A conductive polymer polyaniline/manganese trioxide composite coating with strong adhesion and its preparation method

A technology of manganese trioxide and conductive polymers, which is applied in coatings, metal material coating processes, anti-corrosion coatings, etc., and can solve problems such as lack of adhesion, less conductive polyaniline film materials, and poor adhesion of coatings to substrates, etc. problems, to achieve the effect of intact film layer, good anti-corrosion performance and good bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The preparation method of the conductive polymer polyaniline / manganese trioxide composite coating with strong adhesion includes the growth of zinc oxide nanorods and the preparation of the composite coating. The specific process is as follows:

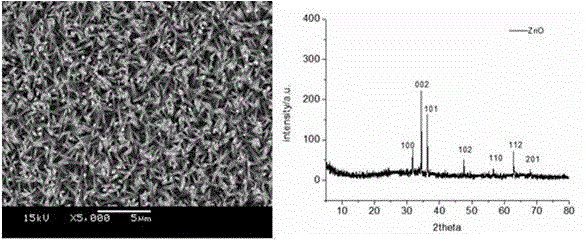

[0028] Prepare raw material spherical manganese trioxide for later use: Weigh 12.25 g of manganese acetate, 9.16 g of urea (manganese acetate: urea = 1:3) and 5 g of PEG-500, dissolve them in 110 ml of ethylene glycol, and The solution was transferred to a hydrothermal reactor, reacted at a temperature of 200 °C for 20 h, and then cooled naturally. Then the product was washed and then calcined at 500°C for 8 h to obtain Mn 2 o 3Micro-nano hollow spheres (see figure 2 ).

[0029] Preparation of raw polyaniline for later use: First, take 1~5ml of aniline monomer and put it in a beaker, add 50~90ml of 1mol / L hydrochloric acid solution and mix well for later use; then take 1~10g of ammonium persulfate as an oxidant, add 50~100ml...

Embodiment 2

[0033] The first step, ZnO nanorod growth: take a clean beaker, add 1~20 ml 0.2 mol / L Zn(Ac) into it 2 , and 1~20 ml 0.4 mol / L NaCl, and add deionized water to dilute. The Zn sheet with the passivation layer removed and the surface-treated carbon steel sheet are coupled with a wire and put into the electrolyte. React at a temperature of 80° C. for 3 hours, at which point the nano zinc oxide rods have covered the surface of the carbon steel.

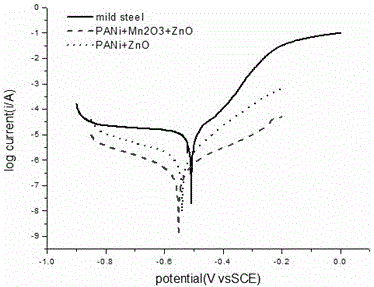

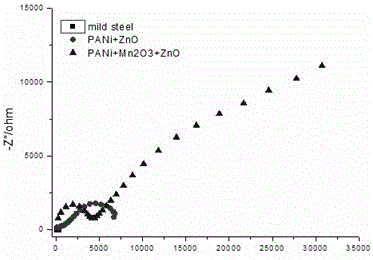

[0034] The second step, the preparation of the composite coating: weigh 0.1 g of polyaniline into a transparent vial, and weigh 0.003 g of the aforementioned Mn 2 o 3 Put in a bottle and add a stir bar. Add 2 ml of nitrogen-methylpyrrolidone into the vial, use an ultrasonic instrument to ultrasonically oscillate for 0.5 h, then magnetically stir at room temperature for 24 h, and then ultrasonically oscillate for 0.5 h. At this time, polyaniline and Mn 2 o 3 The particles are uniformly mixed to obtain a polyaniline nanocomposite coat...

Embodiment 3

[0036] The first step, ZnO nanorod growth: take a clean beaker, add 1~20 ml 0.2 mol / L Zn(Ac) into it 2 , and 1~20 ml 0.4 mol / L NaCl, and add deionized water to dilute. The Zn sheet with the passivation layer removed and the surface-treated carbon steel sheet are coupled with a wire and put into the electrolyte. React at a temperature of 80° C. for 3 hours, at which point the nano zinc oxide rods have covered the surface of the carbon steel.

[0037] The second step, the preparation of the composite coating: weigh 0.1 g of polyaniline into a transparent vial, and weigh 0.007 g of the aforementioned Mn 2 o 3 Put in a bottle and add a stir bar. Add 2 ml of nitrogen-methylpyrrolidone into the vial, use an ultrasonic instrument to ultrasonically oscillate for 0.5 h, then magnetically stir at room temperature for 24 h, and then ultrasonically oscillate for 0.5 h. At this time, polyaniline and Mn 2 o 3 The particles are uniformly mixed to obtain a polyaniline nanocomposite coat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com