Preparation method of hollow superparamagnetic nanospheres

A magnetic nanosphere, superparamagnetic technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problems of low saturation magnetization and large magnetic particle size, and achieve high superparamagnetic Responsiveness, small particle size and controllable particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

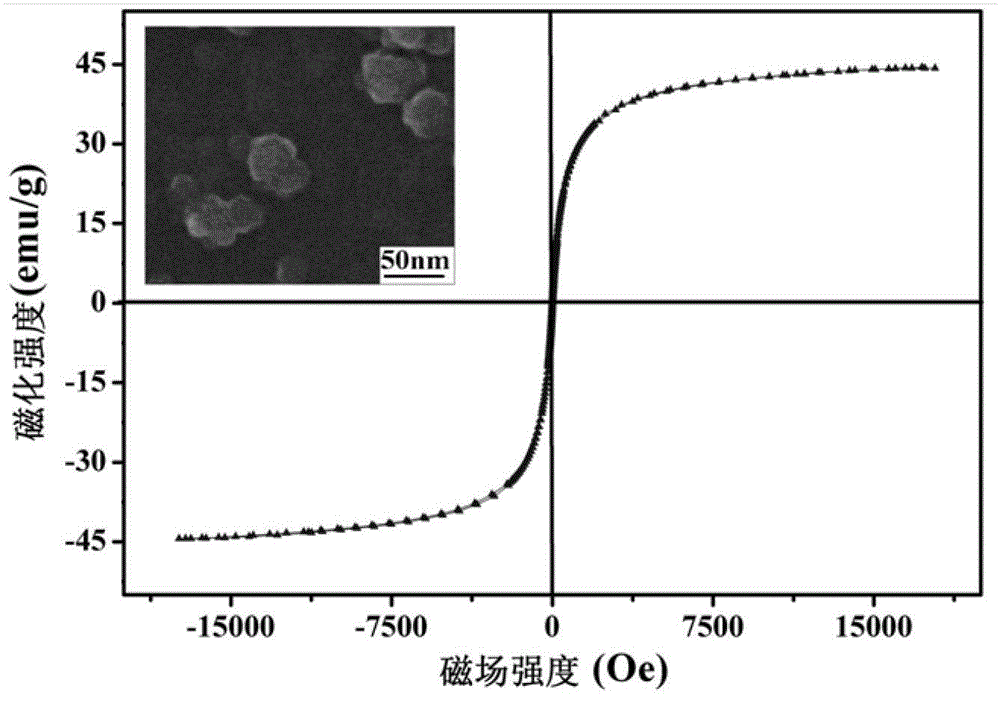

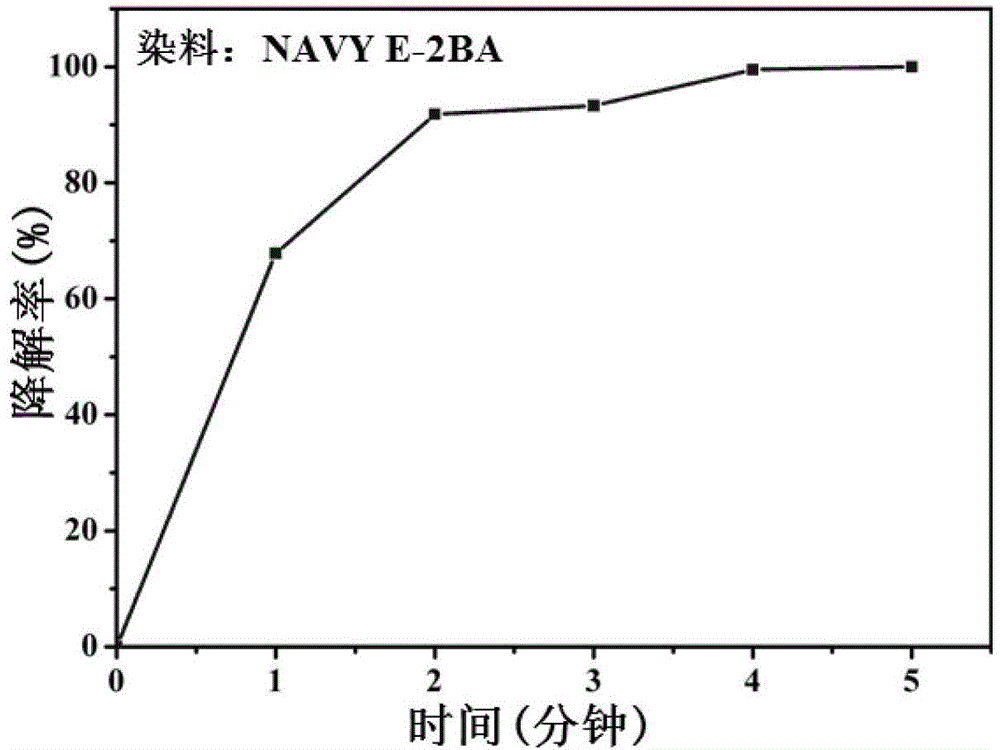

[0026] Soak 2g of lyocell cellulose in NaOH solution with a concentration of 1mol / L for 30min, take it out and wash it, then immerse it in 50ml of 1mol / L ammonium persulfate aqueous solution, hydrolyze it at 60°C for 12h, centrifuge and wash it until neutral, then pass Grading to obtain relatively uniform carboxylated cellulose nanospheres; then disperse the above-mentioned cellulose nanospheres in 100ml water, the solid content is 10g / L; first add 7ml ethanol, then add 0.54g FeCl 3 and 0.28g FeSO 4 7H 2 O, after stirring for 15 minutes, add 10ml, 2.5mol / L ammonia solution, react at 20°C for 1h, then collect the product with a magnet, wash it and send it to a muffle furnace, and calcine it at 600°C for 30min under the protection of nitrogen to obtain Hollow superparamagnetic nanospheres with a size of about 48nm and a magnetic strength of 45emu / g (such as figure 1 shown). Weigh 0.01g composite material, measure 5mL 30% H 2 o 2 , added to 4mL NAVY E-2BA dye solution with ...

Embodiment 2

[0028] Soak 3g of viscose fiber in NaOH solution with a concentration of 1mol / L for 40min, take it out and wash it, then immerse it in 100ml of ammonium persulfate aqueous solution with a concentration of 2.5mol / L, hydrolyze it at 90°C for 16h, and the product is centrifuged and washed to