Treating method of arsenious material

A treatment method and material technology, applied in the field of smelting and processing, can solve problems such as environmental pollution, achieve the effects of solving environmental pollution, reducing environmental pollution, and improving comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

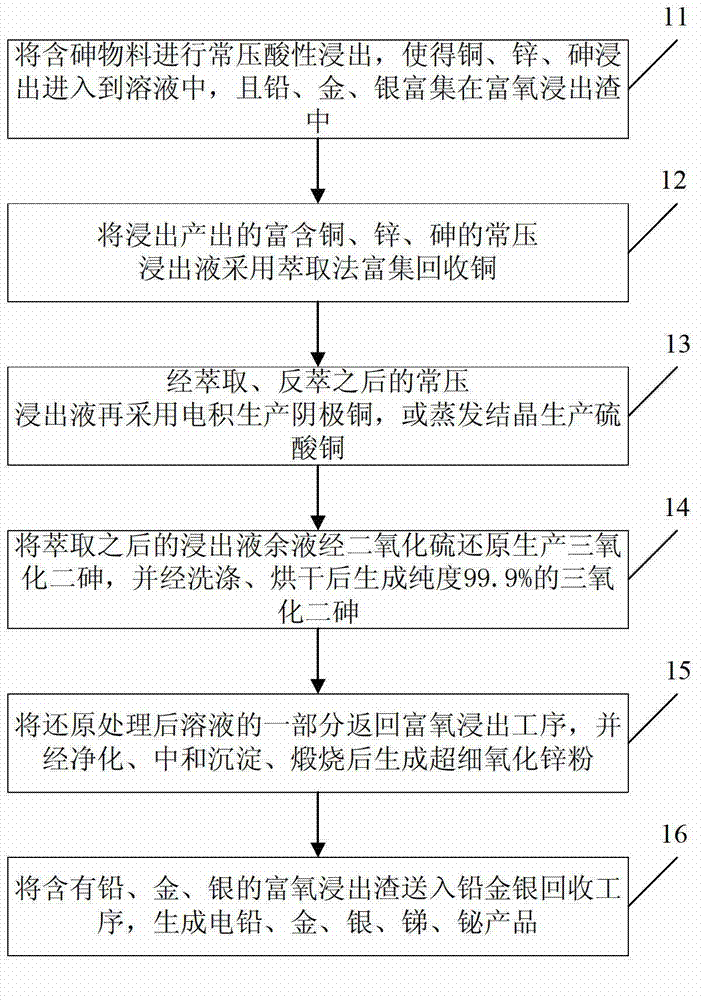

Method used

Image

Examples

Embodiment 1

[0044]Weigh 20g of black copper mud (Cu52%, As 19%), add sulfuric acid at 70~80°C for normal pressure stirring and leaching, the reaction time is 2h, after the reaction, the pulp and arsenic sulfide residue (Cu 8%, As 22%, Zn 0.8, S 30%) 100g slurry, then carry out oxygen-enriched leaching, control the reaction temperature at 150°C, and the reaction time is 2h, the leaching rates of copper, arsenic and zinc all reach above 95%.

[0045] The pressurized leaching solution was extracted with Lix984N to extract copper, and the loaded organic phase was back-extracted with sulfuric acid to obtain a copper sulfate solution. The copper extraction rate reached more than 98%. The copper sulfate solution was evaporated and crystallized to produce copper sulfate, and 68.5g of copper sulfate was produced.

[0046] The leaching residue produced by the above-mentioned black copper mud is 50.3g, of which the sulfur grade is above 60%. The raffinate is then reduced by sulfur dioxide, cooled and...

Embodiment 2

[0049] The intermediate material (Cu 4.02%, S 10.61%, Zn 9.28%, As 8.23, Pb9.24%, Au 1.58g / t, Ag 161.3g / t) produced during the mineral smelting process, weighed 200g of the arsenic-containing material, Direct leaching was carried out at 85°C, the leaching slag rate was 45%, and the leaching rates of copper, zinc and arsenic were 50%, 85% and 50% respectively.

[0050] After leaching, the pulp was subjected to acidic oxygen-enriched leaching at 110°C. The copper leaching rate reached over 96%, the arsenic leaching rate reached over 95%, and the zinc leaching rate reached over 98%, and 81.2g of leaching slag was produced.

[0051] The leaching solution is extracted with lix984 to extract copper, and the loaded organic phase extraction is used to produce copper sulfate.

[0052] The sulfur dioxide in the raffinate is reduced to produce arsenic trioxide, and the liquid after dearsenization is purified, neutralized and precipitated, and calcined to produce ultrafine zinc oxide powd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com