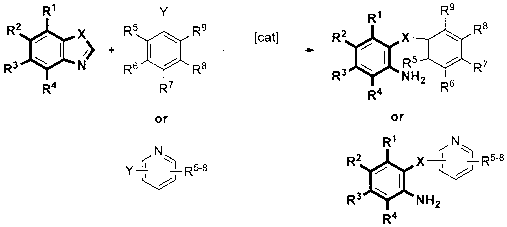

Method for synthesizing o-amino diaryl ether and o-amino diaryl sulfur ether

A technology of o-amino diaryl sulfide and o-amino diaryl ether, which is applied in chemical instruments and methods, formation/introduction of amino groups, preparation of amino hydroxy compounds, etc. problem, to achieve the effect of direct reaction, simple method and good activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

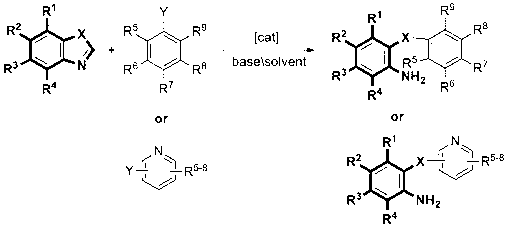

Method used

Image

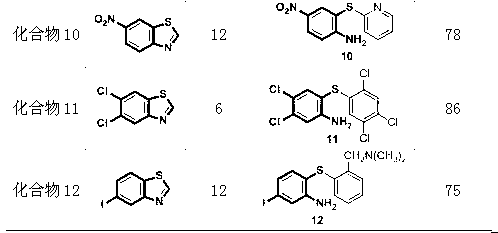

Examples

Embodiment 1

[0039] Compound 1: Add metal copper powder (0.05mmol), cesium carbonate (1.0mmol) and polyethylene glycol-600 (2.0g) into a 25mL reaction flask, fill with nitrogen protection, add benzothiazole (0.5mmol) and iodobenzene (1.0 mmol). The reaction mixture was at 140 o Reaction at C until the reaction of the raw materials is complete. After cooling to room temperature, the solvent was evaporated under reduced pressure and separated by column chromatography (petroleum ether: diethyl ether: triethylamine = 30: 1: 1) to obtain a pale yellow liquid. Yield 96%.

Embodiment 2

[0041] Compound 2: Add metal copper powder (0.05mmol), cesium carbonate (1.0mmol) and polyethylene glycol-600 (2.0g) into a 25mL reaction flask, fill with nitrogen protection, add benzothiazole (0.5mmol) and o-iodine Toluene (1.0 mmol). The reaction mixture was at 140 o Reaction at C until the reaction of the raw materials is complete. After cooling to room temperature, the solvent was evaporated under reduced pressure and separated by column chromatography (petroleum ether: diethyl ether: triethylamine = 30: 1: 1) to obtain a pale yellow liquid. Yield 94%.

Embodiment 3

[0043] Compound 3: Add metal copper powder (0.05mmol), sodium carbonate (1.0mmol) and polyethylene glycol-400 (2.0g) to a 25mL reaction flask, fill with nitrogen protection, add benzothiazole (0.5mmol) and p-iodine Aniline (1.0 mmol). The reaction mixture was at 140 o Reaction at C until the reaction of the raw materials is complete. After cooling to room temperature, the solvent was evaporated under reduced pressure and separated by column chromatography (petroleum ether: diethyl ether: triethylamine = 30: 1: 1) to obtain a pale yellow liquid. Yield 93%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com