High-fat powder grease and preparation method thereof

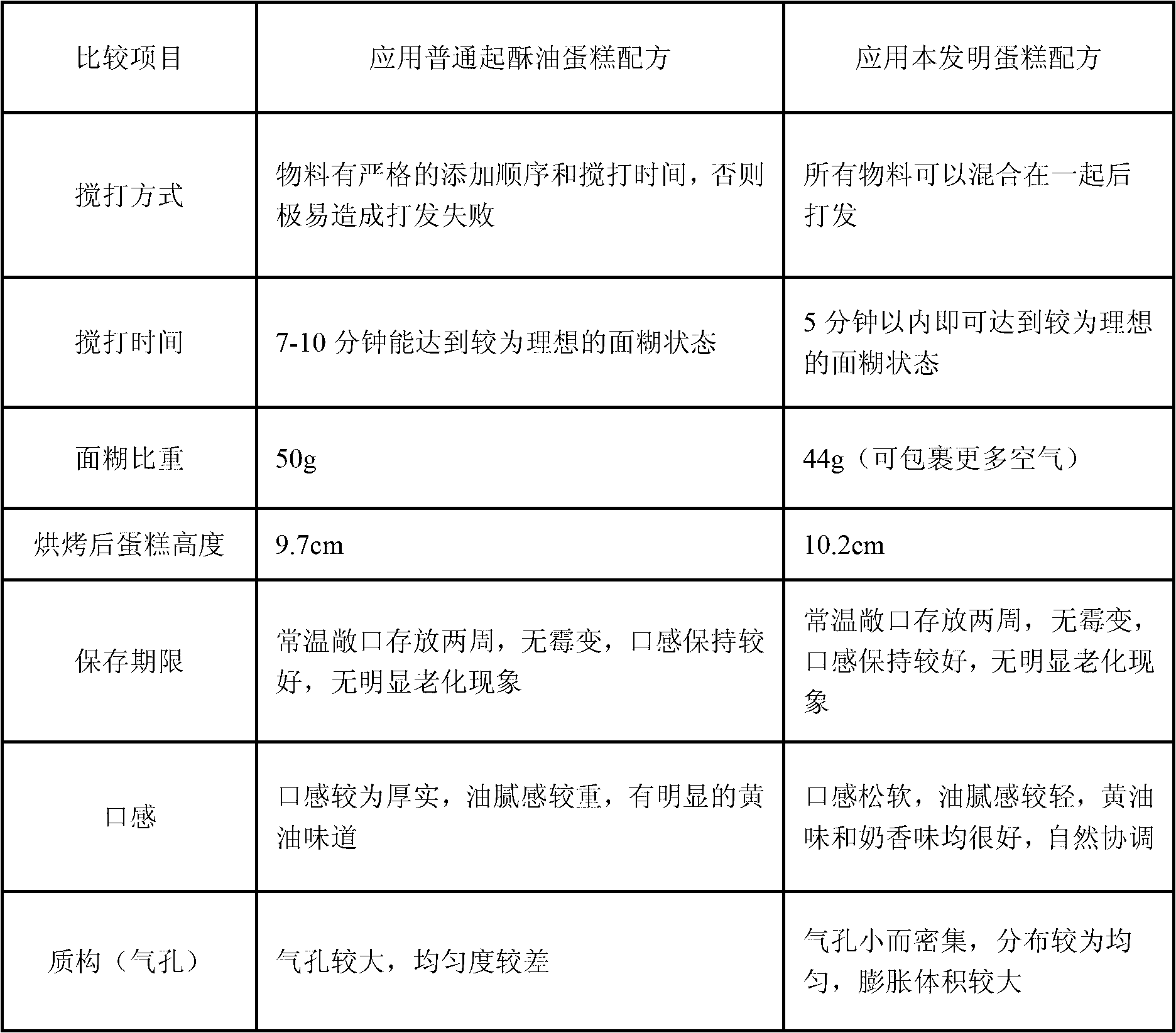

A technology of oil and fat powder, which is applied in the field of high-fat powder oil and its preparation, can solve the problems of single functional characteristics, etc., and achieve the effects of multiple product changes, enhanced crisping performance, and high embedding rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1, general purpose powder shortening

[0033] Raw materials and composition (weight percent):

[0034] Hydrogenated soybean oil, 70%; Hydrogenated palm stearin, 12%; Mono- and diglycerides of fatty acids, 2.5%; Diacetyl tartrate mono-diglycerides 1.5%; Sodium stearoyl lactylate, 2%; Polysorbate, 2% %; Lactic acid and fatty acid glycerides, 1%; Sodium caseinate, 2%; Malt syrup, 5.8%; Dipotassium hydrogen phosphate, 1%; Silicon dioxide, 0.2%.

[0035] Production Process:

[0036] 1. Weigh the above raw materials in proportion, preheat a certain amount of deionized water, raise the temperature to above 70°C, then slowly put the weighed dipotassium hydrogen phosphate and sodium caseinate into hot water, and stir quickly Dissolve, then add malt syrup and stir evenly to prepare the water phase for later use.

[0037] 2. Mix the oil and heat it to 70°C, then add the emulsifier to dissolve the emulsifier, and prepare the oil phase for later use.

[0038] 3. Mix a...

Embodiment 2

[0045] Embodiment 2, special powdered shortening for bread and cake

[0046] Raw material and composition:

[0047]Hydrogenated Soybean Oil, 38%; Hydrogenated Palm Oil, 25.5%; Soybean Salad Oil, 12%; Lard, 8.5%; Mono- and Diglycerides of Fatty Acids, 2.5%; Ester 1.5%; Succinic Glyceryl Fatty Acid Ester, 1.5%; Polyglyceryl Fatty Acid Ester, 0.5%; Fatty Acid Sorbitan Ester, 0.5%; Sodium Caseinate, 2%; Maltose Syrup, 4.8%; , 1%; sodium citrate, 0.5%, silicon dioxide, 0.2%.

[0048] Production Process:

[0049] 1. Weigh the above raw materials in proportion, preheat a certain amount of deionized water, raise the temperature to above 70°C, and then slowly put the weighed sodium citrate, dipotassium hydrogen phosphate and sodium caseinate into hot water , stir quickly to dissolve, then add maltose syrup and stir evenly, and prepare the water phase for later use.

[0050] 2. Heat the oil to 70°C after mixing, dissolve the emulsifier, and prepare the oil phase for later use.

[0...

Embodiment 3

[0064] Raw material and composition:

[0065] Hydrogenated Soybean Oil, 38%; Hydrogenated Palm Oil, 25%; Coconut Oil, 26%; Mono- and Diglycerides of Fatty Acids, 2.0%; Syrup, 5%; Dipotassium hydrogen phosphate, 0.2%; Sodium citrate, 0.5%, Silicon dioxide, 0.3%.

[0066] Preparation method is with embodiment 1.

[0067] After testing, the average embedding rate of this spray product is 89%, which is much higher than the embedding rate (lower than 70%) under the oil content of emulsifier combinations listed in other inventions. After being stored at 25°C for 3 months, the surface oil content of the product is about 13.5%, indicating that the powdered oil has good stability during storage and is suitable for long-term storage. At the same time, the fluidity of products stored for more than 3 months is still very good, and there is no agglomeration or agglomeration under normal stacking conditions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com