medium After sizing, obtain relatively uniform carboxylated cellulose nanospheres by classification; then disperse the above-mentioned cellulose nanospheres in 80ml of water, and its solid content is 15g / L; first add 3ml glycerol, and then add 0.54g FeCl 3 and 0.28g FeSO 4 7H 2O, after stirring for 10 minutes, add 10ml, 2.5mol / L ammonia solution, react at 60°C for 5h, then collect the product with a magnet, clean it and send it to a muffle furnace, and calcine at 800°C for 30min under nitrogen protection to obtain Hollow superparamagnetic nanospheres with a size of about 61nm and a magnetic strength of 48emu / g. Weigh 0.02g of the composite material, add it to 100mL of 10mg / L copper ion solu...

Embodiment 3

[0030] Soak 2g of lyocell fiber in NaOH solution with a concentration of 1mol / L for 60min, take it out and wash it, then immerse it in 100ml of potassium permanganate aqueous solution with a concentration of 1mol / L, hydrolyze it at 85℃ for 8h, and the product is centrifuged and washed to neutral Finally, obtain relatively uniform carboxylated cellulose nanospheres by classification; then disperse the above-mentioned cellulose nanospheres in 70ml water, and its solid content is 15g / L; first add 4ml ethylene glycol, then 0.27g FeCl 3 and 0.14g FeSO 4 7H 2 O, after stirring for 10 minutes, add 10ml, 2.5mol / L ammonia solution, react for 3 hours, collect the product with a magnet, clean it and put it into a muffle furnace, and calcinate at 1000°C for 30 minutes under the protection of nitrogen to obtain a size of 32nm The left and right hollow superparamagnetic nanospheres have a magnetic strength of 38emu / g. Weigh 0.1g composite material, measure 5mL 30% H 2 o 2 , sequentially...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com