Preparation method of oxidized bagasse xylan

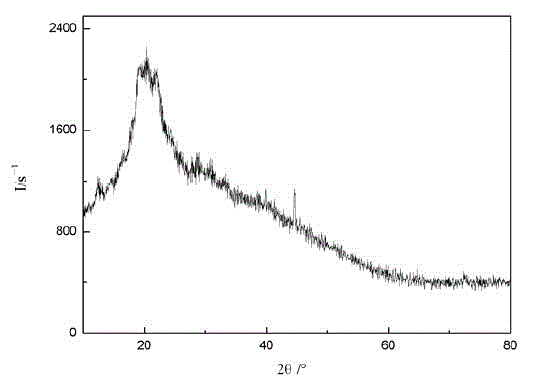

A technology of xylan and bagasse, which is applied in the field of preparation of oxidized bagasse xylan, can solve the problems of low oxidation depth and affecting product performance, and achieve high oxidation depth, improved hydrophobicity, high crystallinity and crystallization area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

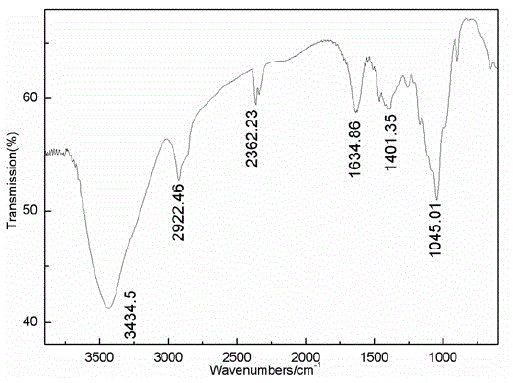

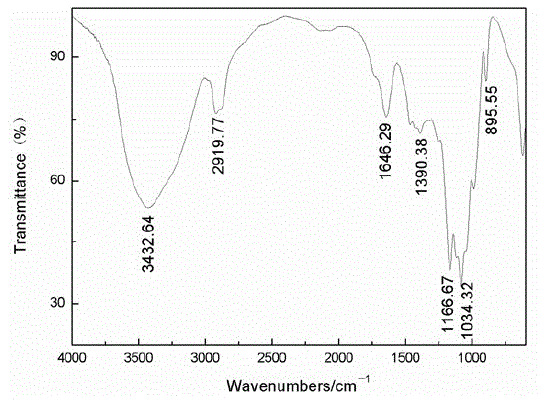

Image

Examples

Embodiment 1

[0031] (1) Dry bagasse xylan in a vacuum oven at 60°C to constant weight to obtain powdery dry basis bagasse xylan.

[0032] (2) Add 10 g of powdered dry-based bagasse xylan and 22 g of analytically pure acetone obtained in step (1) into the reactor to prepare a xylan suspension with a mass fraction of 32%.

[0033] (3) Weigh 0.4g of sodium hydroxide and dissolve it in 7.5mL of deionized water, then add it into the xylan suspension obtained in step (2), stir and activate for 1 hour.

[0034] (4) Dissolve 0.2g of potassium permanganate in 10 mL of deionized water and add to the material obtained in step (3), then add 0.3g of catalyst nickel sulfate, control the reaction temperature of the system to 55°C, and carry out the oxidation reaction under stirring. Add 1 mL of 5% sodium hydroxide solution every 20 minutes to maintain the pH of the system at 9, and react for 4 hours until the system changes from purple to brown.

[0035] (5) Add concentrated sulfuric acid with a mass fr...

Embodiment 2

[0041] (1) Dry bagasse xylan in a vacuum oven at 60°C to constant weight to obtain powdery dry basis bagasse xylan.

[0042] (2) Add 13g of powdered dry-based bagasse xylan and 24g of analytically pure acetone obtained in step (1) into the reactor to prepare a xylan suspension with a mass fraction of 35%.

[0043] (3) Weigh 0.5g of sodium hydroxide and dissolve it in 10mL of deionized water, then add it into the xylan suspension obtained in step (2), stir and activate for 1 hour.

[0044] (4) Dissolve 0.4g of potassium permanganate in 15 mL of deionized water and add it to the material obtained in step (3), then add 0.2g of catalyst nickel sulfate, control the reaction temperature of the system at 60°C, and carry out the oxidation reaction under stirring; Add 1 mL of 10% sodium hydroxide solution in 20 minutes to maintain the pH of the system at 10, and react for 5 hours until the system changes from purple to brown.

[0045] (5) Add concentrated sulfuric acid with a mass fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com