Single crystal graphene pn node and preparation method thereof

A single crystal graphene, pn junction technology, applied in graphene, single crystal growth, single crystal growth, etc., can solve the problems of unfavorable scale expansion, poor use stability, etc., and achieve high mobility and high photoelectric conversion efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

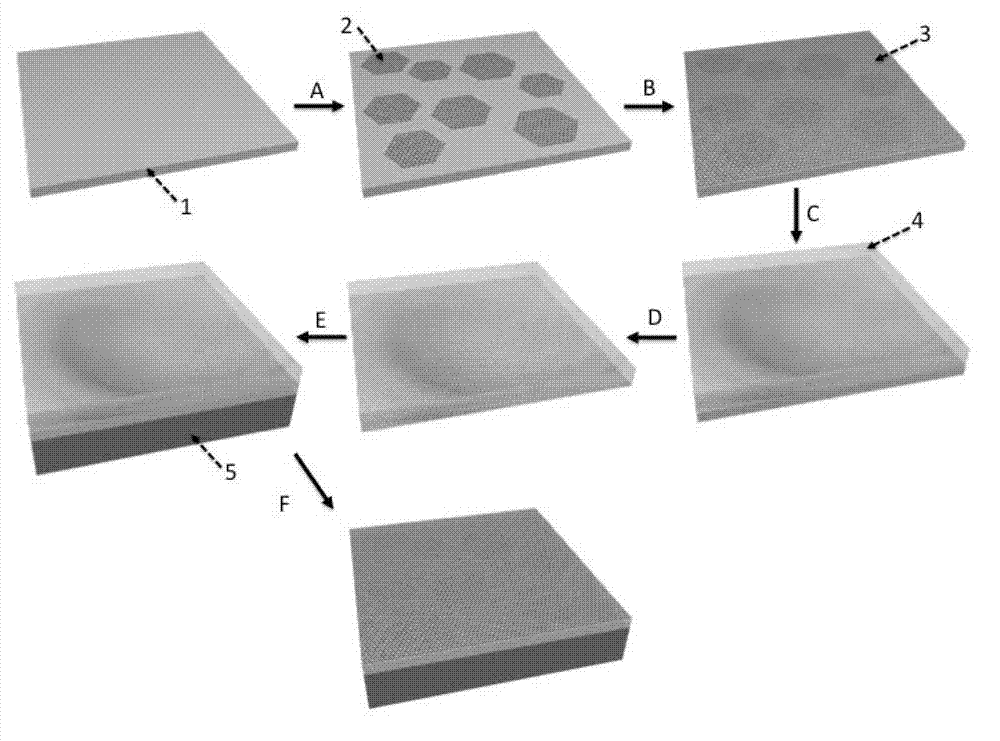

[0040] Example 1, single modulation to prepare single-level single-crystal graphene pn junction

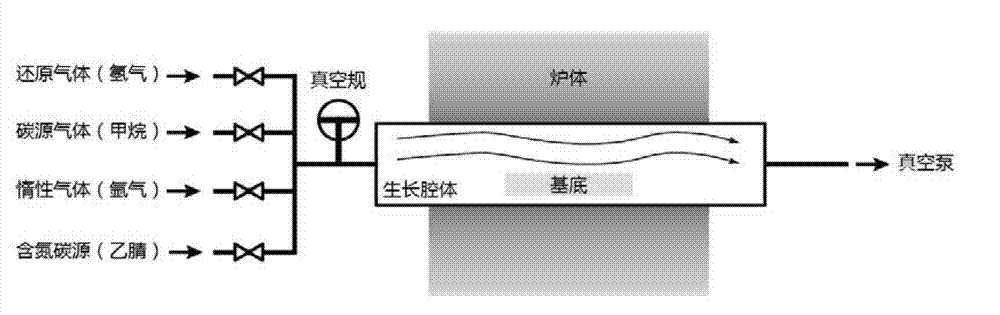

[0041]1) Use 5% dilute hydrochloric acid and deionized water to clean the copper foil (produced by Alfa Aesar, with a purity of 99.8%, and a thickness of 25 μm) in sequence, and place the copper foil in a sleeve with a magnetic control device, and then place the sleeve The tube is placed in a tube furnace, and the temperature of the furnace body is raised to 1020°C under a hydrogen atmosphere with a flow rate of 5 sccm, and the system pressure is about 10 Pa, and kept for 30 minutes;

