio of 1:1 (v / v), stir at room temperature for 1 hour, and then place it in a refrigerator at 4°C for 24 hours to obtain L-asparaginase-nano Gold Aggregate Solution.

[0032] Clean capillary tubes (5-50cm) of different lengths: wash with 1.0M sodium hydroxide solution for 2 hours, wash with water for 10 minutes, wash with 1.0M hydrochloric acid solution and water...

Embodiment 1

[0036] Embodiment 1, preparation nano-gold immobilized L-asparaginase reactor

[0037] 1) Mix the nano-gold solution and L-asparaginase solution (concentration 225.0 U / mL) at a ratio of 1:1 (v / v), stir at room temperature for 1 hour, and then place it in a refrigerator at 4°C for 24 hours to obtain L - Asparaginase-gold nano-aggregate solution.

[0038]2) Rinse the 30cm capillary with 1.0M sodium hydroxide solution for 2 hours, water for 10 minutes, 1.0M hydrochloric acid solution and water for 10 minutes, organic solvent acetone for 5 minutes and blow dry with nitrogen. Mix (3-mercaptopropyl)-trimethoxysilane and methanol (volume ratio 1:4), and then the solution flows through the capillary column under negative pressure. After standing at room temperature for 12 hours, it is washed repeatedly with methanol and water to obtain the inner wall modified mercapto group. Capillary column of silane coupling agent, spare.

[0039] 3) The gold nanometer solution-L-asparaginase solu...

Embodiment 2

[0043] Embodiment 2, preparation nano-gold immobilized L-asparaginase reactor

[0044] 1) Mix the nano-gold solution and L-asparaginase solution (4.5U / mL) at a ratio of 1:1 (v / v), stir at room temperature for 1 hour, and then place it in a refrigerator at 4°C for 24 hours to obtain L- Asparaginase-gold nano-aggregate solution.

[0045] 2) Wash the 5cm capillary with 1.0M sodium hydroxide solution for 2 hours, rinse with water for 10 minutes, wash with 1.0M hydrochloric acid solution and water for 10 minutes in sequence, rinse with organic solvent acetone for 5 minutes, and then blow dry with nitrogen. Mix (3-mercaptopropyl)-trimethoxysilane and methanol (volume ratio 1:4), and then the solution flows through the capillary column under negative pressure and fully contacts with its inner wall. After standing at room temperature for 12 hours, rinse with methanol and water repeatedly , that is, a capillary column with an inner wall modified mercaptosilane coupling agent is obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com