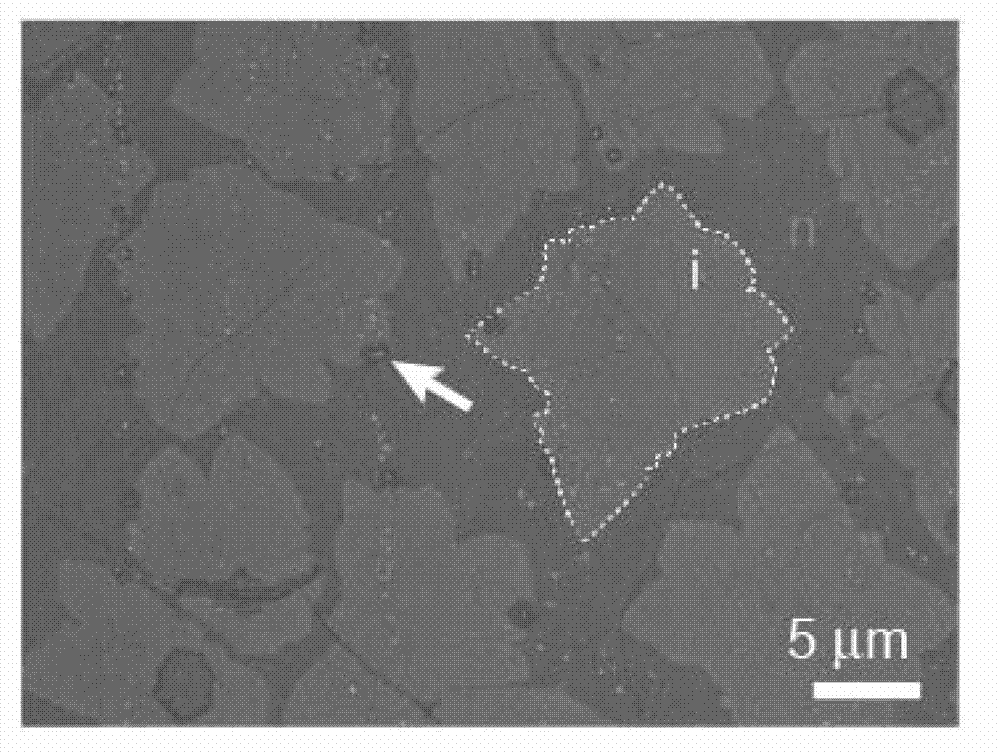

[0042] 2) Lower the temperature of the furnace body to 1000°C, keep the flow rate of hydrogen gas constant, feed methane gas with a flow rate of 5 sccm, keep it for 30 seconds, and the system pressure is about 20 Pa to complete the growth of intrinsic graphene islands, the size of which is 2- 20μm;

[0043] 3) Keep the flow rate of hydrogen gas constant, turn off the methane gas, feed argon gas wit...

Embodiment 2

[0053] Embodiment 2, three-time modulation prepares multilevel graphene pn junction

[0054] 1) step is with embodiment 1 step 1);

[0055] 2) Adjust the temperature of the furnace body to 980°C, keep the flow rate of hydrogen gas constant, feed in methane gas with a flow rate of 5 sccm, keep it for 10 seconds, and the system pressure is about 20 Pa to complete the growth of intrinsic graphene, whose size is 2-5 μm;

[0056] 3) Keep the temperature of the furnace body and the flow rate of hydrogen gas constant, turn off the methane gas, feed in argon gas with a flow rate of 200 sccm, keep it for 3 minutes, and lower the temperature of the furnace body to 900°C while feeding in argon gas;

[0057] 4) Stabilize the temperature of the furnace body at 900°C, keep the hydrogen flow constant, turn off the argon gas, open the needle valve for controlling the acetonitrile vapor, keep the partial pressure of acetonitrile at 5Pa, and grow for 10s to complete the growth of nitrogen-doped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com